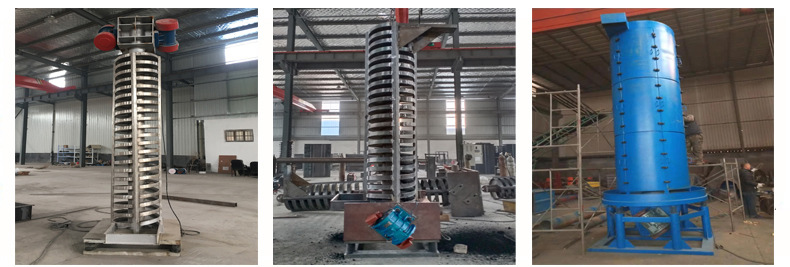

Stainless steel vertical vibration elevator is made of 304 stainless steel to ensure that the product is not contaminated. It is suitable for conveying various small particles, mixtures and powders in the food and pharmaceutical industries. It adopts a 90° angle and vertical vertical feeding. Air-cooled, water-cooled, exhausted and other styles can be designed according to material characteristics.

Stainless steel vertical vibration elevator is suitable for the transportation of granular, massive and powdery solid materials that have strict hygiene requirements for food, medicine, etc., or are corrosive.

When the stainless steel vertical vibration elevator is working, according to the self-synchronization principle of the double vibration motor, the vibration motor generates the exciting force, which forces the entire conveying tower body to perform a spatial compound vibration of horizontal circular motion and upward vertical motion, and the materials in the spiral groove are subjected to vibration. The function of the conveying trough makes a uniform throwing circular motion and moves upward along the conveying trough body to complete the upward (or downward) conveying of materials. Therefore, this equipment is also called a vibrating vertical conveyor.

1. 304 stainless steel material, suitable for conveying materials with strict hygiene requirements or acid and alkali, such as food, medicine or chemical industries.

2. Vertical upward conveying, the conveying height can reach 8 meters.

3. It can also cool down while lifting. Of course, an air-cooling or water-cooling device can be provided on the intermittent position of the conveying spiral disc.

4. Two types of closed type and open type can be designed. The closed type is used for the lifting of powdery materials, which meets the requirements of indoor environmental protection and no dust overflows.

| Model | Diameter of Spiral chute(mm) |

Lifting height (m) |

Speed (rpm) |

Double amplitude (mm) |

Power (kw) |

| DZC-500 | 50 | ≤6m | 960 | 6-8 | 2*0.75 |

| DZC-600 | 600 | ≤7m | 2 X 1.5 | ||

| DZC-800 | 800 | 2 X 2.2 | |||

| DZC-1000 | 1000 | 2 X3.0 | |||

| DZC-1200 | 1200 | 2 X4.5 | |||

| DZC-1500 | 1500 | 2 X5.5 | |||

| DZC-1800 | 1800 | 2 X6.0 |

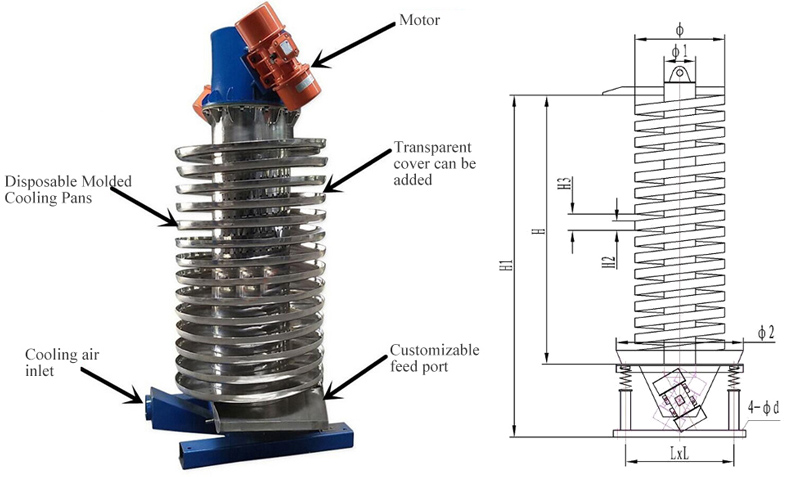

Vertical vibration elevator consists of conveying tower, screw conveying trough, two vibration motors, damping system and chassis.

Conveying tower: It consists of a pipe body and a spiral conveying trough welded around the pipe body. The conveying tower is seated on a shock absorber.

Vibration motor: installed in the lower part of the conveying tower, two vibration motors are installed symmetrically and crosswise.

Shock absorption system: It consists of a base and a shock absorption spring.

| Model | Φ | Φ1 | Φ2 | H | H1 | H2 | H3 | D | Lx8 | Ld×Bd | Φd |

| DZC300 | 300 | 146 | 500 | ~2000 | ~2750 | 40 | 75 | 270 | 680×680 | \ | 11 |

| DZC500 | 500 | 219 | 850 | ~3000 | ~4020 | 50 | 80 | 475 | 1080×1080 | 880×880 | 13 |

| DZC550 | 550 | 245 | 900 | ~35000 | ~4530 | 55 | 85 | 500 | 1100×1100 | 900×900 | 13 |

| DZC600 | 600 | 273 | 950 | ~4000 | ~5150 | 60 | 85 | 525 | 1100×1100 | 900×900 | 15 |

| DZC800 | 800 | 351 | 1200 | ~4500 | ~5650 | 60 | 90 | 650 | 1300×1300 | 1050×1050 | 15 |

| DZC850 | 850 | 402 | 1250 | ~5000 | ~6150 | 65 | 100 | 675 | 1400×1400 | 1150×1150 | 17 |

| DZC900 | 900 | 530 | 1300 | ~6000 | ~7180 | 65 | 110 | 700 | 1600×1600 | 1300×1300 | 17 |

The drive device of the stainless steel vertical vibration elevator is installed at the lower part of the conveying tower. The two vibration motors are installed symmetrically and crosswise. The conveying tower is composed of a pipe body and a spiral conveying groove welded around the pipe body. The conveying tower is seated on the vibration damping device. The vibration damping device consists of a base and a vibration isolation spring.

The feeding height of the feeding tray can be designed according to the situation on site, with an upper-vibration hoist (the motor is installed at the top, and the feed size is low) and a lower-vibration hoist (the lower part of the motor is installed, which is suitable for feeding in the pit).

Address:China,Yanjin county forest park gate to the west 1000 meters north road.