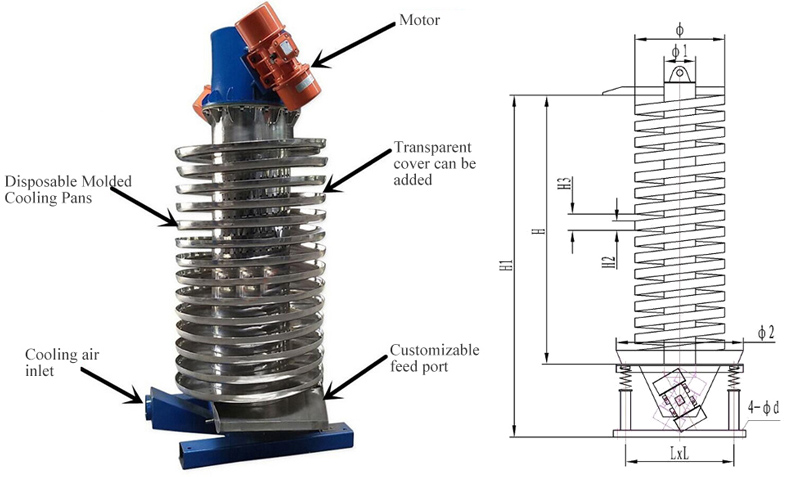

Vertical vibration elevator

Vertical vibration elevator Vertical vibrating screw elevator

Vertical vibrating screw elevator Stainless steel vertical vibration elevator

Stainless steel vertical vibration elevator Cooling vertical vibration elevator

Cooling vertical vibration elevator Vertical vibrating screw conveyor

Vertical vibrating screw conveyor

It is used for vertical lifting of granular, block, and powdery solid materials (low viscosity), and can be used for drying and cooling of materials.

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Conveyor trough diameter: 300-900mm Height: ≤6 meters

Conveying capacity: 3.5 tons/hour

Power: 2* (0.4-3)kw

Frame material: SUS304/Carbon Steel

Speed: Adjsutable Speed

Customization: up-vibration, down-vibration, air-cooled, water-cooled, closed, open, 360-degree feeding, etc.

Application: For conveying and lifting powdery, lumpy and short-fiber materials.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

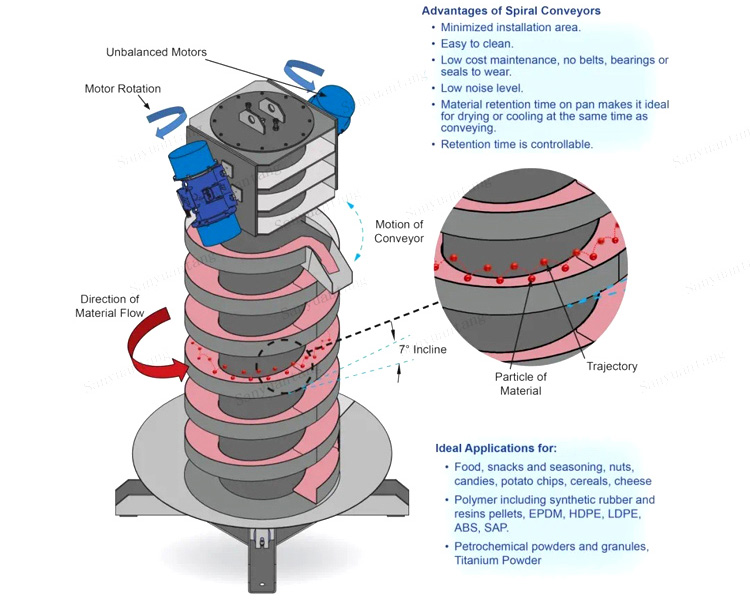

Vertical vibration elevator is also called vertical vibration screw elevator, which generates a certain force through the reverse operation of two vibration motors, so that the product is rotated upwards and conveyed through the spiral conveying trough. The spiral conveying trough is fixed and will not rotate, so for The shape of the product is highly protective. Its lifting and conveying height is not higher than 9 meters from the discharge port to the ground, and the lifting capacity is not higher than about 6 tons. Since the spiral conveying trough is open, it can cool down and dry to a certain extent. It is used for powder and granules. , and small pieces of material are conveyed vertically upwards or downwards. If a heating effect is required, a protective sealing cover can also be added.

Vertical vibration elevator adds cooling auxiliary function on the original basis: water cooling, air cooling or double cooling structure, so as to achieve the required temperature of the material when it is discharged, so as to enter the next link faster, and the failure rate is low.

The vertical vibrating hoist is used to convey and lift powdery, blocky and short fiber materials, and can be used for feeding materials such as filling machines, not only for lifting, but also for drying and cooling during the lifting process, unlike other hoists Compared with the equipment, it is not easy to damage the shape of the material.

In the case of ensuring the stability of the foundation and low failure rate and maintenance rate, this device can also achieve other functions within a certain range:

1. Cooling hoist

Specifically for high-temperature materials that need to be cooled within a certain range during the transportation process, the vertical vibration elevator can add cooling auxiliary functions on the basis: water-cooled, air-cooled or double-cooled structures to achieve the required temperature when the material is discharged , so as to enter the next link faster.

2. Sealed heating

Some users want to heat the interior of the hoist. First, the conveying part must be tightly sealed, and there are certain restrictions on the heating method and temperature. The hot air method requires that the temperature after internal heating should not exceed 180 degrees Celsius. Other heating methods require The part where the heating body itself is in contact with the steel plate does not exceed 120 degrees Celsius.

3. Screening

The equipment itself can realize the function of preliminary sieving, but the mesh value is not less than 2.5mm, and the sieving function can only be used as a preliminary sieving for removing large particles or fine powder, and its sieving accuracy and sieving results are not too much Requirements, the effect of preliminary screening is OK.

When the vertical vibration elevator is working, according to the self-synchronization principle of the dual vibration motors, the vibration motor generates the exciting force, which forces the entire conveying tower body to perform a spatial compound vibration of horizontal circular motion and upward vertical motion, and the materials in the spiral groove are affected by the conveying groove. It makes a circular throwing motion at a uniform speed and moves upward along the conveying trough to complete the upward (or downward) conveying of materials.

Conveying & Drying & Cooling

The elevator can transport powder, block and short-fiber solid materials (except those with stickiness and easy agglomeration) vertically, and can also complete the drying and cooling of materials.

Large delivery volume

The fuselage is stable and can be fed 360 degrees. Compared with other lifting and conveying equipment, it has the advantage of good protection to the shape of the material. The conveying capacity is up to 20 tons/hour, and the height is ≤ 8.5 meters.

Customizable

Vertical vibration elevator is separated into groove type and closed type structure, which can increase the water cooling, air cooling and double cooling structure to achieve cooling effect.

Low cost

The machine has a simple design and structure, is easy to install, use and maintain, consumes less energy, occupies less floor space, and saves investment.

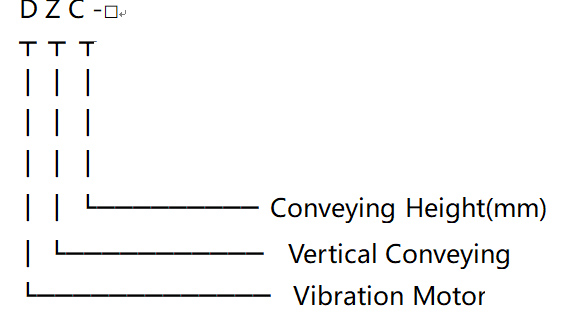

| Model | Diameter of Spiral chute(mm) | Lifting height (m) |

Speed (rpm) |

Double amplitude (mm) |

Power (kw) |

| DZC-500 | 50 | ≤6m | 960 | 6-8 | 2*0.75 |

| DZC-600 | 600 | ≤7m | 2 X 1.5 | ||

| DZC-800 | 800 | 2 X 2.2 | |||

| DZC-1000 | 1000 | 2 X3.0 | |||

| DZC-1200 | 1200 | 2 X4.5 | |||

| DZC-1500 | 1500 | 2 X5.5 | |||

| DZC-1800 | 1800 | 2 X6.0 |

1. The basic type: is an open conveying trough structure, which is used for upward (or downward) conveying of a material without special requirements.

2. The closed type: is a closed conveying trough structure, which is used for upward (or downward) conveying operations where there are dust-proof requirements for materials.

The Vertical vibration elevator consists of a conveying tower, a lifting trough, a vibration motor, a vibration damping system and a base.

Conveying tower: It is composed of a pipe body and a spiral conveying trough welded around the pipe body, and the conveying tower is seated on the vibration damping device.

Vibration motor: Two vibration motors of the same type fixed on the lifting tank are installed at a certain angle across the center line, and can be installed on the upper and lower parts of the conveyor tower.

Shock absorption system: buffer the exciting force generated by the vibration motor.

DZC vertical vibration elevator can add functional configuration:

1. The conveying trough is sealed, or a canvas dust cover is added outside the whole machine.

2. Cooling and upgrading functions: water cooling, air cooling, double cooling.

3. Convey materials vertically downward.

| Model | Φ | Φ1 | Φ2 | H | H1 | H2 | H3 | D | Lx8 | Ld×Bd | Φd |

| DZC300 | 300 | 146 | 500 | ~2000 | ~2750 | 40 | 75 | 270 | 680×680 | \ | 11 |

| DZC500 | 500 | 219 | 850 | ~3000 | ~4020 | 50 | 80 | 475 | 1080×1080 | 880×880 | 13 |

| DZC550 | 550 | 245 | 900 | ~35000 | ~4530 | 55 | 85 | 500 | 1100×1100 | 900×900 | 13 |

| DZC600 | 600 | 273 | 950 | ~4000 | ~5150 | 60 | 85 | 525 | 1100×1100 | 900×900 | 15 |

| DZC800 | 800 | 351 | 1200 | ~4500 | ~5650 | 60 | 90 | 650 | 1300×1300 | 1050×1050 | 15 |

| DZC850 | 850 | 402 | 1250 | ~5000 | ~6150 | 65 | 100 | 675 | 1400×1400 | 1150×1150 | 17 |

| DZC900 | 900 | 530 | 1300 | ~6000 | ~7180 | 65 | 110 | 700 | 1600×1600 | 1300×1300 | 17 |

Vertical vibration elevator can convey and lift powder, lump and short fiber material.

Food industry: powdered sugar, starch, milk powder, egg powder, rice flour, food additives, seasonings, spices, etc.

Chemical industry: fertilizer, washing powder, sodium carbonate, talc, dye, rubber, PVC resin, pigment, cosmetics, paint, traditional Chinese medicine powder, fiber, etc.

Metal and metallurgical industry: copper powder, nickel powder, aluminum powder, copper granules, ore alloy powder, welding powder, battery material, grinding powder, fireproof material, etc.

Dahan vertical vibration elevator has 12 years of production experience, complete models, reasonable price, 1 year warranty, fast customization, and free model selection to provide drawing parameters.

Conveying alumina

The calcined alumina cannot be screened directly because its temperature is too high. The vertical vibration elevator can be used to cool the alumina by wind during the transportation or lifting process, so that the temperature can be reduced to 50-100 degrees, and then screened. The alumina powder at this temperature is relatively dry, which is more conducive to screening.

Conveying chicken bouillon

The finished MSG, Chicken Essence and other foods have a certain temperature after processing, and need to be cooled before being bagged. The vertical vibration elevator can be used to load the material to dissipate heat easily, and it can also be directly transported to the bag filling machine.

Conveying pills

The finished pills are viscous to a certain extent, and they are easy to agglomerate due to the wet weather during transportation. The conveying effect of the belt conveyor is not good, and the cost of the bucket elevator is high. If our conveying volume is not too large, the vertical vibrating elevator is a good choice.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.