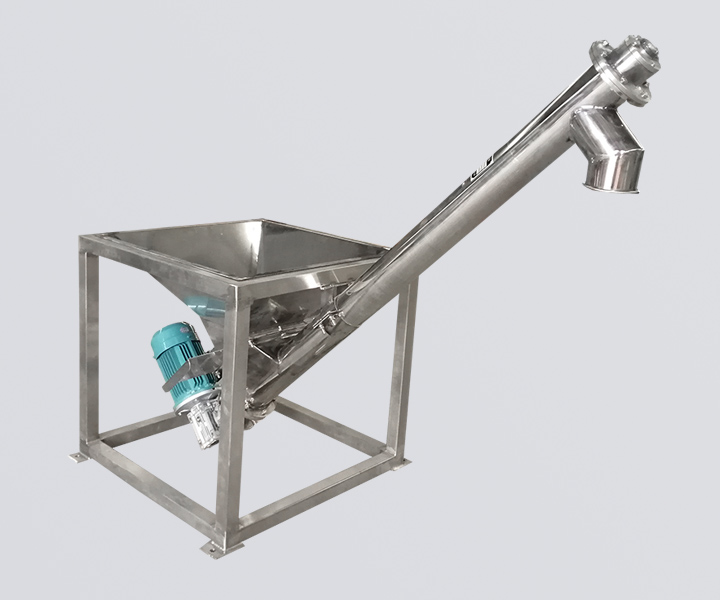

Screw feeder hopper

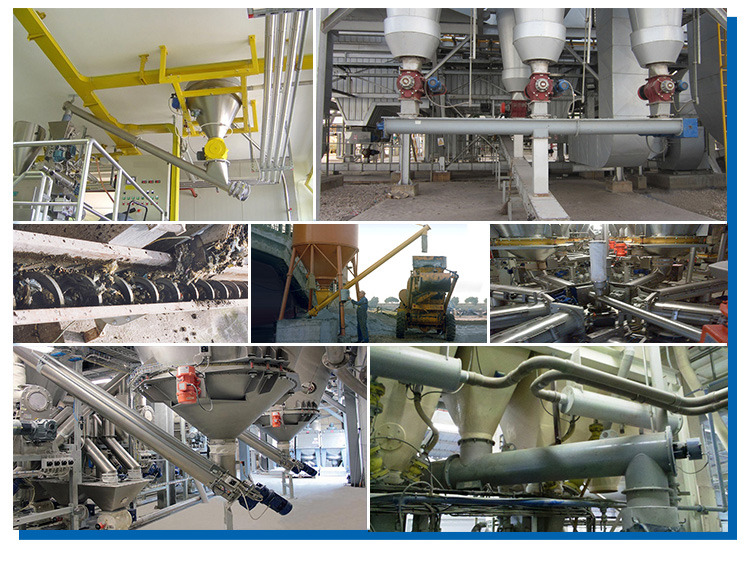

Screw feeder hopper Movable screw feeder hopper

Movable screw feeder hopper Carbon steel screw feeder hopper

Carbon steel screw feeder hopper Vertical screw feeder hopper

Vertical screw feeder hopper Twin screw feeder hopper

Twin screw feeder hopper

Can be used with various filling machines and high-speed mixers for powder and granular material transportation

![]()

![]()

Price:$565.00 - $6,282.00/ Set

Consult now and enjoy a 10% discou

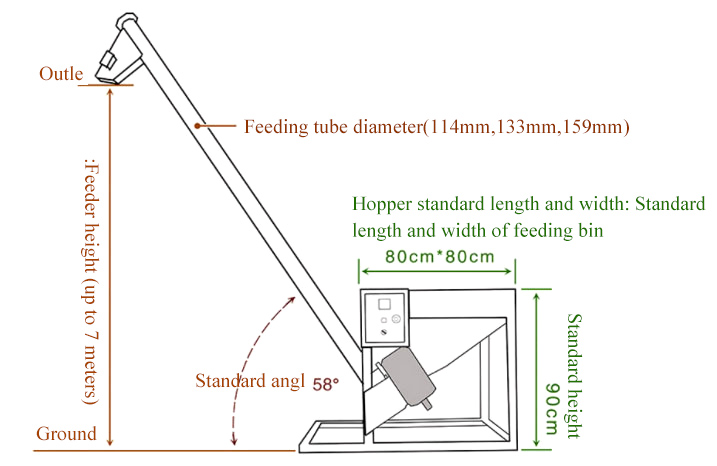

Hopper volume:80-300 kg

Conveying capacity:500-3000KG/hour

Conveying height: ≤ 8 meters (special requirements can be customized)

Feeding speed: 1 cubic meter/hour

Power supply: 380V/220V

Power: 1.5KW/2.2KW/5.5KW

Weight: 80KG

Application: flour, soybeans, feed, plastic particles, coal powder, muck, cement and other powders and granular materials

Commitment:

Screw feeder hopper is a uniform feeding equipment designed and produced by modifying the principle of screw conveyor. This equipment is easy to feed non-sticky powdery, granular and small particle materials evenly from the silo and other storage equipment. The material receiving equipment has the functions of conveying, sealing, homogenizing and stirring at the same time. It is a common equipment in cement raw material homogenization and silo sealing feeding. The feeding size is less than 5mm. According to customer requirements), to ensure that the raw materials are completely pollution-free during the conveying process. The conveying pipeline adopts a closed design, which can effectively prevent dust and effectively isolate materials with high hygiene requirements or strong odors. It has the characteristics of uniform feeding, good sealing, and no dust.

Dahan screw feeder hopper can be customized with different diameters, different lengths, and different inclinations according to user requirements, and can be equipped with a speed-regulating motor to continuously adjust the speed to achieve the purpose of quantitative feeding.

Carbon Steel Screw Feeder Hopper

It is used in industries where hygiene requirements are not very strict, with low cost, large conveying capacity, good heat insulation effect, no cooling device and low power consumption.

Stainless Steel Screw Feeder Hopper

It is mostly used in industries such as food and medicine that have high requirements for a hygienic environment. It is resistant to acid, corrosion, wear, and rust. It is also more convenient to clean up after use.

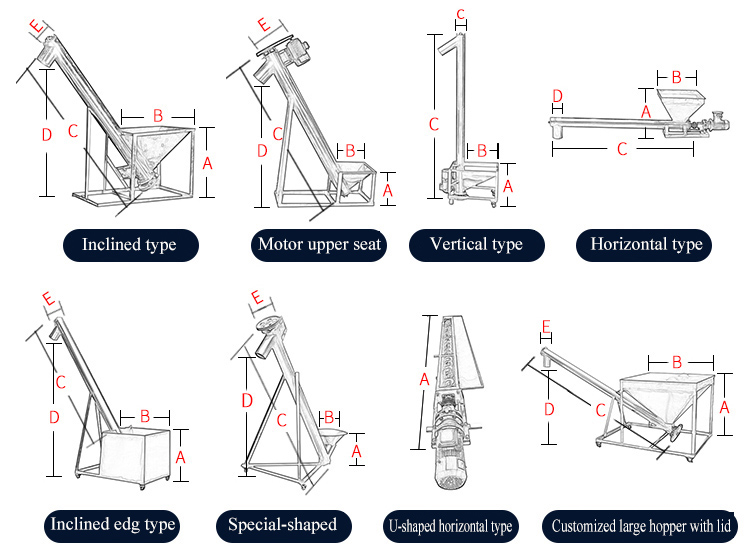

Horizontal Screw Feeder Hopper

It is used for continuous and uniform conveying of loose materials horizontally or slightly inclined (below 20º), and the conveying distance is generally not more than 70 meters.

Inclined Screw Feeder Hopper

It is used for conveying materials within a range of 60°, and the conveying length can reach 60 meters. It can convey and lift products at the same time, and can directly and automatically convey powder or granular plastic raw materials to silos or other equipment.

Vertical Screw Feeder Hopper

90° vertical upward conveying of materials, the speed is higher than that of ordinary screw conveyors, the lifting height is generally not more than 8 meters, and the floor area is small.

Screw feeder hopper is mainly composed of feed inlet, screw blade, barrel, driving device, discharge outlet and other parts. During operation, after the material is transported to the shell of the screw feeder through the feed port, the material is subjected to the centrifugal force and the friction force of the pipe wall in the internal spiral groove, and rotates together with the spiral blade, and moves along the spiral spiral under the action of gravity. The trough slides down, so that the material is continuously pushed forward and conveyed, and finally discharged evenly from the discharge port.

There are two types of screw feeder hoppers: single tube and double tube. It consists of unloading device, screw shaft, feeding device, transmission device and other components.

Vibration motor: The feeding motor and the vibration motor can be switched separately to control the vibration amplitude. The system has a time relay. Each time the time is set according to the set amount, the feeding amount is controlled.

Hopper: The design of the hopper should consider reducing the pressure of the feeding screw, and if necessary, increase the decompression mechanism to improve the feeding accuracy. Round or square hopper can be selected, which is convenient for feeding. It can be used alone or directly connected to its supporting equipment.

Material box size: 900mm×700mm×950mm

Storage box: stainless steel

Loading capacity: 250kg

Screw feeder hopper is used to evenly feed non-sticky powdery, granular and small granular materials from storage equipment such as silos to receiving equipment, usually in large quantities from hoppers, silos or bins, and is widely used in conveying flour processing industry materials (bran, flour, etc.), feed industry (pet feed, fish feed) and bridging materials (such as sawdust, soybeans, etc.), according to the requirements of different industries, also provide single-screw and twin-screw models.

Conveying grain

Conveying wheat bran

Uniform feeding, adjustable feeding amount

The feeding is uniform, and the material is not easy to be blocked. The feeding speed can also be controlled by installing a frequency conversion motor. There is a time relay in the system, and the feeding time can be set according to each feeding amount.

Reduce costs

If multiple mixers use the same material, only one screw feeder hopper can feed multiple mixers at the same time, eliminating the need for manual feeding and reducing labor costs.

Hygienic operation

The storage box and conveying pipe are made of stainless steel, which ensures that the raw materials are completely free from contamination during the conveying process.

Flexible layout

It can be installed horizontally, can also be adapted to angular working conditions, and can even be conveyed vertically.

Sealed delivery

Good sealing, avoids dust pollution to the environment, and improves working conditions at the same time.

Small footprint

It can be directly connected and fixed with its supporting equipment, no foundation is required, and the workshop space can be fully utilized.

| Model | Spiral diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Conveying capacity (m³/h) |

Rotating speed (r/min) |

Conveying capacity (m³/h) |

Rotating speed (r/min) |

Conveying capacity (m³/h) |

Rotating speed (r/min) |

Conveying capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Shaftless screw feeder hopper | Features: No central shaft design is suitable for conveying viscous and easy-to-wind materials, and the conveying flow is larger |

| Stainless steel screw feeder hopper | Features: Stainless steel material is high temperature resistant and corrosion resistant, in line with food and medical delivery standards |

| Double screw feeder hopper | Features: The material can be mixed and stirred during the conveying process, and the feeding amount is 1.5-2 times that of the single shaft |

| Water-cooled screw feeder hopper | Features: Water cooling system can reduce 750°C high-temperature materials to 50°C |

| Mobile screw feeder hopper | Features: Brakeable universal wheels are installed at the bottom to flexibly adapt to changes in the production site |

In addition to the above parameters, if there are other requirements for the machine, such as: the machine needs to be made of stainless steel 304, or needs two delivery ports, or needs universal wheels, or needs a feeding pipe at the bottom, or needs a frequency converter, Or if you need an anti-blocking switch, or other special designs, please contact us.

Xinxiang Dahan has 12 years of experience in the production of screw feeder hopper. The screw feeder hopper has a complete range of models and can provide free selection and drawing design. It has a variety of lathes, milling machines, installation workshops, spraying workshops, warehouses and other processing workshops, as well as various cutting machines, Bending machine and polishing machine processing equipment provide one-stop service from design, drawing, processing, assembly, painting, quality inspection, test machine, packaging and delivery, etc., providing 12-month quality warranty and lifetime maintenance services.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.