It is used to screen various solid and powdery materials to achieve particle size separation and material classification.

![]()

![]()

![]()

Price:$580.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Applications: Suitable for screening various dry powders and granules with a particle size of 0.074-5mm, such as plastic granules, chemical fertilizers, activated carbon, quartz sand, wheat bran, etc.

Commitment:

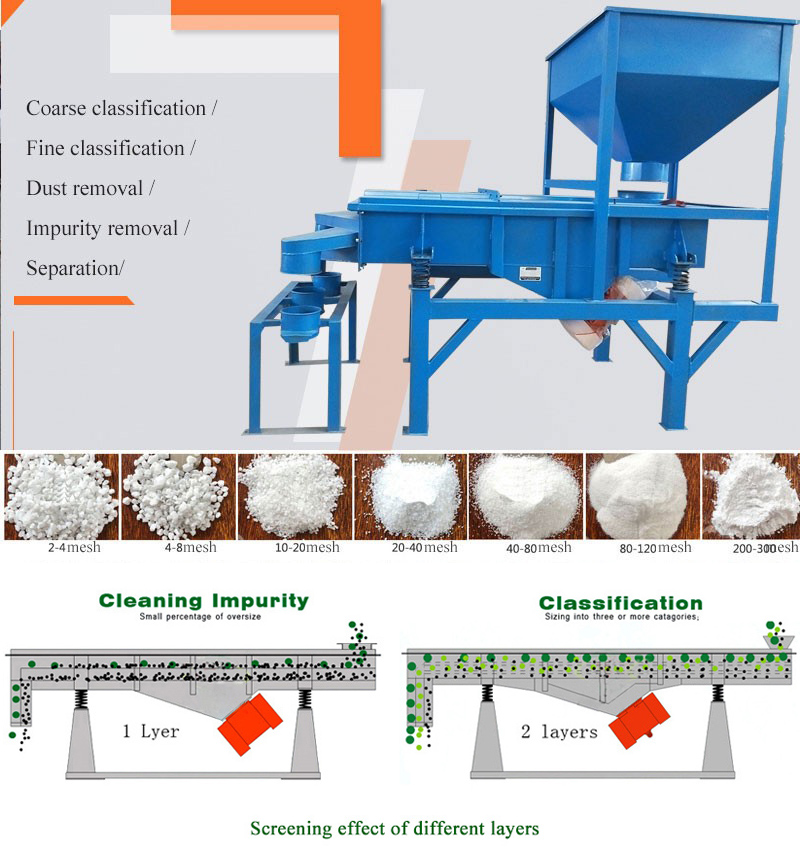

Screen machine industries is a common industrial screening equipment. It screens and grades materials through linear vibration motion. It is widely used in mining, metallurgy, chemical industry, building materials, food processing and other industries for screening various solids. and powdery materials. It can realize functions such as particle size separation, material classification and impurity removal.

The screen machine industries has single-layer, double-layer and multi-layer screens. Seven different classifications can be completed in one operation. Screen sizes range from 3/8 inch (10 mm) to 400 mesh (38 microns), 500 mm to 1,500 mesh. Available in millimeters wide and 1,500 to 4,000mm long screening areas, allowing processing capacities of up to 20 tonnes/hour, can be customized to customer requirements.

Screen machine industries is a common material handling equipment that is widely used in various industries and fields. The following are several main uses of industrial screens:

1. Screening and classification: It is used to screen and classify materials according to particle size, size or other specific requirements. It is able to separate raw materials into different granularity levels to meet product quality and specification requirements. Common applications include ore screening, construction material screening, granular material classification, etc.

2. Removal of impurities: Impurities, solid particles or foreign matter in the material can be separated and removed through the settings of the sieve holes or screen mesh. This plays an important role in ensuring product quality, purifying raw materials and preventing equipment clogging.

3. Pretreatment before crushing: In some material processing processes, screen machine industries can be used for pretreatment before crushing. By screening and classifying raw materials, large pieces of material, materials that do not meet the requirements can be removed, and the load on the crushing equipment can be reduced. This helps improve crushing efficiency and equipment life.

Linear vibrating screen

Designed for large output, it is suitable for safe screening, classification, and dust removal of powders and granules. It can choose from 1 to 6 layers and can complete 7 different classifications in one operation.

Application materials: screening of medium-dry powdery materials such as frozen dumplings, sand and gravel, silicon carbide, rapeseed, peanut shells, almonds, limestone, etc.

Air-cooled Linear Vibrating Screen

It is an industrial screening equipment that uses vibration force to screen and classify materials. It uses an air-cooling system to cool the screen through airflow, effectively controlling the screen temperature to avoid material adhesion and clogging, thereby improving screening efficiency and equipment life.

Application materials: Mainly used in material handling occasions that require cooling and dust removal. It is suitable for screening high-temperature materials such as fly ash, cement, cinder, lime powder, and washing powder.

Pharmaceutical Linear Vibrating Screen

Screening equipment specially designed for the pharmaceutical industry for fine screening and classification of pharmaceutical raw materials, intermediates and finished products. It uses linear vibration motion to effectively separate and classify pharmaceutical materials through the screen to ensure that the products meet quality requirements.

Application materials: Mainly used in the pharmaceutical industry for screening and grading pharmaceutical materials such as pharmaceutical powders, tablets, and pharmaceuticals.

Multilayer Linear Vibrating Screen

It has a multi-layer screen structure. It uses linear vibration motion to screen and classify materials in layers to achieve a finer screening effect. Multi-layer linear vibrating screens usually have multiple screen layers, and each screen layer can be set with different mesh sizes as needed to meet the screening requirements of materials with different particle sizes.

Application materials: Suitable for grading ore, ore, coal, coke, quartz sand, cement, coffee beans, plastic particles, etc. of different particle sizes.

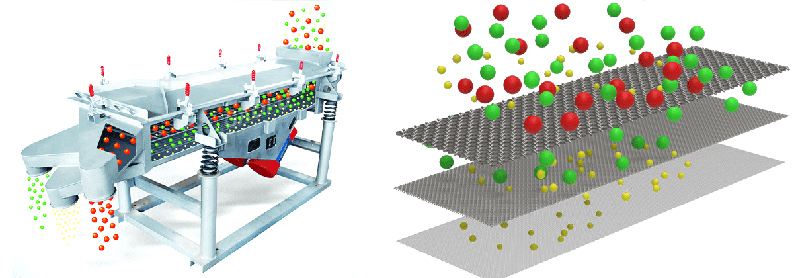

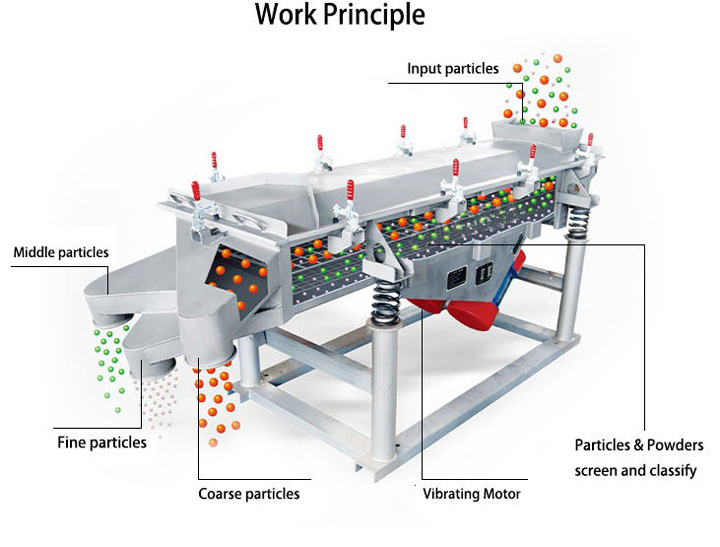

The vibration force generated by the vibration motor causes the screen surface to vibrate linearly, causing the granular materials to jump on the screen surface, thereby achieving screening. Materials enter the screen surface from the feed port, pass through the screen holes or are blocked according to the size of the particles, and are divided into multiple materials with different particle sizes. Screen machine achieves classification and screening of materials through different screen hole sizes and vibration parameters.

Efficient screening

Using linear vibration motion, materials can be screened quickly and continuously on the screen. It has a large screening area and high screening efficiency, which can quickly separate particles that meet the requirements and improve production efficiency.

Accurate classification

It has a multi-layer screen structure and can set different screen hole sizes according to the particle size requirements of the materials. In this way, materials can be accurately classified and particles of different sizes can be screened in layers to meet different application needs.

Adjustable amplitude and frequency

The amplitude and vibration frequency can be adjusted according to material characteristics and screening requirements. By adjusting the amplitude and vibration frequency, the screening effect can be optimized, adapted to the screening needs of different materials, and the screening accuracy and efficiency improved.

Low energy consumption and quiet operation

The machine uses dual vibration motors as the excitation source, which has the characteristics of low energy consumption and high efficiency. At the same time, its structural design can effectively reduce noise and vibration transmission, achieving relatively silent operation.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Screen machine industries can be customized according to different application requirements and material characteristics. Here are some common types of customization:

| Name | Image | Features |

| Mobile screen machine industries |  |

It is suitable for high-temperature materials and can be screened after effectively reducing the temperature of the materials. |

| Adjustable screen machine industries |  |

Adjust the angle and height of screen machine industries according to the material screening process. |

| Hanging screen machine industries |  |

Screening equipment that can be installed in the air saves space at the screening site |

| Silo type screen machine industries |  |

Equipped with a feeding bin, the feeding speed can be controlled by adjusting the feeding bin plug-in. |

Screen machine industries are widely used in the following industries:

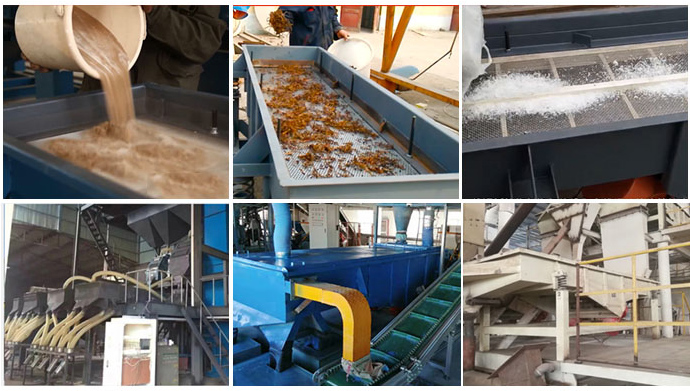

Mining and Mining Industry: Used for screening, grading and removing impurities from ores. It can be used to screen metal ores, coal, limestone, iron ore, etc.

Metallurgical industry: used for preliminary screening of ores, screening of roasted ores and recovery of slag. It is also used for screening bauxite, manganese ore, copper slag and other materials.

Building materials industry: used for screening and grading materials such as stone, sand, cement and concrete.

Chemical industry: used for screening and classifying chemical raw materials, pigments, coatings, rubber, plastics and other chemical products.

Food and beverage industry: used for screening and grading of grain, food additives, condiments, milk powder, juice and other products.

Pharmaceutical industry: used for screening medicinal materials, screening intermediates and grading medicinal powders.

Recycling industry: directly used for screening and classifying waste and recycled materials, such as waste plastics, waste paper, scrap metal, etc.

| Material | Proportion | Mesh | Model | Method | Processing Capacity Kg/h |

| Millet | 0.15 | 250 mesh | DZSF-515-2s | Dry | 600 |

| Quartz Sand | 1.6 | 70 mesh | DZSF-1540-3s | Wet | 30000 |

| Raisin | 0.83 | 60 mesh | DZSF-520-1s | Wet | 6000 |

| Sunflower Seeds | 0.04 | 80 mesh | DZSF-525-1s | Dry | 7100 |

| Plastic Particles | 0.95 | 3 mm | DZSF-515-2s | Dry | 500 |

| Flour | 0.6 | 24 mesh | DH-515-3S | Dry | 1500 |

| Iron ore Powder | 2.3 | 150 mesh | DZSF-1020-3s | Dry | 10000 |

| Slag | 4 | 5 mm | DZSF-1020-1s | Dry | 10000 |

| Sawdust | 0.2 | 80 mesh | DZSF-1030-3S | Dry | 18000 |

| Emery | 4 | 60 mesh | DZSF-515-1S | Dry | 300 |

| Wood Flour | 0.4 | 120 mesh | DZSF-1036-4s | Wet | 2000 |

| Activated Carbon | 0.8 | 36 mesh | DZSF-515-1s | Dry | 500 |

Xinxiang Dahan Vibration Machinery Co., Ltd. has a factory area of 10,000 square meters. It has been established for 12 years and has rich production experience. Our company has passed ISO and CE certification. The product quality is good. If the machine has performance problems within 7 days of sale, the user You can choose free repair, replacement or return.

Screen machine industries model models include DZSF-520, DZSF-525, DZSF-530, DZSF-1020, DZSF-1025, DZSF-1030, etc. Carbon steel and stainless steel materials can be selected according to the characteristics of the screening materials, and according to the screening purpose To choose 1~6 layers of screen mesh, if you have special requirements, we can also customize different configurations and designs according to the user's process needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.