Industrial screener is a type of key equipment that are widely used in material screening and classification processes in various industries. Different types of industrial screener can meet the screening needs of different materials according to their working principles and applicable fields, and improve production efficiency and product quality. What are the different types of industrial screeners? This article will review the different types of industrial screener and their areas of application in various industries.

Ultrasonic screeners are equipment that uses ultrasonic vibration technology for screening. They are suitable for screening fine-grained materials, especially sticky and easy-to-clog materials. It can be widely used in food, chemical, pharmaceutical and other industries. Its working principle is to apply high-frequency vibration on the screen through an ultrasonic vibration source, so that materials can quickly pass through the screen holes, effectively preventing adhesion and clogging.

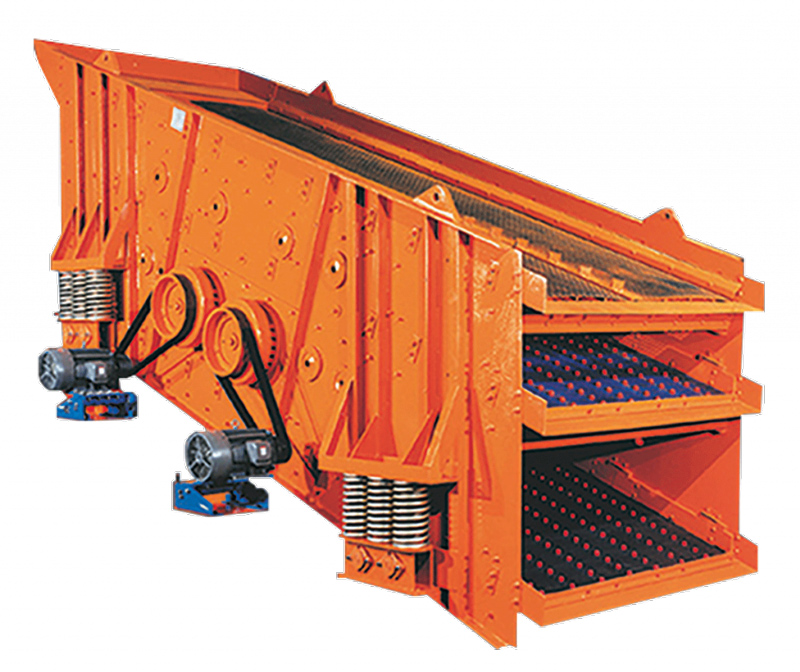

Vibrating screeners are one of the most common types of industrial screens. It uses vibration force to screen materials on the screen. Vibrating screeners are suitable for screening powdery and granular materials and are widely used in ores, building materials, chemicals and other industries. Its working principle is to use the vibration force generated by the vibration motor to make the materials in the screen box move quickly on the screen to achieve material separation.

Cyclone screeners is a device that uses centrifugal force and air flow to screen materials. It separates materials through rotating airflow and is suitable for screening materials with a lot of dust. Cyclone screening machines are widely used in fly ash, cement, granular materials and other industries. Its working principle is that materials enter the cyclone separator through the feeding device. Under the action of centrifugal force and air flow, the finer materials are taken away, while the coarser materials are left on the screen.

Inclined screeners is a specially designed screening equipment with an inclined screen surface. Incline screeners is suitable for screening wet materials and high-viscosity materials, such as ore leachate, ceramic slurry, etc. Its working principle is that materials are screened on an inclined screen surface, and the material is separated by the tilt angle and vibration force of the screen surface.

Linear screeners use linear vibration for screening. It is suitable for fine-grained materials and high-precision screening, such as sand, coal, chemical raw materials, etc. Linear screeners have the advantages of high screening efficiency and large processing capacity. Its working principle is that materials are screened on the linear screeners surface, and materials of different particle sizes are separated by adjusting the vibration force and screen surface inclination angle.

The rotary screener is a device that uses a rotating screen drum for screening. It is suitable for screening wet materials and sticky materials, such as coal slime, limestone, paper slurry, etc. The rotary screening machine has the characteristics of large processing capacity and strong adaptability. Its working principle is that materials enter the rotating screen cylinder through the feed port, and the materials are separated through the action of the rotating screen cylinder and screen holes.

These different types of industrial screeners play an important role in different industries and application fields. Through different working principles and structural designs, they meet the screening needs of different materials. The above is a brief introduction to the types of industrial screens. Each type of industrial screens is widely used and has various models. If you want to know more about other types of industrial screens, you can chat with us directly online. Your consultation is always welcome!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.