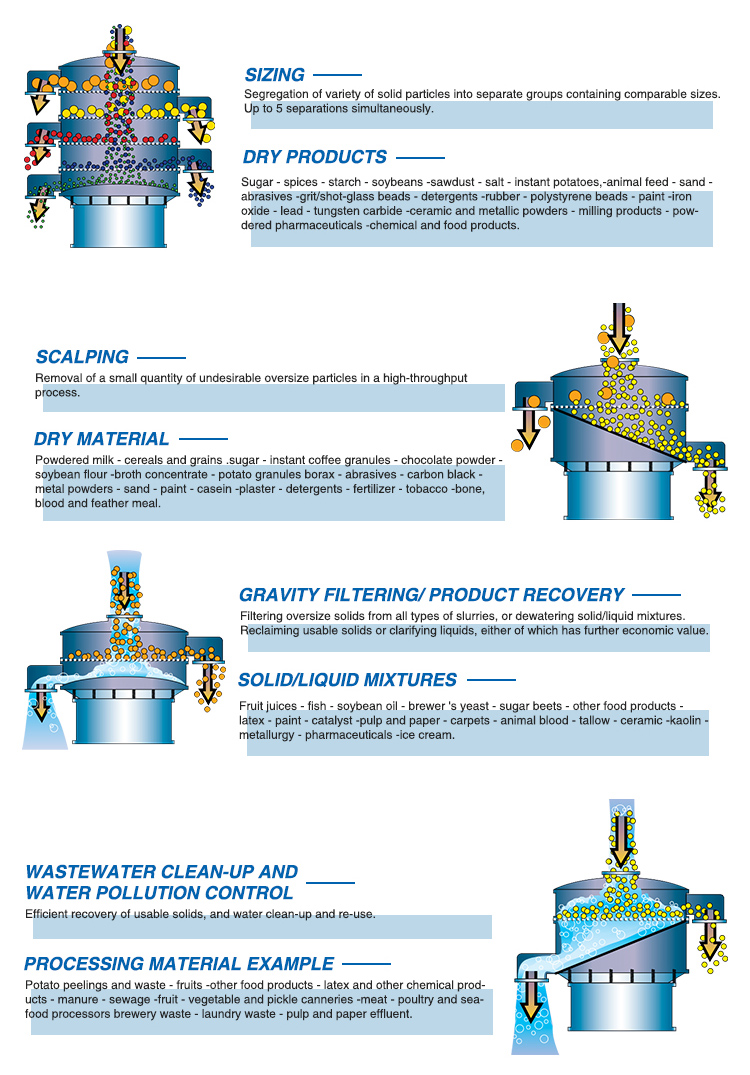

Industrial screener is an important equipment widely used in various industrial fields. Its main function is to screen and classify materials to meet different process requirements and product quality standards. The industrial screener separates raw materials according to different particle sizes through vibration or rotational motion to achieve an efficient and precise screening process. The following will introduce in detail how the industrial screener works.

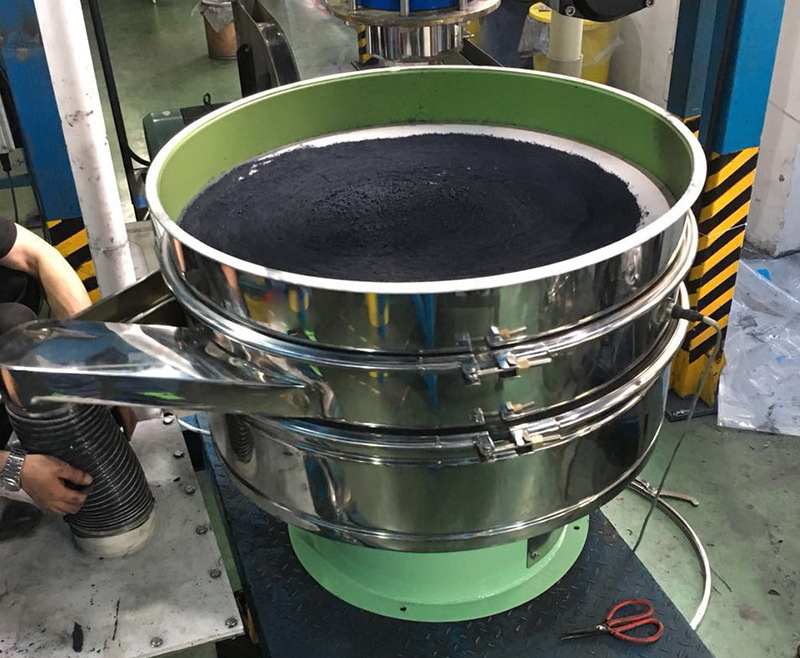

The working principle of the industrial screen is based on the vibration or rotational movement of the material. It usually consists of a screen box, a screen, a driving device and a supporting device. The material enters the screen box through the feed port. Under the action of the screen, it is subject to vibration or rotational force, causing the material to move relative to the screen. Materials with smaller particle sizes pass through the sieve holes, while materials with larger particle sizes are blocked on the screen, thereby achieving material separation and classification.

(1) Material feeding: Raw materials enter the screen box through the feeding port and enter the screening area.

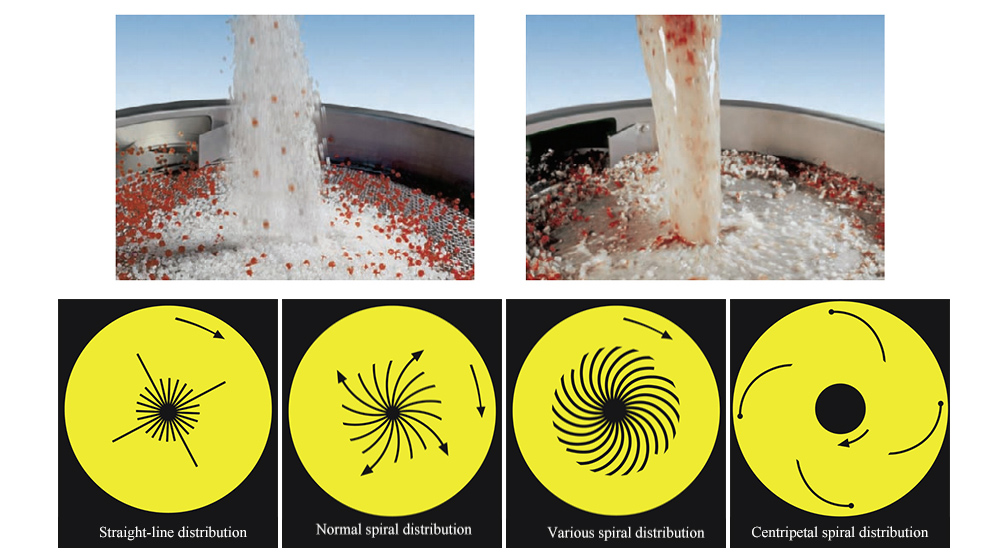

(2) Screen vibration or rotation: The industrial screener generates vibration or rotational force through the driving device, causing the screen box and screen to produce corresponding vibration or rotational motion. Vibrating screening machines use vibration force to screen materials on the screen, while rotary screening machines separate materials through rotational motion.

(3) Material screening: During the screening process, the materials move relative to each other on the screen. Materials with smaller particle sizes can pass through the screen holes, while materials with larger particle sizes are blocked on the screen. Through continuous vibration or rotation, the material gradually moves downward on the screen until it passes through the screen holes or is blocked on the screen.

(4) Separation and classification: Through the screening process, the industrial screener separates and classifies the materials according to different particle sizes. Materials with smaller particle sizes pass through the sieve holes and are collected at the discharge port below to form fine-grained products. Materials with larger particle sizes are blocked on the screen and separated through different screen holes to form coarse-grained products.

(5) Discharge and collection: The separated materials are discharged and collected through the discharge port. Fine-grained products and coarse-grained products are discharged from different discharge ports respectively, and are collected and subsequently processed as needed.

Through the above working process, the industrial screener can achieve efficient screening and classification of materials. By adjusting the mesh size and screening parameters of the screen, the accuracy and effect of the screening process can be controlled to meet different process requirements and product quality standards.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.