Used for vertical conveying of powdery, granular and small block materials.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: Used in grain, feed, chemical industry, plastics, construction and other industries.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Rice bucket elevator is a type of vertical conveyor system specifically designed for handling rice and other similar grains. It is commonly used in rice mills, grain storage facilities, and processing plants to efficiently move bulk quantities of rice from one level to another.

The primary function of a rice bucket elevator is to lift and transport rice vertically between different floors or levels within a facility. It consists of a series of buckets attached to a continuous belt or chain. These buckets are specifically designed to scoop up rice as they move along the elevator's vertical or inclined path.

The rice bucket elevator is widely used in the rice industry. Here are some common applications where rice bucket elevators are used:

1. Rice milling: transporting rice from one stage to another, such as from cleaning to husking, or from husking to polishing.

2. Grain storage facilities: used to move rice from the ground to a higher level, enabling efficient storage and retrieval. They help maximize storage capacity by utilizing vertical space.

3. Rice processing plant: used to transport rice between different processing units. For example, they can move rice from a parboiling unit to a drying unit or from a drying unit to a milling unit.

Efficient and Reliable Transportation

A rice bucket elevator provides efficient and reliable transportation of rice from one level to another. It can handle large volumes of rice and ensure a smooth flow of material, reducing the need for manual labor and improving overall productivity.

Minimal Loss and Spillage

The design of the buckets in a rice bucket elevator minimizes loss and spillage of rice during transportation. The buckets are specifically designed to scoop up the rice and prevent it from falling out, ensuring minimal waste and maximizing the yield of processed rice.

Space Optimization

Rice bucket elevators are vertical conveyor systems, which help optimize space utilization in a rice mill or processing facility. They can be installed in a compact manner, taking advantage of vertical space and allowing for efficient material handling without occupying a large floor area.

Improved Hygiene and Food Safety

Rice bucket elevators can be designed with features that promote hygiene and food safety. They can be constructed using materials that are easy to clean, preventing contamination of the rice during transportation. Additionally, they can be equipped with covers or enclosures to protect the rice from external contaminants.

Labor Savings

By automating the process of rice transportation, a bucket elevator reduces the reliance on manual labor. This not only saves labor costs but also minimizes the physical strain on workers, leading to improved safety and employee well-being.

Enhanced Product Quality

A rice bucket elevator ensures gentle handling of rice grains during transportation, minimizing damage and breakage. This helps preserve the quality, appearance, and integrity of the rice, resulting in higher-quality final products.

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

Rice bucket elevator can solve the following problems:

1. Vertical transportation problem of rice: The rice bucket elevator can lift rice from one processing stage to another without manual transportation, which improves efficiency.

2. Rice crushing problem: The rice bucket elevator can adopt low-speed operation and special hopper design to minimize the crushing of rice during transportation.

3. The problem of high labor intensity: Rice bucket elevators can replace manual handling and reduce labor intensity.

4. The problem of low production efficiency: The rice bucket elevator can improve the efficiency of rice processing and increase production volume.

5. Environmental pollution issues: The rice bucket elevator can be operated in a closed manner to minimize dust and leakage and reduce environmental pollution.

Rice bucket elevators can be customized in several ways to suit specific requirements and facility constraints. Here are some common customization options:

1. Bucket Size and Shape: The size and shape of the buckets can be cuscomed base on the specification characteristics of the rice bebing hardled, Such As Grain size And density. Larger Buckets Can Accommodate Higher Capacities, While Smaller Buckets Are Suitable for Handling Finer rice varieties.

2.Belt or Chain Speed: The speed at which the belt or chain of the rice bucket elevator moves can be adjusted to meet the desired conveying rate. This customization allows for optimal throughput and ensures efficient handling without causing damage to the rice.

3.Discharge Height and Orientation: The discharge height of the rice bucket elevator can be customized to match the specific requirements of the facility. It can be designed to discharge rice at a particular height or angle to align with downstream equipment, storage bins, or processing units.

4.Control Systems and Automation: Rice bucket elevators can be integrated with advanced control systems and automation technologies. This customization allows for precise control over the conveying process, including start/stop functions, speed adjustments, and monitoring of operation al parameters. Automation can also enable seamless integration with other equipment or production lines.

5.Material and Surface Finish: The choice of materials and surface finishes can be customized to meet specific requirements. For example, stainless steel construction may be preferred for applications where hygiene and corrosion resistance are crucial, such as in food processing f abilities. The surface Finish can be selected to minimize the risk of product contamination or to facilitate easy cleaning.

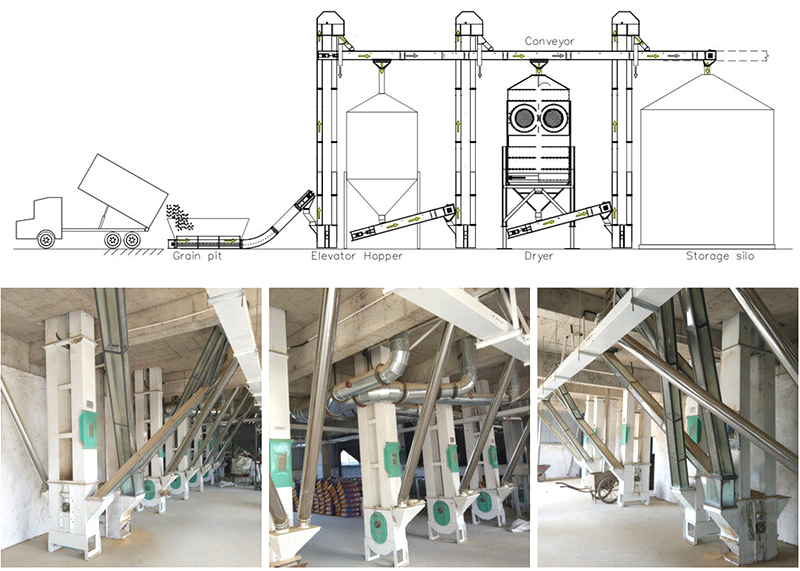

1. Rice bucket elevator: As a core component, rice bucket elevator is used to transport rice from one level to another. It can lift rice to the required position efficiently and reliably, reducing manual handling and improving production efficiency.

2. Rice mill: Rice mill is used to hull and grind rice into rice. It can process raw rice into finished rice through husking, grinding and other process steps. Among solutions, rice bucket elevators can be used to transport processed rice from the discharge port of the rice mill to the next processing stage or storage facility.

3. Cleaning and screening equipment: Cleaning and screening are usually required during rice processing to remove impurities and incomplete grains. This may include cleaning equipment, stone removers, magnetic separators, color sorters, etc. These devices can be connected to rice bucket elevators to achieve a continuous rice processing process.

4. Storage facilities: Processed rice needs to be stored for subsequent packaging and sales. Solutions may include large storage silos or tanks for temporary storage of rice. Rice bucket elevators can be used to transport rice from the discharge port of rice mills or cleaning equipment to storage facilities.

5. Packaging equipment: Packaging rice is the last step in rice processing. Solutions may include automatic packaging machines or weighing packaging machines for packaging rice into different sizes of bagged or bulk products. The rice bucket elevator can be connected to the packaging equipment to transport the processed rice from the storage facility or discharge port to the packaging equipment.

The following are two different cases showing the application of rice bucket elevators to different customers:

1. Large rice processing factory: A large rice processing factory uses rice bucket elevators to manage its production process. The plant has multiple rice mills, cleaning equipment and storage facilities. Rice bucket elevators are installed between different floors to transport processed rice from the rice mill to cleaning equipment for screening and cleaning, and then transport the processed rice to storage facilities. This solution improves production efficiency, reduces manual handling, and ensures rice quality and integrity.

2. Small rice processing workshop in rural area: A small rice processing workshop in rural area uses rice bucket elevator to improve its processing process. In the past, they mainly relied on manual handling and simple mechanical equipment to lift and transport rice. With the introduction of rice bucket elevators, they are now able to transport rice from the rice mill to cleaning equipment and storage facilities more efficiently. This solution helped them save labor costs, increase productivity, and improve the working environment.

Xinxiang Dahan is a well-known manufacturer specializing in the production of rice bucket elevators. The manufacturer has advanced production equipment and technical teams, with a variety of product types, reliable quality and superior performance. Xinxiang Dahan's rice bucket elevator is reasonably designed and easy to operate, and is widely used in the grain processing industry. Dahan manufacturers pay attention to product quality and customer needs, provide customized solutions, and are well received by customers. Xinxiang Dahan is committed to providing customers with efficient and stable rice bucket elevators to help the development of the grain processing industry.

Dahan conveying equipment manufacturer, we have many years of development history. Our rice bucket elevator is made of high-quality materials and advanced technology to ensure the quality of the equipment. It is widely praised for its stable, reliable, efficient and energy-saving characteristics. In addition, the company also provides customizable solutions, customized production according to the specific needs of customers and site conditions. Whether it is material type, conveying height or production capacity, the company can provide professional customization solutions to meet the diverse needs of customers. The price is generally between $800.00-$3,000.00/Set. Due to different prices for different models, if you need it, please contact us. We will recommend a suitable model for you and quote according to your situation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.