For checking particle size and removing foreign matter prior to bagging or processing

![]()

![]()

![]()

Price:$580.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

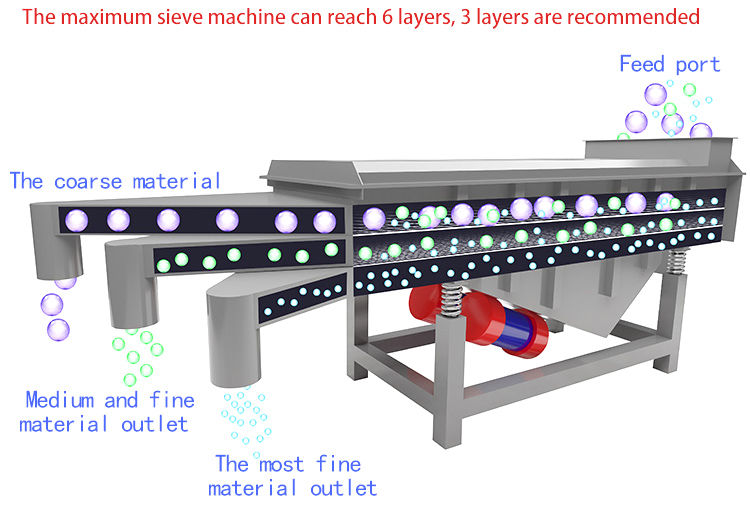

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Applications: Screening and grading, removal of oversized or foreign objects, undersized or debris, or dust removal from powders and granules before packaging finished products perform many functions together.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Rectangular screen, also known as rectangular vibrating screen, its shape is rectangular, and the product moves in a straight line, suitable for linear screening systems for light or heavy applications, suitable for safe screening, grading, and dust removal of powders and granules, and can be installed with multi-layer screens , divide the product into 2-7 different sizes.

Rectangular screen is available in single layer, double layer and multi layer screen, can complete 7 different classifications in one operation, mesh size ranges from 3/8 inch (10mm) to 400 mesh (38 microns), available in 500mm to 1,500mm wide And 1,500 to 4,000mm long screening area, allowing up to 20 t/h processing capacity, can be customized according to customer requirements.

Rectangular screen is very suitable for eliminating impurities in powder or granules, separation of different specifications of the same product, the range of screen openings is from 3/8 inch (10 mm) to 400 mesh (38 microns), widely used in abrasive industry , chemical industry, food industry, pharmaceutical industry, fertilizer industry, plastic granules and other industries.

Rectangular vibrating screens have many different uses, including:

①Removal of fine particles

②Separate oversize and agglomerates and divide them into 2-7 different grades.

③ Medium and short distance transportation

Multilayer Rectangular Vibrating Screen

Installed with multi-layer screens, such as double-layer, three-layer, four-layer, five-layer, six-layer, there are multiple discharge ports, which can sort a material into 2-7 different particle size specifications.

Stainless Steel Rectangular Vibrating Screen

To meet the advanced hygiene and hygiene parameters of industries such as food & beverage and pharmaceutical, its closed construction prevents leakage and helps to keep sieved substances free from outside interference.

Air-cooled Rectangular Vibrating Screen

The fan cooling system is added, which can continue to sieve high-temperature materials after cooling down, effectively reducing the difficulty of sieving high-temperature materials.

Plastic Rectangular Vibrating Screen

It is made of polypropylene material, also known as PP material, which is made by special processing technology to meet the screening operations of acid, alkali and corrosive materials.

Rectangular screen relies on two reverse motors with the same frequency to make the material jump straight forward on the screen surface. After a large number of broken materials with different particle sizes and mixed thickness enter the screen surface, only a part of the particles contact the screen surface. Due to the screen box Vibration, the material layer on the sieve is loosened, so that the gaps that exist in the large particles are further expanded, and the small particles take the opportunity to pass through the gap and transfer to the lower layer. Due to the small gap between the small particles, the large particles cannot pass through, so the original chaotic arrangement The particle group is separated, that is, it is stratified according to the particle size, forming a regular arrangement of small particles at the bottom and coarse particles at the top, so as to achieve the purpose of screening and sorting materials.

Linear screening and conveying

Uniform linear conveying action, driven by single/double vibrating motors. The material is thrown up on the wire surface to move in a straight line, and at the same time completes multi-layer grading and parallel conveying.

High screening efficiency

Primarily used to remove foreign matter and separate a product into different particle size specifications, meshes can range from 3/8 inch (10 mm) to 400 mesh (38 microns).

Multi-layer system

It can realize multi-layer simultaneous screening, and can simultaneously screen 2-6 kinds of materials of different grades in one operation.

High throughput

Screening areas from 500mm to 1,500mm wide and 1,500 to 4,000mm long are available, allowing throughputs of up to 20 t/h.

High screening efficiency

Unique grid structure, no mixing and crossing phenomenon. The inclination angle of the screen surface can be adjusted to balance the precision and output of the screen, and the efficiency can reach 96%.

No dust

The fully enclosed structure can ensure no dust pollution during the screening process, and can be used for automatic operations in assembly line production.

Rectangular screen for melting bean grading

Rectangular screen for wheat bran

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

1. The shape and size of the sieve hole: the circular sieve hole has a smaller particle size, and the square sieve hole has a larger material size. The size of the sieve hole is reasonably configured according to the material to be screened. 2-2.5 times.

2. Length and width of the screen surface: the wider the screen surface width, the thinner the material layer thickness will be, the greater the output, the longer the screen surface length, the longer the screening time, the more opportunities to pass through the screen, and the higher the screening efficiency. Generally, the ratio of width to length is 1:2~1:3.

3. Inclination angle of screen surface: Under normal circumstances, the rectangular screen can be installed at a certain angle. If the inclination angle is too small, the moving speed of the material will be slow, and the productivity will be greatly reduced. If the inclination angle is too large, the discharge will be too fast and the screening efficiency will be reduced. So the angle of inclination should be appropriate. Generally, we recommend that the slope of the linear vibrating screen is 0-15°. If you want to screen special materials, you can increase the slope appropriately, but it should not exceed 25°.

4. Motor excitation force: It must be higher than 30% of the total weight of the rectangular vibrating screen.

Rectangular vibrating screen can be designed and customized according to the actual use requirements, such as adding a distributor at the inlet, the shape of the inlet (round/square/tubular), size and height of the outlet. In addition, it can also be customized according to the requirements of different industries and on-site The process requires special customization:

Air-cooled rectangular screen: suitable for high-temperature materials, which can be screened after effectively reducing the temperature of the materials.

Adjustable rectangular screen: adjust the angle and height of the linear vibrating screen according to the material screening process.

Suspended rectangular screen: Screening equipment that can be installed in the air can save the space of the screening site

Silo-type rectangular screen: Equipped with a feeding bin, the feeding speed can be controlled by adjusting the plug-in of the feeding bin.

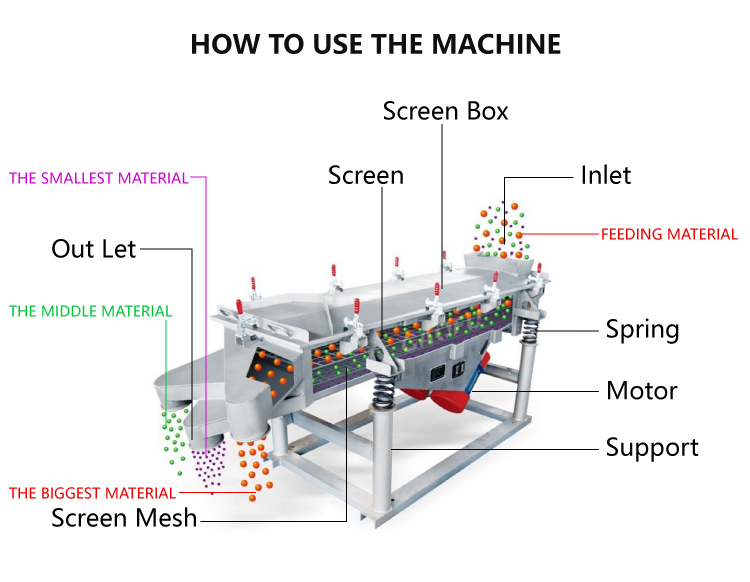

Rectangular vibrating screen is mainly composed of feed inlet, dust cover, screen box, screen mesh, discharge outlet, vibration motor, force guide plate, shock absorbing spring and base from top to bottom.

Screen: It is mainly used for screening materials. The aperture size of the screen ranges from 2 mesh to 200 mesh. There are many types and can be installed according to different screening requirements.

Screen box: The screen box is mainly used to hold the materials that need to be screened. The product is subjected to the action of the vibrating motor in the screen frame and makes a parabolic motion on the screen to achieve the purpose of screening.

Dust cover: The dust cover can solve the problem of dust when sieving powdery materials.

Inlet and outlet: The material enters the screen box from the inlet and is automatically discharged from the outlet after being screened;

Vibration motor - force guide plate - shock absorbing spring: The vibration force generated by the vibration motor drives the movement of the screen box through the conduction of the force guide plate and shock absorbing spring, and the material moves on the screen to achieve the purpose of screening.

1. Manufacturing materials:

Our rectangular vibrating screens are available in full 304/316 stainless steel, contact 304/316 stainless steel and full carbon steel upon customer request.

2. Surface treatment:

The surface treatment of our vibrating screens can be mirror polished, brushed or sand blasted, for carbon steel machines, it is painted.

3. Customized inlet and outlet:

The inlet and outlet can be customized, such as customizing the feed hopper, the size of the inlet and outlet, the shape and direction of the outlet.

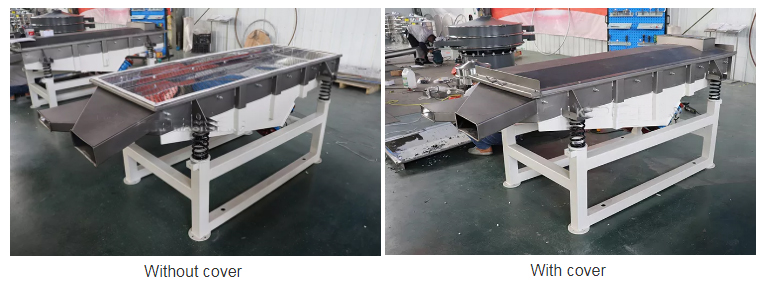

4. With or without cover:

The machine can be designed as open or fully sealed. The upper cover can be designed with multiple observation holes to check the screening of materials.

| Product | Image | Proportion | Mesh Size | Model | Method | Capacity (kg/hour) |

| Millet |  |

0.15 | 250 mesh | DZSF-515-2s | dry | 600 |

| Quartz sand |  |

1.6 | 70 mesh | DZSF-1540-3s | wet | 30000 |

| raisin |  |

0.83 | 60 mesh | DZSF-520-1s | wet | 6000 |

| sunflower seeds |  |

0.04 | 80 mesh | DZSF-525-1s | dry | 7100 |

| Plastic particles |  |

0.95 | 3mm | DZSF-515-2s | dry | 500 |

| flour |  |

0.6 | 24 mesh | DH-515-3S | dry | 1500 |

| Iron ore powder |  |

2.3 | 150 mesh | DZSF-1020-3s | dry | 10000 |

| slag |  |

4 | 5mm | DZSF-1020-1s | dry | 10000 |

| sawdust |  |

0.2 | 80 mesh | DZSF-1030-3S | dry | 18000 |

| Emery |  |

4 | 60 mesh | DZSF-515-1S | dry | 300 |

| wood flour |  |

0.4 | 120 mesh | DZSF-1036-4s | wet | 2000 |

| activated carbon |  |

0.8 | 36 mesh | DZSF-515-1s | dry | 500 |

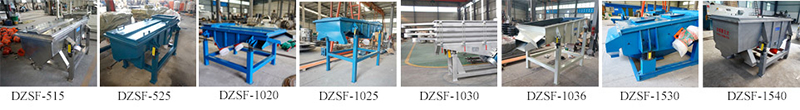

Xinxiang Dahan rectangular screen manufacturer has been established for 15 years. The company has passed ISO and CE certification. The models include DZSF-520, DZSF-525, DZSF-530, DZSF-1020, DZSF-1025, DZSF-1030, etc. According to the characteristics of materials, carbon steel and stainless steel materials can be selected, and 1~6 layers of screen mesh can also be selected according to the screening purpose. If you have special requirements, we can also customize different configurations and designs according to the user's process requirements.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.