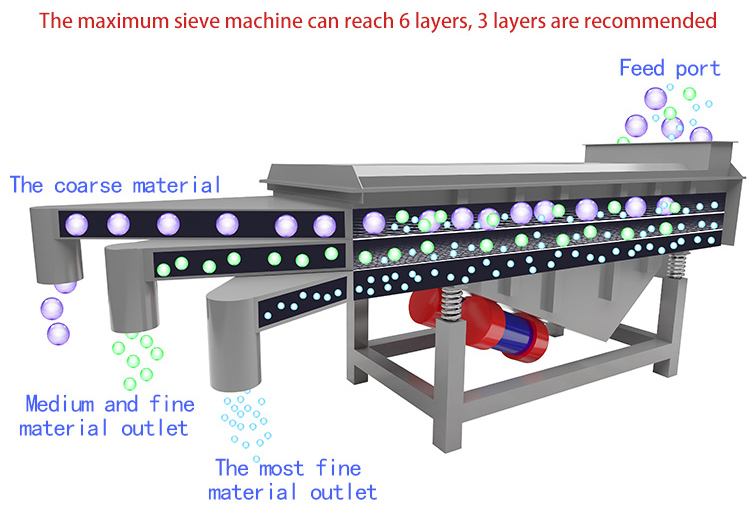

Square linear vibrating screen is also called square vibrating screen. Its main functions are grading, filtration and impurity removal. Two vibrating motors are used as the vibration source to make the material jump straight on the screen surface, and the material enters the screen surface evenly. The feeding port of the linear vibrating screen comes out from the feeder, and a variety of materials are produced through the multi-layer rectangular screen and discharged from each discharge port.

Square linear vibrating screen sieving up to 200 mesh (0.074mm), 6-layer design, you can continuously sieve up to 7 levels of product separation in one operation.

The square linear vibrating screen is mainly composed of a screen box, a screen frame, a screen, a vibration motor, a motor base, a damping spring, a bracket, etc. The square linear vibrating screen is driven by a double exciter. When the two exciters are synchronized, When rotating in the reverse direction, the excitation force generated by the eccentric block cancels each other in the direction parallel to the motor axis, and stacks in the direction perpendicular to the motor axis to form a resultant force, so the trajectory of the screen machine is a straight line. The two motor shafts have an inclination angle relative to the screen surface. Under the combined force of the exciting force and the material's self-gravity, the materials are thrown up and jump forward on the screen surface for linear motion, so as to achieve the purpose of screening and grading the materials.

Square linear vibrating screen for sand

Square vibrating screen with belt conveyor

1. It can screen granular materials below 400 mesh, and can screen up to 6 kinds of materials with different particle sizes at the same time to meet the needs of different customers

2. The way of the material on the screen surface is long, the screening efficiency can reach more than 96%, and the output per hour can reach 20 tons.

3. Screening and grading materials, and at the same time transporting materials over a long distance.

4. According to the particle size, sieving probability and productivity, the screen spacing and inclination can be changed.

5. We can design different sizes and structures according to the production site

6.Rectangular separators are provided with high quality suspension that virtually eliminates transmitted vibrations;

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

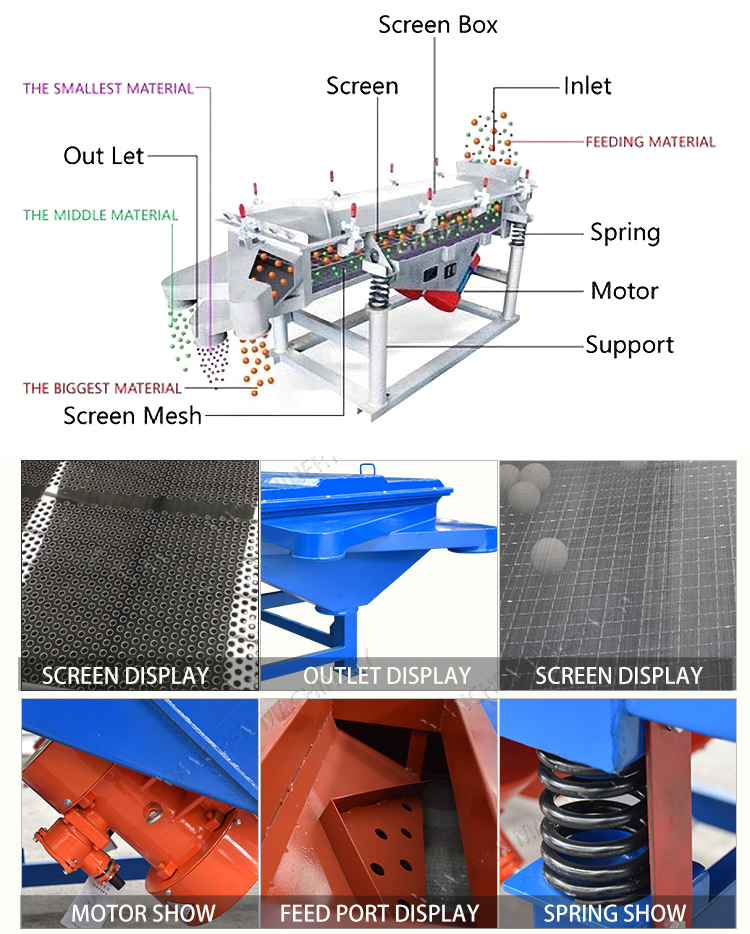

Square linear vibrating screen is mainly composed of screen box, screen frame, bracket, vibration damping spring, motor pedestal, vibration motor, screen mesh and so on.

Screen box: The material is fixed on the screen without leakage, which ensures the efficient and normal screening of the material, and has a certain strength and rigidity.

Screen frame: used to maintain the flatness of the screen and maintain the normal screening work of the linear screen.

The bracket "mainly plays the role of fixing and supporting the entire screen body, so that the vibrating screen can be fixed in one place for stable screening work.

Shock-absorbing vibration spring: reduce the vibration force generated by the vibrating screen to the frame during the working process, and completely protect the long-term stability of the frame.

Motor base: mainly plays the role of fixing the motor, ensuring that the position of the motor is fixed and not moving, and ensuring the normal operation of the linear vibrating screen.

Vibration motor: drive the screen of the linear vibrating screen to vibrate, so that the material can be better screened.

Screen: Screen and classify the materials to obtain the qualified size of the product materials.

| General requirements | Model | DZSF-520/525/530/1020/1025/1030 |

| Number of Layers(L) | 1-6(Suggest ≤ 3) | |

| Main Material | Stainless Steel(304/316L)•Carbon Steel(Q235)•PP | |

| Number of vibrations(times/min) | 960 | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor | |

| other | Please click here to contact us |

Chemical industry: fertilizer, urea, petroleum coke, resin, coating, cosmetics, paint, etc.;

Pharmaceutical industry: industrial medicines, Chinese medicine powder, granular pills, pellets, etc.;

Food industry: soybeans, chestnuts, steamed buns, spices, powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.;

Metallurgical industry: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, Quartz sand, metal powder industry, mining industry, etc.;

Other industries: plastics, abrasives, waste oil, wastewater, dyeing and finishing wastewater, papermaking, additives, activated carbon, carbon, etc.

The selection of square linear vibrating screen and your use of demand has a lot to do with the following information you need to provide.

Ⅰ.If you have ever used the screen machine

Kindly please tell us its DIAMETER,LAYERS,MESH SIZES,MATERIALS.

Ⅱ. If never use the machine until now

Please offer us the info about material as below:

1.The name of the material.

2.Material characteristics (e.g. specific gravity, bulk density, water content, fluidity, adhesion, electrostatic properties, etc.)

3.The purpose of use (sieving / debris / liquid filtration / media separation)

4.How many layers do you need? Mesh size of each layer?

5.Expected processing capacity per hour (Kg/h)

In this way,we can precisely choose the matching model for you to meet your use requirements.

6.Voltage(V),Frequency(Hz),Phase(P)

Xinxiang Dahan Machinery Co., Ltd. mainly produces square linear vibrating screens, and can also adopt special designs (such as air-cooled, mobile, hanging, etc.) according to customer needs. From product research and development, design, production, production manufacturers have technical personnel to follow up to ensure every link of the product.

Quality assurance: Dahan manufacturers have obtained ISO and CE international quality certifications. In addition, the manufacturers also carry out regular random inspections and test machines to ensure the quality of their products. For each user, the manufacturer will randomly check the test machine before delivery.

Service Guarantee: The manufacturer provides delivery within 3 days, door-to-door delivery and free installation, as well as 24-hour customer service online to answer questions, return product packages within 360 days, and return and exchange vulnerable parts within 31 days.

After-sales guarantee: The manufacturer provides a service model of follow-up service by service personnel for the after-sales service of the product, and conducts regular return visits. If the product has some operation problems, the service personnel can be consulted, and at the same time, it can also carry out after-sales items such as operation training.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.