A conveyor specially designed for the efficient and safe handling of plastic granules or pellets.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Material particle size: 25-70mm

Lifting capacity: 0-50m3/h

Lifting height: ≤10 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

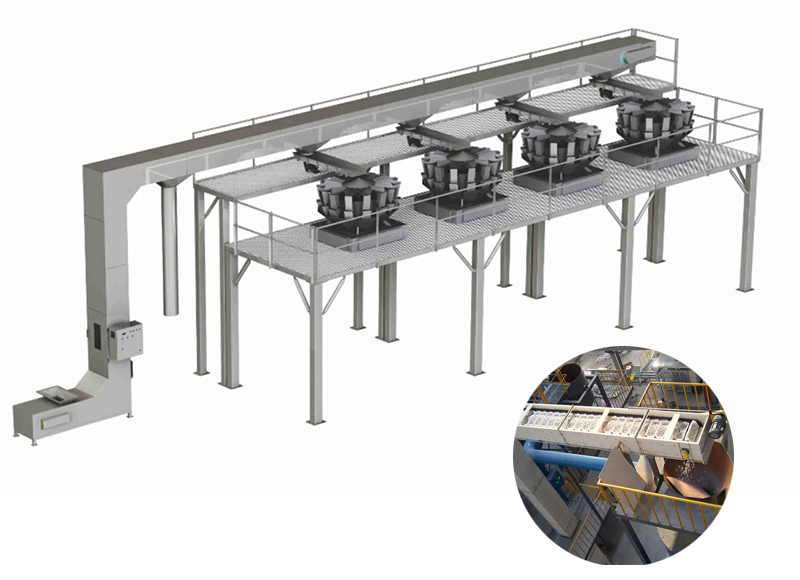

Application: Used in the plastics industry to lift granular materials such as plastic pellets from the ground or storage warehouses to high places.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Plastic particles bucket elevator is mainly used in the plastics industry to transport and lift various plastic particles. It is suitable for lifting raw material particles (such as polyethylene, polypropylene, etc.) to mixing or molding equipment, or in the plastic recycling process, lifting cleaned plastic particles. Generally speaking, the particle size range of plastic particles that can be transported by bucket elevators is between 0.5mm-10mm.

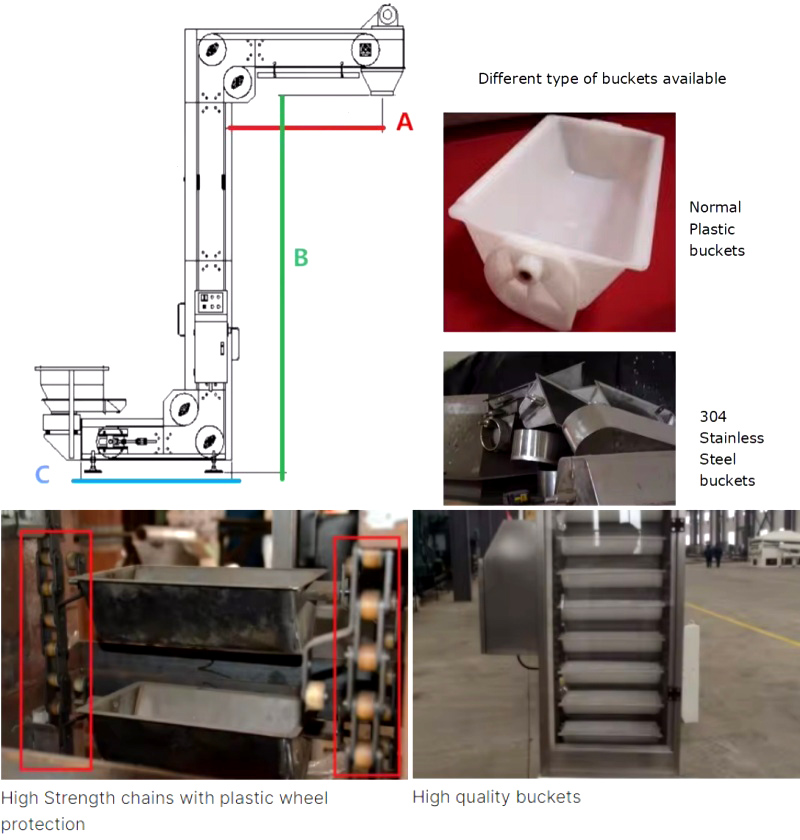

The design of a plastic particles bucket elevator takes into consideration the characteristics of plastic particles, such as their size, shape, and flowability. The buckets are typically made of durable materials, such as reinforced plastics or metals, to withstand the abrasion and impact of handling the particles.

For plastic particles of different particle sizes, bucket elevators can choose different types to meet specific conveying needs.

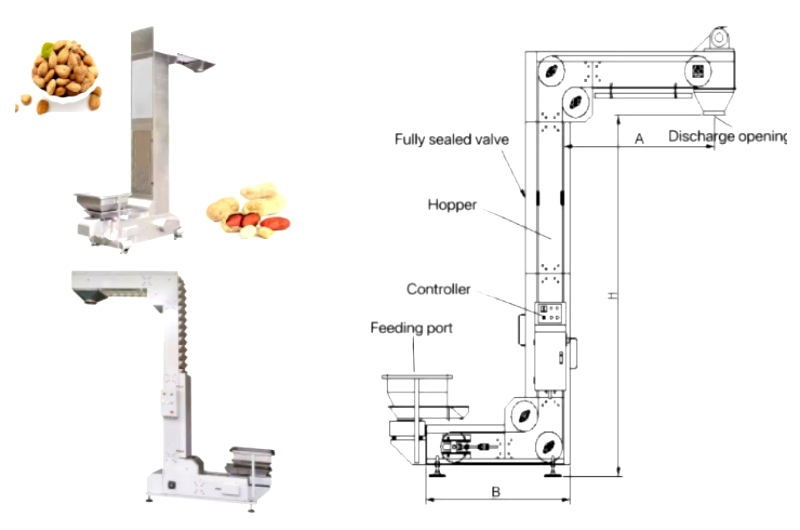

1. Fine-grained plastic particles (0.5mm-1mm): The particles are small and easy to fly, and the equipment sealing requirements are high. The bucket elevator adopts a fully enclosed structure, which can effectively prevent dust from flying, and is suitable for occasions with high environmental requirements.

2. Medium-sized plastic particles (2mm-5mm): The particle size is moderate, the equipment requirements are relatively low, the structure is simple, and the price is low. It is suitable for the transportation of most medium-sized plastic particles.

3. Large-sized plastic particles (5mm-10mm): The particle size is large, and the equipment carrying capacity requirements are high. A buffer device is set at the hopper discharge port to reduce the impact of materials on the equipment and extend the service life of the equipment.

Plastic particles bucket elevator uses a motor to drive the bucket lifting bucket to rise or fall along the guide rail. The bucket lifting bucket loads the plastic particles into the bucket during the movement. As the lifting bucket moves, the plastic particles are transported to the upper part. When the lifting bucket reaches the top, the plastic particles in the bucket are dumped to the discharge port to achieve vertical transportation. The lifting bucket drops to the bottom again, and the conveying process is cycled.

Plastic particles bucket elevators or bucket elevators adapted to handle plastic particles can find application in a variety of industries involving the handling, processing or transportation of plastic particles or particles. Some common applications include:

Plastic Manufacturing: Used to feed plastic particles to extruders, mixers or molding machines, and to convey finished or intermediate plastic products.

Packaging and bagging: Elevating plastic particles to higher heights for gravity-based filling or feeding into packaging machines. It facilitates consistent and controlled material flow during packaging.

Plastic mixing: It can be used to transport plastic granules to compound equipment such as mixers, extruders or granulators to ensure a continuous and efficient production process.

Plastic pellet production

A plastic pellet production plant needs to transport plastic pellets from the production line to the silo. They chose a plastic pellet bucket elevator because of its ability to move large quantities of material in an efficient and safe manner.

Material: plastic pellets

Conveying capacity: 10 tons/hour

Lifting height: 10 meters

Plastic recycling

A plastic recycling company needs to transport recycled plastic pellets to a washing line. They chose a plastic pellet bucket elevator because it can effectively prevent dust generation and avoid contamination of plastic pellets.

Material: recycled plastic pellets

Conveying capacity: 5 tons/hour

Lifting height: 5 meters

Plastic packaging

A plastic packaging company needs to transport plastic pellets to packaging machines. They chose a plastic pellet bucket elevator because of its ability to handle plastic pellets gently, preventing breakage.

Material: plastic pellets

Conveying capacity: 2 tons/hour

Lifting height: 3 meters

Efficient and Reliable Material Handling

Provide efficient vertical or inclined transportation of plastic particles to ensure smooth and continuous flow of materials. It transfers plastic pellets between different process stages or storage areas without manual handling or additional conveying equipment.

Minimal Dust Generation and Product Contamination

The enclosed construction keeps dust contained, reducing the risk of explosions and improving workplace air quality.This also minimizes product contamination, ensuring the purity of the plastic particles.

Gentle Handling of Plastic Particles

The buckets scoop and lift the material, preventing crushing or degradation that can occur with other conveying methods like screw conveyors.This is especially important for fragile or heat-sensitive plastic particles.

Easy to Clean and Maintain

The simple design allows for easy access to the interior of the elevator for cleaning and maintenance.This helps to minimize downtime and ensure optimal performance.

Configurable for Horizontal or Inclined Conveying

Bucket elevators can be designed for both vertical lifting and horizontal conveying of plastic particles.This versatility allows for integration into various production line layouts.

Space optimization

They require less floor space than other horizontal conveying methods. This is especially beneficial for facilities with limited space available, making efficient use of the available vertical space.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Plastic particles bucket elevators usually consist of motors, lifting barrels, guide rails, support frames and discharge ports. The motor drives the lifting bucket to rise or fall along the guide rail. The lifting bucket is equipped with a bucket for loading and transporting plastic particles. Guide rails support the movement of the lifting bucket to ensure stability. The support frame is used to support the entire equipment structure. The discharge port is located at the top and is used to release the plastic particles delivered to the top.

For conveying plastic particles, the bucket elevator of plastic particles can have some special designs to meet specific requirements and application scenarios, including but not limited to the following designs:

Dust-proof design: In view of the dust that may be generated by conveying plastic particles, the elevator can be designed with a dust cover or take other measures to reduce particle leakage and environmental pollution.

Anti-blocking design: In view of the problem that plastic particles may be blocked during the conveying process, the elevator can be designed with anti-blocking devices, such as blocking sensors, automatic cleaning devices, etc., to ensure continuous and stable conveying.

Wear-resistant design: Since plastic particles may cause wear to the equipment, the elevator can use wear-resistant materials or surface coatings to extend the service life of the equipment.

Adjustable speed design: According to different conveying requirements, the elevator can be designed with an adjustable speed function to adjust the conveying speed and amount and improve production flexibility.

Anti-accumulation design: In view of the problem that plastic particles are easy to accumulate inside the elevator, a reasonable bucket cup shape and spacing are designed to prevent particle accumulation from affecting the conveying effect.

Plastic particles bucket elevators are widely used in the plastics industry. Choosing the right bucket elevator is crucial to ensure conveying efficiency and equipment life. In the selection process, the following aspects need to be considered comprehensively:

1. Plastic particle characteristics: Plastic particles of different particle sizes require different types of buckets and chain speeds. Generally speaking, fine-grained particles require elevators with better sealing, while large-size particles require elevators with stronger load-bearing capacity. For plastic particles with strong abrasiveness, hoppers and chain plate materials with good wear resistance should be selected. Plastic particles with high viscosity may require anti-sticking measures, such as Teflon buckets.

2. Production requirements: Determine the required conveying volume based on the production capacity of the production line.

3. Lifting height: Determine the lifting height based on the layout of the equipment and the height of the plant.

4. Working environment: In high temperature environments, high temperature resistant materials should be selected, and anti-corrosion measures should be considered in high humidity environments.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.