Multi discharge z type bucket elevator is a z type elevator with multi-point blanking, which is mainly used to lift products from low to high. Less than one outlet, the number of openings can be up to 7 positions, each position is about 2 meters apart (this depends on the size of the multi-head scale, etc.), suitable for feeding multiple silos in a row, and solves the problem of conveying and ascension puzzles.

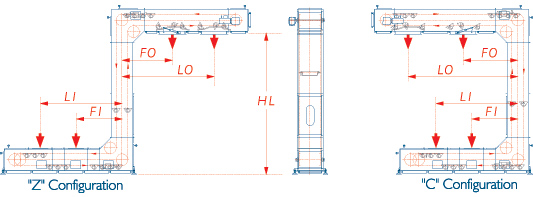

Multi discharge z type bucket elevator has multiple discharge ports to discharge material at the same time, which is suitable for feeding multiple silos in a row. It can be used for Z-type feeding, C-type feeding, ZC mixed feeding and multi-point feeding, multi-point feeding Automatic production lines such as unloading are suitable for vertical lifting of granular materials in grain, food, feed, chemical and other industries, such as corn, potato chips, plastic granules, peanuts, biscuits, candy, nuts, frozen food, activated carbon, etc.

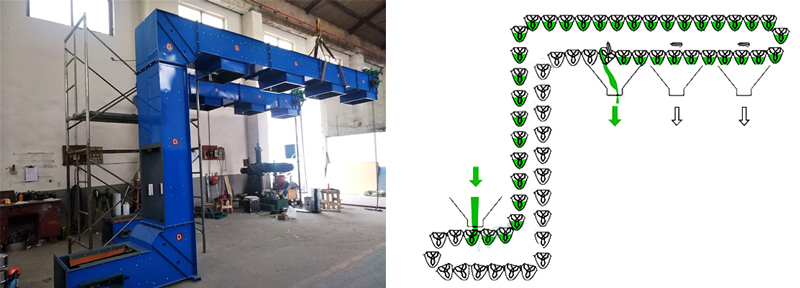

When the multi discharge z type bucket elevator is working, the geared motor drives the two sprockets to move synchronously through the bearing, so that the two chains meshing with it move synchronously on the closed track. When the material is transported to the feeder, it slides into the horizontal forward hopper, and then the excess material in the hopper is brushed into the next hopper by the brush of the feeder. Since the material slips into the hopper, it is not Forced scraping reduces material breakage. In this way, through the synchronous movement of the two chains, the hopper between the two chains moves continuously on its closed track. Under the action of the turning wheel, the hopper is turned over, and the material in the hopper falls into the temporary storage bin of the matching equipment from the discharge port of the elevator.

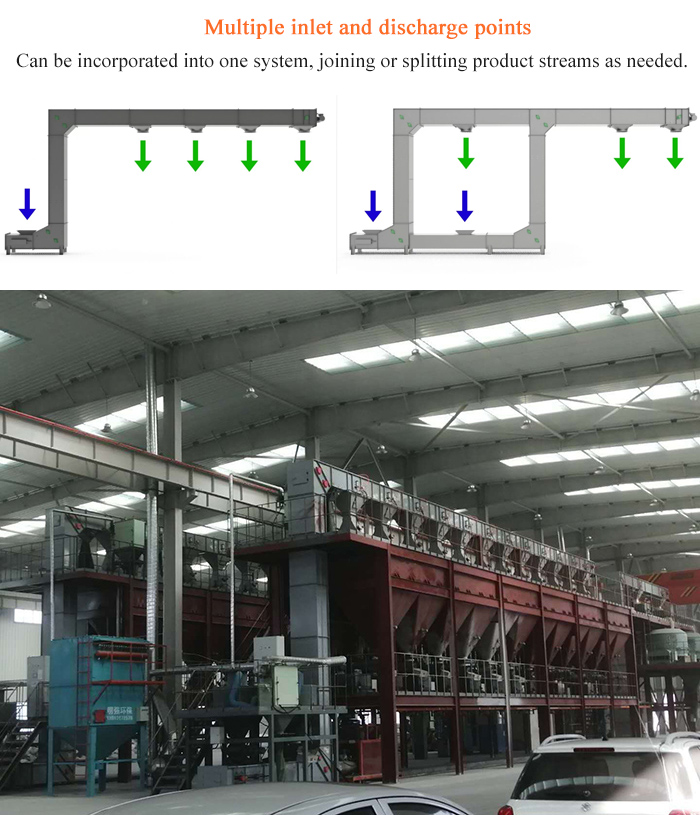

1、Multiple inlet and multiple discharge points can be incorporated into one system, joining or splitting product streams as needed.

2. The number of discharge ports can be up to 7 positions, and each position is about 2 meters apart (it depends on the size of the multi-head scale, etc.)

3. The conveying speed can be adjusted according to the conveying volume, and the discharge height, feed height and length can be customized.

4. Gently handle delicate materials to maintain product integrity, including pet feed, puffed food, feed, confectionery industry, etc.

5. The shell of the whole machine is closed, the material leakage is less when the machine is running, and the dust flying is reduced at the same time.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Address::China,Yanjin county forest park gate to the west 1000 meters north road.