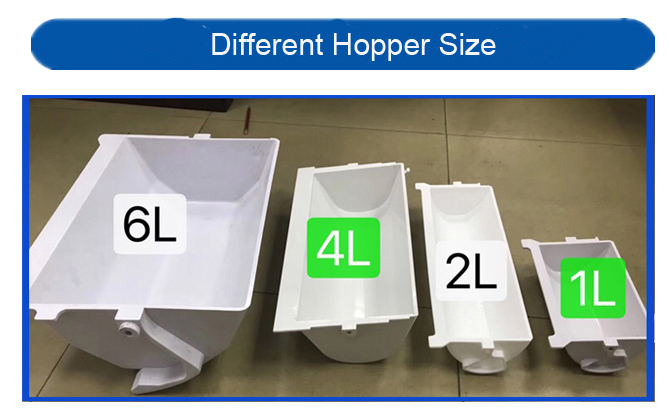

Bucket capacity of Z-type bucket elevator: 1.8L, 2.4L, 3.6L, 6L, 10L, the larger the bucket capacity, the greater the lifting capacity. It is used for conveying and lifting various bulk and block materials in the vertical direction. Its capacity is mainly affected by the following factors:

Based on the provided bucket capacities (1.8L, 4.0L, and 6.0L) for Z-type bucket elevators, here's an overview of their corresponding estimated output ranges and suitable applications:

1.1.8L Bucket Capacity:

Output Range: 0.5-2m³/h

Suitable Applications:

Small-scale grain handling, such as farm silos or feed mills

Conveying lightweight materials like powders, seeds, or small parts

Laboratory or pilot plant applications

| Bucket Volume | 1.8L |

| Capacity | 0.5-2m3/h |

| Exit Height (m) | 1.5-8 |

| Vibrator Hopper Volume | 50/70L /110L |

| Speed of Chain | 14m/min |

| Power | 0.25kw |

2.4.0L Bucket Capacity:

Output Range: 6-12m³/h

Suitable Applications:

Food processing plants for conveying flour, sugar, spices, or grains

Pharmaceutical or chemical industries for handling powders, granules, or tablets

General industrial applications for transporting medium-sized materials like bolts, nuts, or small components

| Bucket Volume | 4L |

| Capacity | 6-12m3/h |

| Exit Height (m) | 1.5-8 |

| Vibrator Hopper Volume | 70L /110L/340L |

| Speed of Chain | 14.2m/min |

| Power | 0.75kw |

3.6.0L Bucket Capacity:

Output Range: 18-20m³/h

Suitable Applications:

Large-scale grain silos or storage facilities

Mining operations for conveying sand, gravel, or crushed rocks

Construction sites for handling concrete aggregates or bulk materials

Additional Considerations:

| Bucket Volume | 6L |

| Capacity | 18-21m3/h |

| Exit Height(m) | 1.5-8 |

| Vibrator Hopper Volume | 70L /110L/340L |

| Speed of Chain | 16.3m/min |

| Power | 1.5kw |

2. Lifting height: The lifting height of the Z-type bucket elevator is also an important factor for its capacity. The higher the lifting height, the longer the material needs to be lifted and the smaller the corresponding capacity. Therefore, when designing and selecting a Z-type bucket elevator, it is necessary to select the appropriate model and specification according to the actual lifting height.

Z-type bucket elevator capacity calculation

Q = (n * η * S * v * ρ) / 3600

in:

Q is the output of the elevator (unit: cubic meters/hour or tons/hour);

n is the number of buckets running per hour;

η is the efficiency of the elevator (usually 0.85-0.95);

S is the volume of a single bucket (unit: cubic meters);

v is the lifting speed of the elevator (unit: meters/second);

ρ is the density of the material (unit: kilogram/cubic meter).

For materials with different properties, the specific Z-type bucket elevator output will vary.

1. Wheat: 4.0L bucket volume, efficiency 0.9, lifting speed 1.0 m/s, and 60 buckets running per hour. According to the typical density range of wheat (600-800 kg/cubic meter), the output can be estimated at Between 40-53 cubic meters/hour or 35-46 tons/hour.

2. Potato chips: 6.0L bucket volume, efficiency 0.85, lifting speed 0.8 m/s, and 50 buckets running per hour. It can be estimated based on the typical density range of potato chips (250-350 kg/cubic meter) The output is between 18-25 cubic meters/hour or 15-21 tons/hour.

3. Feed: 1.8L bucket volume, efficiency 0.95, lifting speed 1.2 m/s, and 80 buckets running per hour. According to the typical density range of feed (500-700 kg/cubic meter), the output can be estimated at Between 57-80 cubic meters/hour or 48-67 tons/hour.

It should be noted that these estimates are based on some common assumptions and ranges, and actual output may be affected by other factors, such as material mobility, feeding method, elevator design and operating conditions, etc. For accurate yield estimates, it is recommended to refer to the technical data provided by the provider or conduct actual testing.

Additional Considerations:

Material Properties: The actual output of a Z-type bucket elevator depends on the material being conveyed. For instance, dense or cohesive materials may require a lower output range compared to free-flowing materials.

Elevator Speed: The speed of the elevator also influences output. Higher speeds generally lead to higher throughput.

System Configuration: Factors like discharge chute design, hopper size, and material feeding mechanism can also affect overall output.

Generally speaking, the capacity range of the Z-type bucket elevator is relatively wide, generally ranging from tens of tons to thousands of tons per hour. However, the specific capacity needs to be comprehensively considered and calculated according to the above factors to determine the specific capacity value.

If you have any questions about Z type bucket elevator production calculations or other related issues, or require a customized solution to meet your specific needs, please feel free to contact our team

Address:China,Yanjin county forest park gate to the west 1000 meters north road.