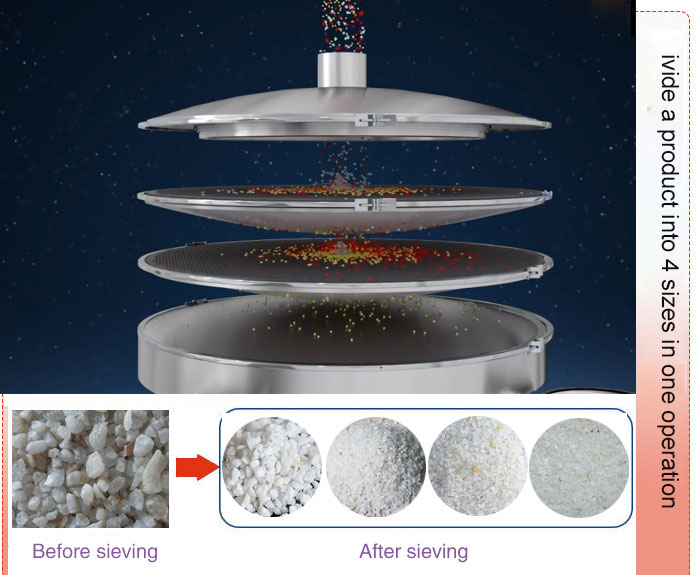

Three-layer, four outlet screening, screening and grading through up to 4 sieve plates, one product can be divided into 4 specifications

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screen frame: 3 layers

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

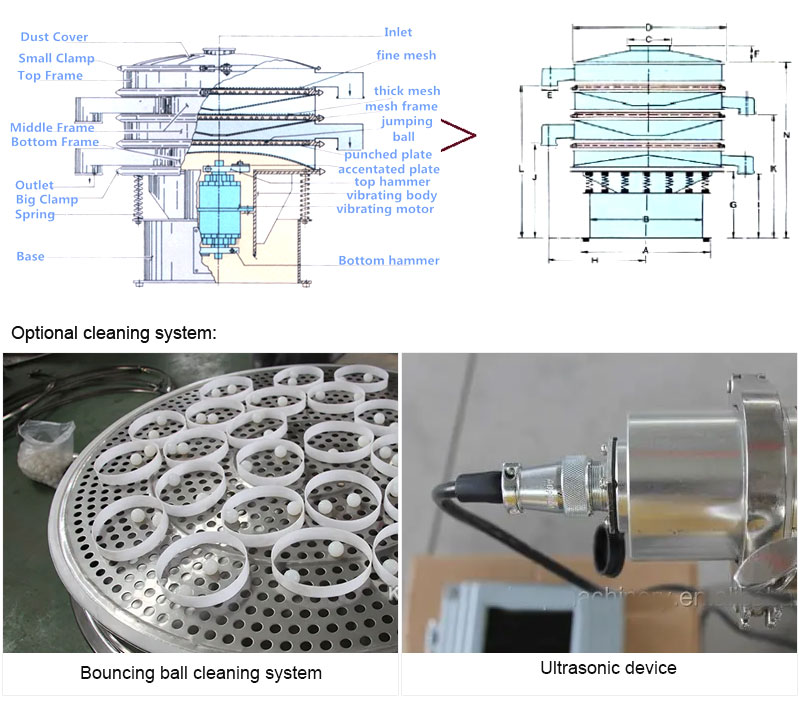

Cleaning system:Bouncing Ball/Ultrasonic Cleaning System

Material:Carbon steel Q235, Stainless Steel 304/316L, Plastic

Motor Power: 0.25-3kw

Application: Separation of oversized particles and foreign matter from products, solid-liquid separation of liquids, fineness control of suspended particles, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

3 deck vibrating screen is also called triple deck vibrating screen, which means that there are three layers of sieve plates and four outlets, that is to say, after the material passes through the inlet of the three-layer vibrating screen, it can be classified into 4 kinds of products with different specifications. The particle size ranges from From top to bottom in order. It becomes smaller and realizes the phenomenon of one feeding and multiple discharging. It can be used to screen dry powder or granular products as well as wet products and liquids. It can eliminate foreign matter in products through continuous filtration. It is widely used in food, medicine, metal powder, powder coating and other industries.

3 deck vibrating screen is suitable for continuous screening of products of different particle sizes, it can accurately separate particles of different particle sizes from the product, so that the final material can be classified into different sizes, it can continuously filter up to 4 grades of product separation with only 1 operation, and can Separation of mass components of solids from solid and grading materials according to particle size can be used for screening, grading and solid-liquid separation in pharmaceutical, chemical, food and metal powder industries.

3 deck vibrating screen adopts a vertical vibrating motor as the excitation source, through the eccentric weights at the upper and lower ends of the vibrating motor, the rotary motion is transformed into a three-dimensional motion of horizontal, vertical, and inclined, and is transmitted to the screen surface of the rotary vibrating screen. Enter the equipment through the material inlet. According to different screening requirements, the material passes through three layers of screens with different meshes. During this process, the cleaning device located under the screens of each layer continuously hits the screen. , so that the material can be screened smoothly, and effectively avoid the problem of material blocking. The material close to the pore size of the sieve passes through the sieve and is the undersize material, and the material larger than the pore size of the sieve is discharged from the outlet of this layer. , as the undersize, to complete the purpose of screening or filtering.

4 layers of classification

There are 3 different mesh screens to separate the mixed material into 4 finished products with different fineness.

Fine sieve

Capable of screening up to 500# and delivering the required output giving accurate particle size.

Increase flexibility

The compact all-in-one vibrating screen is easy to handle and can be used at different locations in the plant

Reduce downtime

Manually operated quick-release clamps allow for quick screen changes and easy cleaning

3 deck vibrating screen for foundry sand

3 deck vibrating screen for flower species

| General requirements | Diameter(mm) | 400/800/1000/1200/1500/2000 |

| Number of Layers(L) | 1-5(Suggest ≤ 3) | |

| Main Material | Stainless Steel(304/316L)•Carbon Steel(Q235)•PP | |

| Screen Mesh Number | 100-635 | |

| Transducer Installation Method | Built-in / External | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor | |

| other | Please click here to contact us |

3 deck vibrating screen is mainly composed of feeding port, screen mesh, screen box, dust cover, vibrating motor and discharging port.

Screen: It is composed of 3 layers of sieve plates, and carbon steel, stainless steel and other materials can be selected according to the screening materials.

Screen box: It has a certain rigidity and is welded by several steel plates with different thicknesses.

Screen frame: two different materials, wood and metal, can be selected, which are mainly used to ensure the smoothness of the screen.

Outlet: 4 outlets, one material can be sorted into 4 different granularity specifications, the outlet can be made into a circle, or a dust removal port can be reserved, which can be connected to the fan pipe, the direction of the outlet It can also be formulated as needed, left, right, down, and forward.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.