Mobile screw conveyor

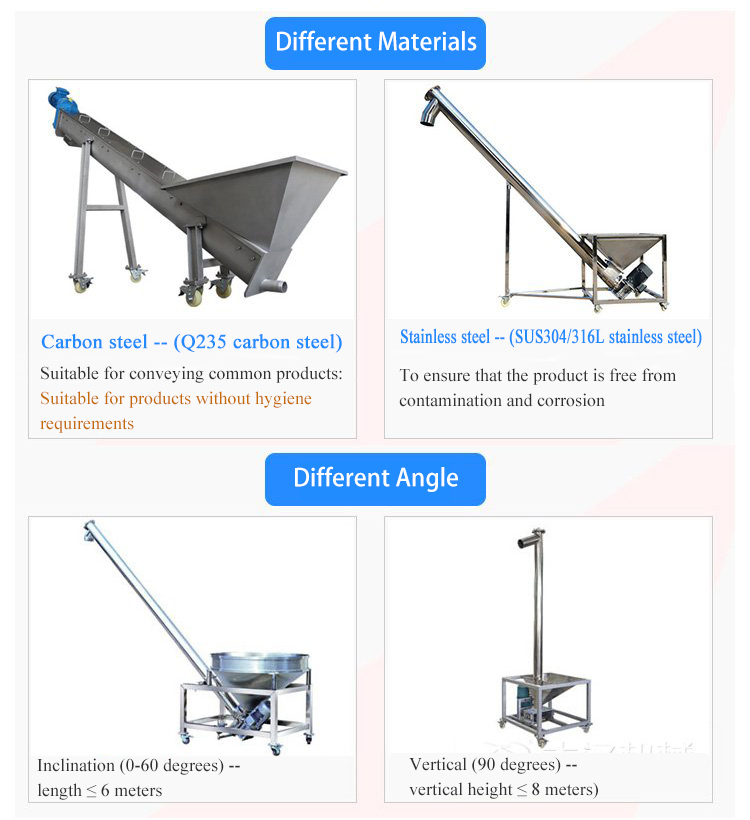

Mobile screw conveyor Stainless steel mobile screw conveyor

Stainless steel mobile screw conveyor Carbon steel mobile screw conveyor

Carbon steel mobile screw conveyor Mobile screw conveyor with barrel

Mobile screw conveyor with barrel Vertical mobile screw conveyor

Vertical mobile screw conveyor

The mobility of the system allows it to be used for multiple product applications in different areas of the plant

![]()

![]()

Price:$800.00-$32,000.00/Set

Consult now and enjoy a 10% discount

Pipe diameter: 102-325mm

Conveying capacity: 1.2-199m³/h

Conveying length: 2-70 meters

Conveying angle: 30-90 degrees

Screw speed: 25-140 rpm

Frame material: SUS304/carbon steel

Application: Material can be received from multiple outlets of feeders, grinders, mixers, and other process equipment, and can be moved at will depending on where the material is stacked

Commitment:

Mobile screw conveyor is composed of a frame mounted on casters, a support frame and a hopper, which can flexibly meet the installation requirements of most applications and mobile systems, so as to achieve flexibility in the factory, and can be moved freely according to the site situation, and can be pushed in and out of the warehouse by two people. It is widely used in feed, chemical, food processing, and grain processing, grain and grain storage, various additives, and bulk material transportation in construction engineering and other industries.

Mobile screw conveyors can be conveyed horizontally, inclined and vertically, using one conveyor to load bulk materials, ingredients or additives into a variety of processing and packaging machines, allowing equipment to be easily moved from one point to another.

The mobile screw conveyor is equipped with universal wheels at the bottom of the conventional screw conveyor, which is easy to move. , suitable for conveying bulk materials and other unfixed locations. It is used as a flexible mobile system in factories and is ideal for transferring most types of products, including food, pharmaceuticals, chemicals and plastics, from bulk bag unloading, machines, bag dump stations or silos, in non-fixed positions Operations, such as: ports, docks, stations, coal yards, warehouses, construction sites, sand and gravel yards, farms, etc.

Common applications: conveying and lifting of milk powder, flour, feed, solid medicine, veterinary medicine, pesticide, food additives and other powder and fine particle materials.

Mobile screw conveyor for conveying grain

Mobile screw conveyor for conveying flour

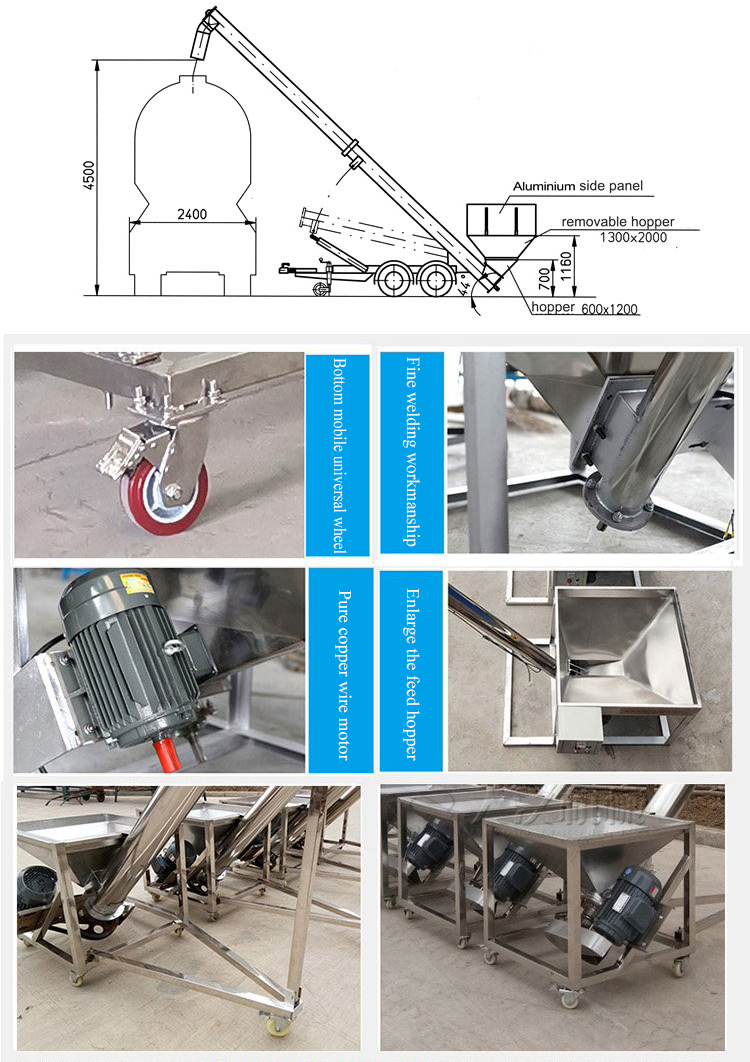

Can be moved flexibly

The system is mounted on a frame with locking casters for in-plant mobility that provide additional stability and safety.

Feed volume is adjustable

The feeding motor and vibration motor are controlled by their respective switches, the amplitude is adjustable, the feeding is uniform, and the feeding amount is adjustable.

Does not degrade or separate mixed products

The mobile conveyor's only moving part is a motor-driven spiral that rotates within a sealed tube to gently move material without degradation or risk of mixed-product separation.

Made of stainless steel

All material contact surfaces are made of stainless steel to hygienic or industrial standards, and the mobile frame is made of carbon steel with a durable industrial coating, also available in stainless steel.

Sealing system

Totally enclosed, suitable for dusty, corrosive or hazardous environments, reducing contamination problems of conveyed products.

Easy to clean

Flexible reversible auger, quick-removal auger and discharge valve ensure easy cleaning.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Notes for customer selection:

The screw machine is not suitable for conveying perishable, viscous, and agglomerated materials, because these materials will stick to the screw during conveying, and rotate accordingly without moving forward or form a material plug at the suspension bearing , so that the screw machine cannot work normally.

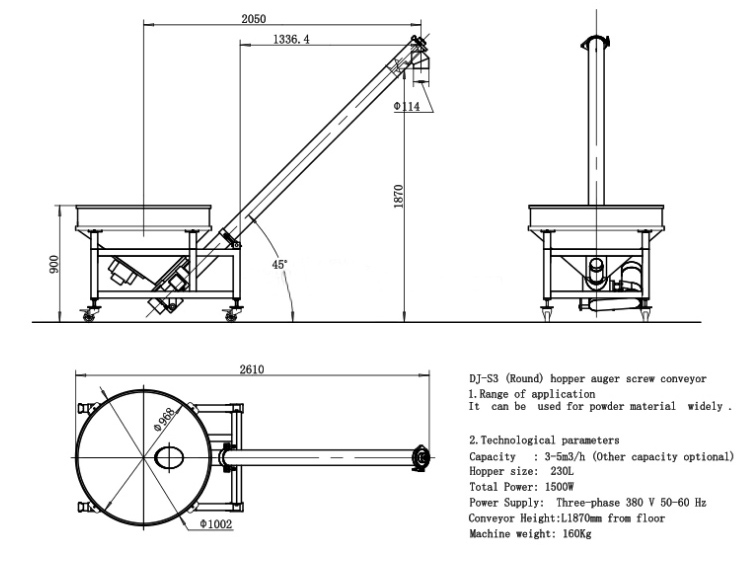

The diameter of the mobile screw conveyor is from 200 mm to 500 mm. There are five specifications in total, and the length is from 4 meters to 70 meters. There is a gear every 0.5 meters. propose.

The mobile screw conveyor is designed with a lifting mechanism, which can be used with conveyors and other equipment, and can also be used for grain filling. The machine is easy to move, simple to maintain, and has a large workload. It can also feed materials to our company's grain cleaning machine or other equipment.

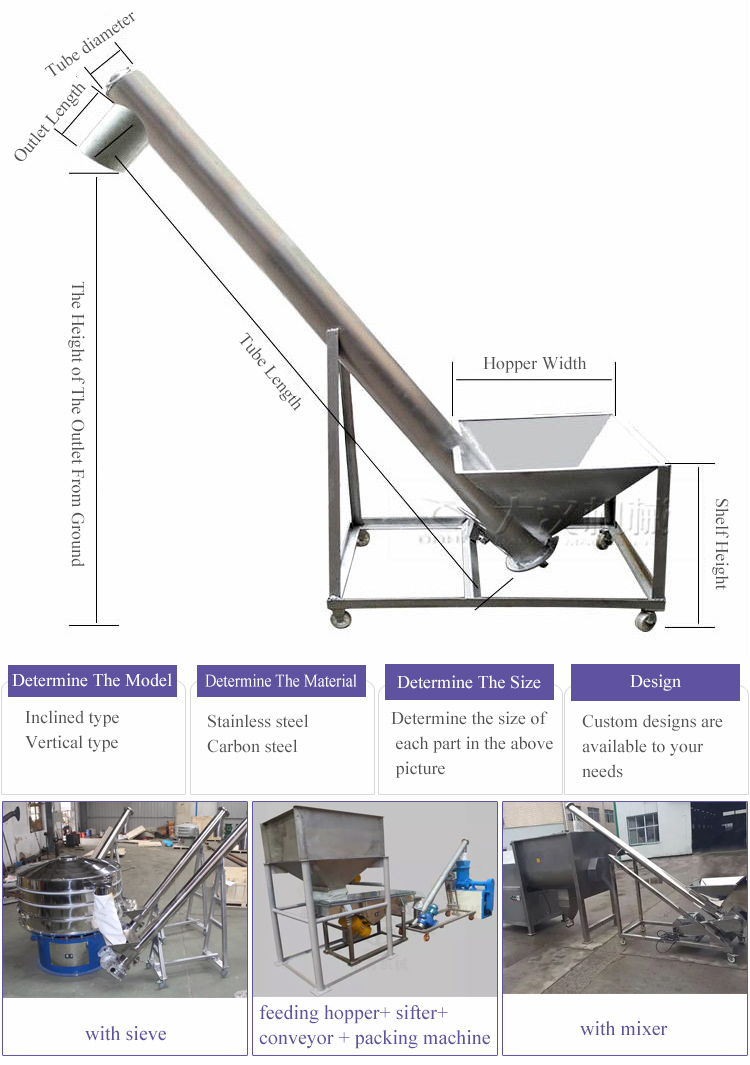

The motor device of the conveyor - can be designed at the discharge port of the screw conveyor, and the feed port of the auger conveyor - there are ribs to control the amount of feed. We can also customize the corresponding shape according to customer requirements. There are also mobile screw conveyors with the following configurations.

Mobile screw conveyor consists of a frame mounted on casters, a support frame and a hopper. The outer casing is connected by steel pipes through flanges to form a whole. The inlet and outlet and inclination angle can be designed and installed according to the site conditions.

Dual motors: screw motor and vibrating motor, each controlled independently.

Universal wheels: Universal wheels are installed under the equipment, which can be moved freely, especially suitable for operations in non-fixed positions such as bulk material loading.

Outlet: The outlet can be square or round, and the material can be stainless steel.

Motor: Use a pure copper motor, if you want to control the feeding speed, you can replace it with a variable speed motor.

Feed inlet: The size of the feed inlet can be made according to customer needs, the inclination is suitable, and it is not easy to store materials.

Mobile screw conveyors can be customized according to your requirements, such as flange diameter size, distance between inlet and outlet, installation inclination angle, shape (U-shaped, tubular, shaftless), size of feed inlet, etc., and can also be combined with sieve, mixer , supporting the use of silo.

Mobile screw conveyors are used to move both free and non-free-flowing bulk materials, the system is mounted on a frame with locking casters for mobility within the factory, by eliminating the heavy frame components typically used to support bulk bags, during operation Relying on the user's forklift or factory crane to suspend the bags above the unit, the system improves mobility and reduces costs.

China Xinxiang Dahan mobile screw conveyor manufacturer has nearly 14 years of production experience, factory direct sales, low price, 2-year warranty, reasonable selection and design according to the particle size of the conveyed material, conveying volume, conveying distance, and can also provide product customization services, custom-made Fast and short construction period.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.