Liftable mobile belt conveyor is also called mobile lifting belt conveyor, also known as mobile feeding conveyor. It can be freely expanded and contracted in the length direction, and the length of the conveyor can be controlled at any time. It can convey materials in two directions, and can be used in conjunction with other conveying equipment and material sorting systems to realize automatic production of materials in and out of storage or vehicle loading and unloading.

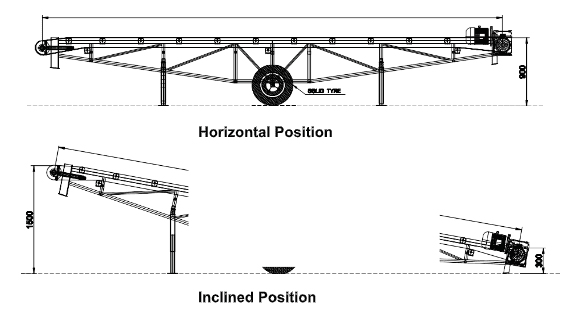

An adjustable height feature is a common feature of a liftable mobile belt conveyor. The adjustable height feature allows the conveyor to be raised or lowered to the appropriate height for loading and unloading, as well as for transporting materials to different areas within a facility. This feature is particularly useful when the conveyor is used in applications where the height of the loading or unloading location may vary, or when the conveyor needs to be adjusted to accommodate different types of materials.

| Specification | 6 Meters | 8 Meters | 10 Meters | 12 Meters | 15 Meters |

| Height Adjustable | 1.7-2.7 Meters | 2.5-3.7 Meters | 2-4 Meters | 2-4.5 Meters | 3-6 Meters |

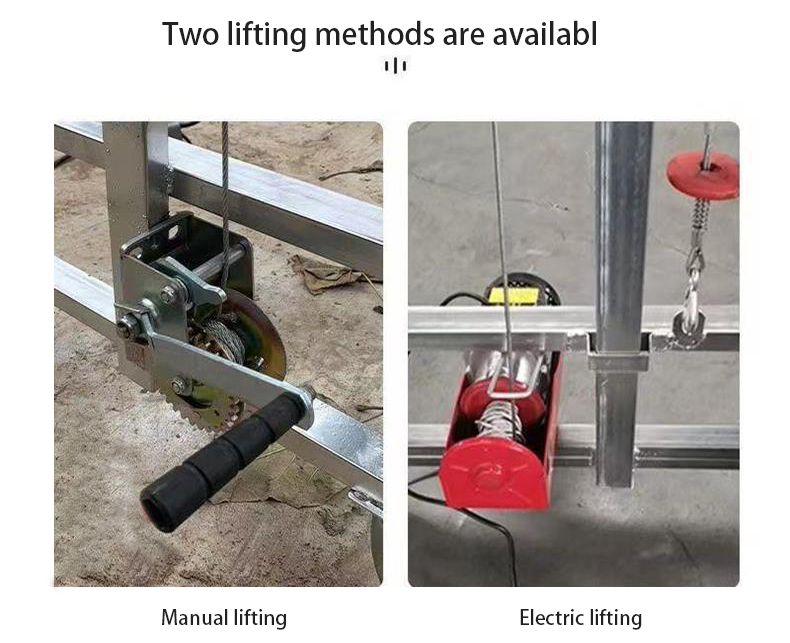

The mobile belt conveyor consists of a large frame, running wheels, universal wheels, lifting devices, etc. Under normal circumstances, the body is made of steel pipes to reduce its own weight and improve the mobility and portability of the belt conveyor. The lifting device is an electric lifting device, which reduces the dangers caused by manual lifting and reduces the work intensity.

The adjustable height feature of a liftable mobile belt conveyor is typically achieved through the use of a lifting mechanism, such as hydraulic or pneumatic cylinders, that are mounted on the frame of the conveyor. The lifting mechanism is controlled using a switch or lever, which allows the conveyor operator to adjust the height of the conveyor to the desired level. Some conveyor systems may also be equipped with sensors or automated controls that adjust the height of the conveyor based on the material being transported or the location of the loading or unloading point.

1.Some common applications of a liftable mobile belt conveyor with adjustable height include:

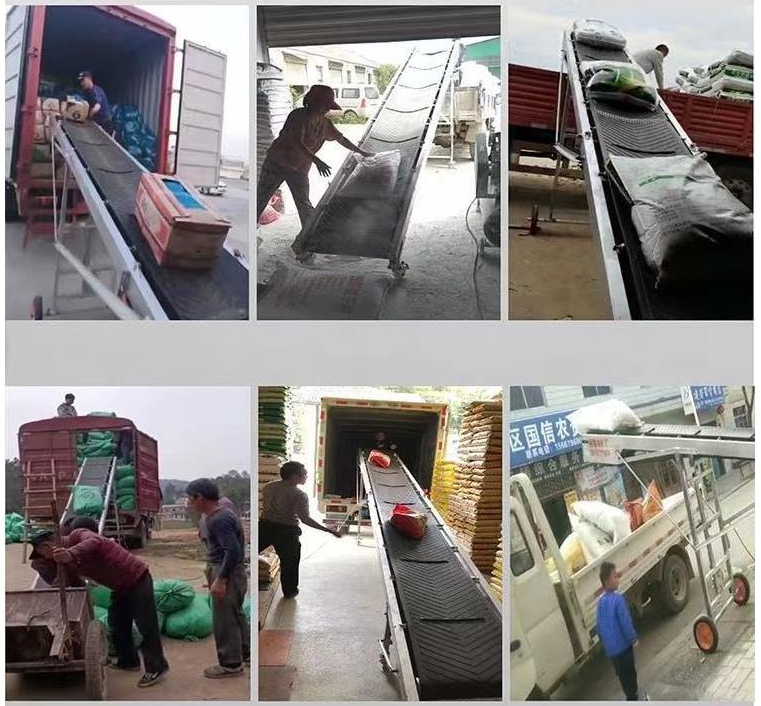

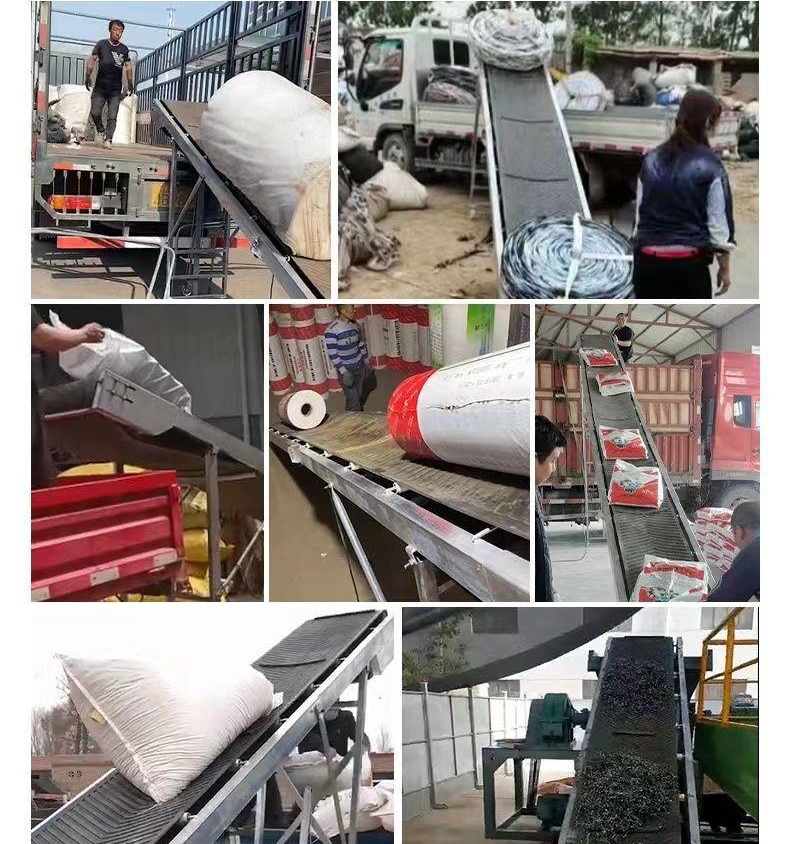

2 .Loading and unloading of goods from trucks or containers of different heights.

3.Transporting materials to multiple levels within a facility, such as different floors or mezzanines.

4.Moving materials over uneven terrain or obstacles, where the height of the conveyor may need to be adjusted to maintain a constant incline.

1. The machine is equipped with a lifting device, which can control the height. The belt can be loaded in the forward direction, and the belt can be unloaded in the reverse direction. The lifting height can reach 6 meters.

2. The conveying part is equipped with a telescopic frame, which can be stretched back and forth to meet the requirements of different distances for loading and feeding positions.

3. Mobile wheels, pneumatic tires and sliding wheels can be installed at the bottom, which can be moved freely according to the material stacking position, and can be pushed in and out of the manual warehouse.

4. It can be equipped with belts of different widths according to the size of the user's conveying volume. The rear of the machine body can be equipped with a guide groove and a baffle to prevent the material from slipping.

The above is the introduction to the liftable mobile belt conveyor, I hope it can help you.

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

Here are some customer cases of liftable mobile belt conveyors:

Automotive manufacturing: An automotive manufacturing company needed a conveyor system to transport car parts from the assembly line to the storage area. They required a conveyor that could be easily moved and adjusted to accommodate different sized parts. They opted for a liftable mobile belt conveyor that allowed them to adjust the height and inclination to suit their needs, while also providing the flexibility to move the conveyor to different locations within the facility.

Agriculture: A farming operation needed a conveyor system to transport crops such as fruits and vegetables from the field to the packing area. They required a conveyor that could be easily moved and adjusted to accommodate the varying heights of the produce. They opted for a liftable mobile belt conveyor that allowed them to adjust the height of the conveyor to suit their needs, while also providing the flexibility to move the conveyor to different locations within the farm.

Construction: A construction company needed a conveyor system to transport construction materials such as bricks and concrete blocks from the ground level to the upper floors of a building under construction. They required a conveyor that could be easily moved and adjusted to accommodate the varying heights of the building. They opted for a liftable mobile belt conveyor that allowed them to adjust the height and inclination of the conveyor to suit their needs, while also providing the flexibility to move the conveyor to different locations within the construction site.

Recycling: A recycling facility needed a conveyor system to transport materials such as paper and plastic from the sorting area to the storage area. They required a conveyor that could be easily moved and adjusted to accommodate the varying heights of the sorting equipment. They opted for a liftable mobile belt conveyor that allowed them to adjust the height and inclination of the conveyor to suit their needs, while also providing the flexibility to move the conveyor to different locations within the facility.

When choosing a mobile conveyor, there are many factors to consider in order to find the best solution for your needs. Below are some tips on how to choose the right mobile conveyor for your business:

Determine the material you will be conveying. This is important because it will dictate the type of conveyor you need. For example, if you need to transport heavy or bulky materials, you will need a different type of conveyor than if you were transporting smaller items.

Consider the layout of your facility. This includes things like the size and shape of your space, as well as any obstacles that might be in the way. This will help you determine what size and type of mobile conveyor would work best for your business.

Determine your budget. Mobile conveyors can vary greatly in price, so it's important to know how much you're willing to spend before beginning your search.

Compare different models and brands. Once you've determined what you need, take the time to compare different models and brands of mobile conveyors before making your final decision.

Dahan Machinery Co., Ltd. in Xinxiang City, Henan Province has been deeply involved in the conveyor series for many years. Some parts adopt international standards. If there are no relevant parts locally, we provide engineer after-sales service and can be shipped to all major ports. Delivery is within two weeks. Please consult for customization cycle.

Conduct a 48-hour idling test before leaving the factory.

You can take the materials to the factory to test the machine.

We will customize the solution according to your needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.