Specially designed for large output, suitable for safe screening, grading and dust removal of powder and granule

![]()

![]()

Price:$800.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Function: Screening\separation\sorting\sieving

Mesh Size: 10mm-400 mesh (38 microns)

Capacity: 0.12-20 tons/hour

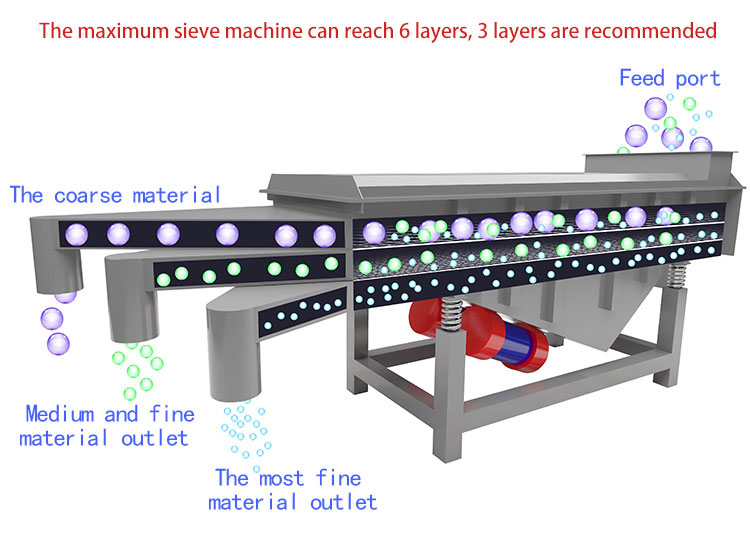

Deck: 1-6

Motor Power: 2x (0.4-0.75) kw

Noise Level: 75db

Material: carbon steel, stainless steel, plastic

Application: sandstone, silicon carbide, rapeseed, peanut shell, almond, limestone, etc. dry powder, particle sieving, grading

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Linear sieve is suitable for the screening of various dry powder materials with particle size of 0.074-5mm, moisture content less than 70%, and no viscosity. The feeding particle size is not more than 10mm. The basic principle of the linear screen is to use the heavy hammer installed at the upper and lower ends of the motor shaft to transmit the rotary motion of the motor to the screen surface, and through the multi-layer screen to produce several specifications of the screen above and below the screen, respectively, from the respective discharge ports discharge. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations.

Stainless Steel Linear Sieve

Made of 304 stainless steel, more durable and rust-proof, suitable for applications where the processing material must be strictly protected from any contamination, where absolute cleanliness and perfect corrosion resistance are required. , such as flour and feed processing, food industry, chemical or pharmaceutical industry.

Air-cooled Linear Sieve

The fan cooling system is added, and the high-temperature materials can be screened after cooling, which effectively reduces the difficulty of screening high-temperature materials, and the screening efficiency and processing capacity have also been greatly improved, saving production costs.

Multi-layer Linear Sieve

The linear vibrating screen installed with 2, 3, 4, 5, 6 layers of screens can realize the continuous classification of 7 kinds of products with different specifications in one operation, and the classification can be carried out after coarse crushing or medium crushing.

Plastic Linear Sieve

It is specially designed to solve the problem of oxidation corrosion after contact with Q235 ordinary carbon steel and SUS304 stainless steel, so as to meet the screening operation of acid, alkali and corrosive materials. The main purpose of use is to remove corrosive powder or particles for sieving and grading.

| odel | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

For example, DZSF515linear sieve represents the screen surface size of the vibrating screen, which is 500mm wide and 1500mm long.

The wider the sieve surface, the thinner the material layer thickness, the greater the output, the longer the sieve surface length, the longer the sieving time, the more opportunities for sieving, and the higher the screening efficiency. Generally, the appropriate width-to-length ratio is 1:2~1:3.

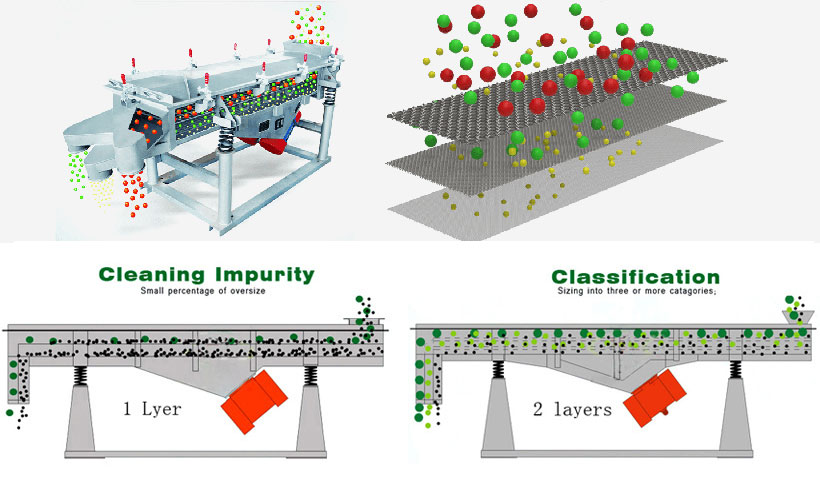

Linear sieves have the ability to screen and convey, and are often used for container filling and safety screening to prevent lumps, oversized products or large particles that can cause problems in subsequent processing or quality control. Another common application is to combine a hopper with a screen to discharge material from the hopper, remove fines and feed the material into the inspection station, thereby improving inspection efficiency.

successfully used with:

Coarse Classification - Classification of bulk materials that do not require extreme dimensional accuracy

Fine Sorting - Provides high accuracy for particle sizes from less than 3 mm to 50 microns

Dust extraction - for removal of undersized dust or particles

Trash removal - Used to remove oversized particles, impurities and other foreign matter etc.

Separation - to remove coarse material from fine material, or for the separation of different particle sizes of the same product.

Linear sieve relies on two reverse motors with the same frequency to make the material jump straight forward on the screen surface, the material smaller than the screen hole diameter falls into the lower layer through the screen, and the material larger than the screen hole size remains on the screen surface and exits from this layer. The material port is discharged, so as to achieve the purpose of screening and grading the material.

1. The screening range is from 20-400 mesh, and the output can reach 20 tons per hour.

2. Equipped with double motors, which are installed vertically to each other to obtain proper vibration flow. The arrangement of the double motors makes the screen frame move and vibrate in a straight line perpendicular to the motor, so that the super large particles have a good forward effect.

3. Materials can be screened into 2, 3, 4, 5, 6 or 7 different grades.

4. Equipped with an adjustable vibration motor, which can help achieve different speeds and vibration levels according to the degree setting.

5. The fully enclosed structure can ensure that there is no dust pollution during the screening process.

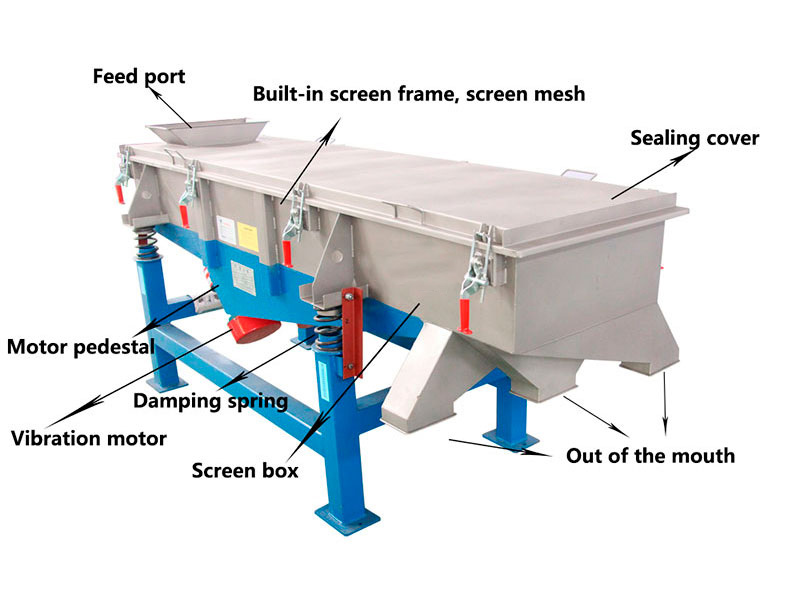

It is mainly composed of screen box, screen mesh, vibration motor, motor pedestal, shock-absorbing spring and bracket.

Screen box: It is the main component of the linear vibrating screen, which is welded by steel plates of various sizes.

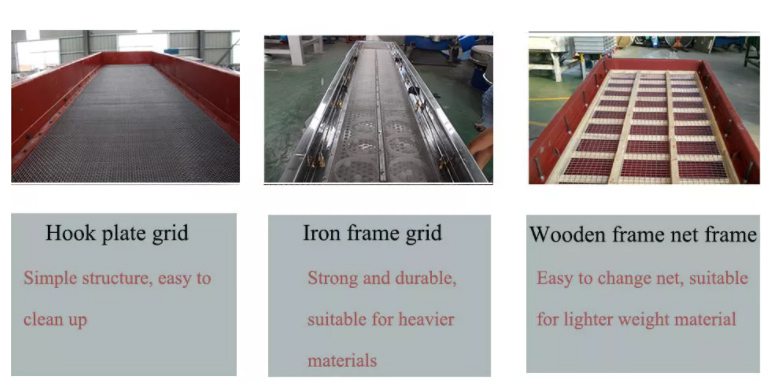

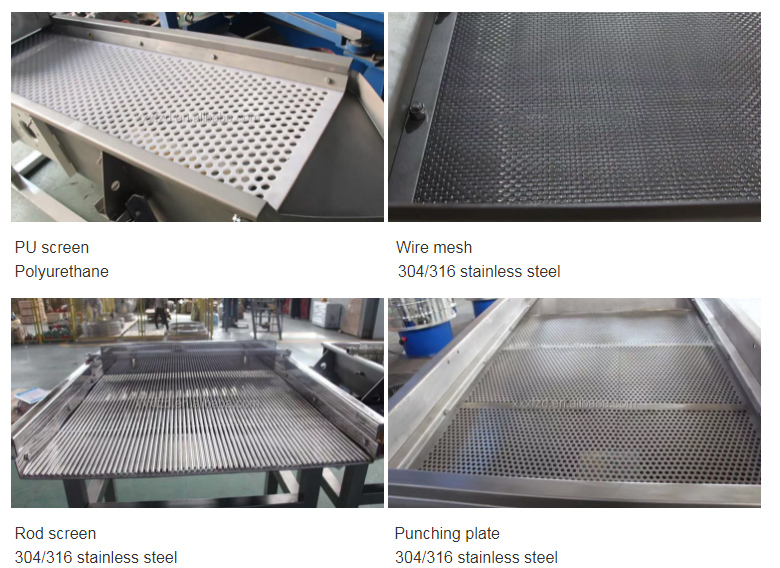

Screen: It is the main working part and has various metal mesh classifications.

Vibration motor: It is the main power part, which drives the work of the entire linear vibrating screen through the work of the vibration motor.

Shock-absorbing spring: used to prevent the stress of the vibration motor from working.

Bracket: the main part, which ensures the overall connection and normal operation of the linear vibrating screen.

Xinxiang Dahan Vibration Machinery Co., Ltd. has a factory area of 10,000 square meters. It has been 15 years since its establishment. Our company has passed ISO and CE certification. The product quality is good. If there is a performance problem within 7 days of the machine being sold, users can choose to repair or replace it for free. machine or exit the machine. The models of linear sieve include DZSF-520, DZSF-525, DZSF-530, DZSF-1020, DZSF-1025, DZSF-1030, etc. Carbon steel and stainless steel can be selected according to the characteristics of the sieved material, and can also be selected according to the purpose of sieving Choose 1~6 layers of screen, if you have special requirements, we can also customize different configurations and designs according to the user's process requirements.

Dahan linear sieve manufacturers provide design selection, test machine with materials, 72-hour free door-to-door delivery, after-sales maintenance and other services, 365-day quality assurance, if you encounter any problems during use, you can consult customer service at any time, we will reply within 24 hours Quick response within 1 hour, if necessary, can arrive at the customer's site within 72 hours for fault maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.