Glitter powder grading linear sieve, commonly known as glitter powder, glitter powder, gold powder, glitter film, pearl powder, etc., is a decorative glitter powder with a wide range of uses, which can be widely used in candle crafts, cosmetics, paint decoration, Spring Festival couplets, calendars, lanterns , wedding, furniture and other occasions, can enhance the visual effect of people.

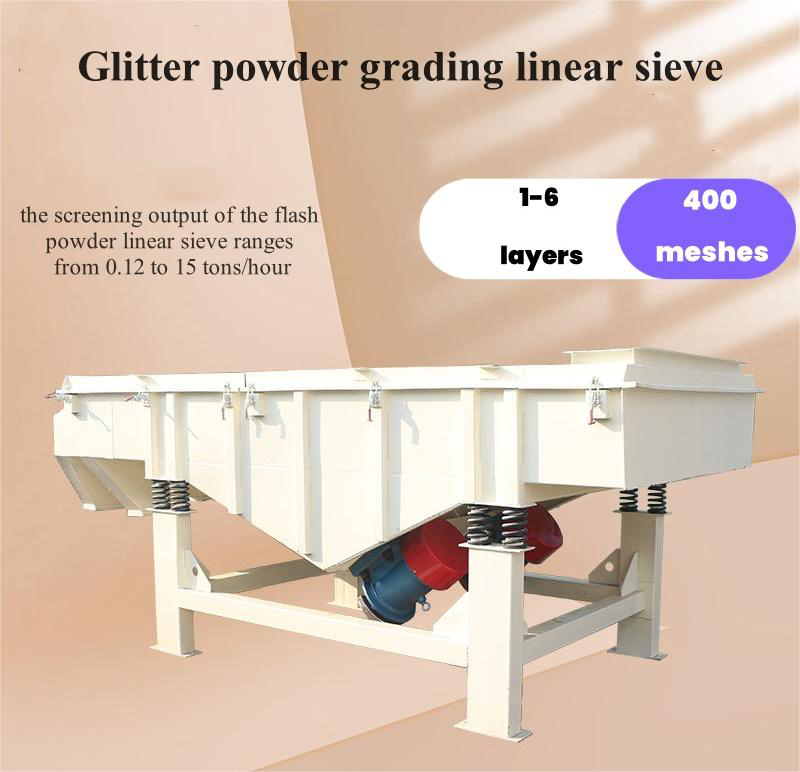

Glitter powder with different fineness specifications has different uses and will show different effects when used. Glitter powder linear sieve can classify glitter powder within 400 meshes, and the design of 1-6 layers of removable sieve box screen can be A linear sieve simultaneously sieves out 2-7 kinds of glitter powder with different mesh numbers.

The glitter powder is poured on the screen of the linear sieve manually or by a silo or feeder, and the exciting force generated by the motor will make the glitter powder spread evenly on the screen surface and move forward.

Spreading evenly on the sieve surface can increase the area of the glitter powder that contacts the screen, and improve the sieving accuracy and sieving efficiency of the glitter powder.

At the same time, due to the small particle size of the glitter powder, the screen mesh diameter is required to be smaller. The mesh of the glitter powder linear sieve is equipped with a supporting mesh frame, and a wooden/metal mesh frame can be selected according to the needs, which can make the mesh mesh more flat and sparkle. The powder passes through the screen faster and the screen has a longer service life and is not easy to be damaged.

The screening capacity output of the flash powder linear sieve is closely related to the size of the flash powder linear sieve. The larger the model, the higher the output. According to different models, the screening output of the flash powder linear sieve ranges from 0.12 to 15 tons/hour. The specific model parameters of the standard linear sieve are as follows (customization is supported):

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

1. According to the characteristics of the light and fineness of the flash powder, the linear screen of the flash powder adjusts the high frequency and low amplitude vibration of the motor to avoid flying the flash powder during the screening;

2. The linear screen can be fully sealed to avoid the phenomenon of flash powder flying and wasting during the screening process;

3. The flash powder linear sieve can be used alone, or can be used in conjunction with a feeding device and a packaging machine to achieve assembly line screening and reduce labor costs;

4. It can be designed and installed according to the user's site environment. There are motor installation methods such as up-vibration, side-vibration, and down-vibration. The small flash powder linear screen can also be installed by hanging;

5. The 1-6 layer sieve box screen can screen 2-7 kinds of particle size flash powder, and can be freely disassembled to adjust to the change of production conditions.

As an important equipment in the food processing industry, the glitter powder grading linear sieve provides high-quality production solutions through its efficient screening and classification functions. Dahan manufacturer has different models of equipment to meet your various needs. If you want to know more about glitter powder grading linear sieve, please feel free to contact me at any time!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.