Used in various laboratories for the separation and classification of powders, granules and suspensions

![]()

![]()

Price:$20.00-$3,680.00/Set

Consult now and enjoy a 10% discount

Diameter: 75/100/200/300mm

Mesh size: 5μm-150mm

Screen type: woven mesh (0.02mm-2.36mm) / perforated plate (: 1mm-125mm) / electroforming (75μm-5μm)

Material: Stainless Steel/Nylon/Brass

Weight: 45kg

Application: Accurate screening, filtration and detection of granular and powdery materials in various laboratories

Commitment:

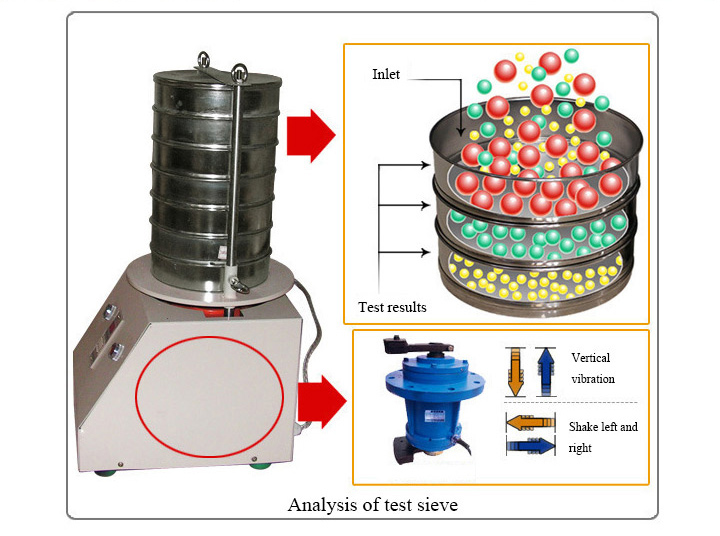

Lab vibrating screen can quickly and efficiently measure solid particle sizes from 125 mm to 20 μm. Special sieves with pore sizes smaller than 20 μm can be used, but it should be understood that the finer the sieve, the more likely certain types of particulate solids will clog or clog the pore size. However, "micro" sieving down to 5 μm is possible using special techniques.

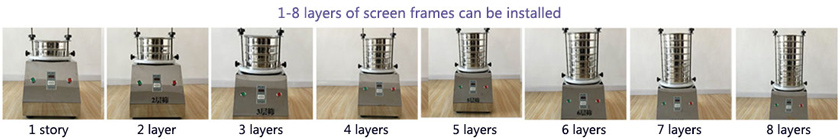

Lab vibrating screens are available in 75mm, 100mm, 200mm, 300mm, and 400mm, among which standard screens between 200mm and 300mm are more common. In addition, stainless steel, nylon, and all-copper screen frames can be selected according to requirements. The sieve machine can be placed up to 8 layers of test sieves (including the bottom sieve), which can accurately separate 2 to 7 particle segments of a particle at the same time, and can be automatically shut down at regular intervals; ensuring the repeatability of the experiment.

Laboratory Test Sieves

It is divided into 300 type and 400 type, mainly to install screen frames with different diameters, and the mesh of the matching screen frames can generally reach 8 mesh to 400 mesh. Used in various laboratories for the separation and classification of powders, granules, and suspensions.

Ultrasonic Lab Vibrating Screen

Equipped with an ultrasonic transducer, it is a laboratory vibrating sieve machine for fine powders with high static electricity, strong adsorption, high density, and light specific gravity. It sieves as fine as 20 microns without clogging the screen.

Electric Sieve Shaker

The electromagnetic vibrator is used as the vibration source, and the vibration frequency reaches 3000 times/min, which improves the screening efficiency of fine materials, and the dry screen can screen to 20um (635 mesh)..

Rotap Sieve Shaker

It has dual movements of slapping and reciprocating, and can control the screening time at regular intervals. It is suitable for high-intensity and high-frequency repeated use in the production and grading process of diamond micropowder and superhard material industries.

| No. | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | s | 1-7 |

| 3 | Number of revolution | Timed/min | 290±6 |

| 4 | tapping | Timed/min | 1-4 |

| 5 | Tapping height | KN | 38±6 |

| 6 | Levelness of the base | mm/min | ≤0.6 |

| 7 | Motor powder | KW | 0.37 |

| 8 | Powder supply | V | 380,220 |

| 9 | Outside dimension | LWH | 433*432*785 |

| 10 | Rotation distance | mm | 25 |

Lab vibrating screen is mainly used in the laboratory to classify and determine the particle size of powders, bulk particles and suspensions. The samples of different sizes are separated through sieves of different sizes, which can quickly and effectively measure the size of solid particles from 125 mm to 20 μm. Stackable 8-layer screen frame (including screen bottom).

Mesh sizes from 20 µm to 125 mm

In the inspection process, the screening accuracy is accurate and the screening efficiency is high, which can quickly and effectively measure the size of solid particles from 125 mm to 20 μm.

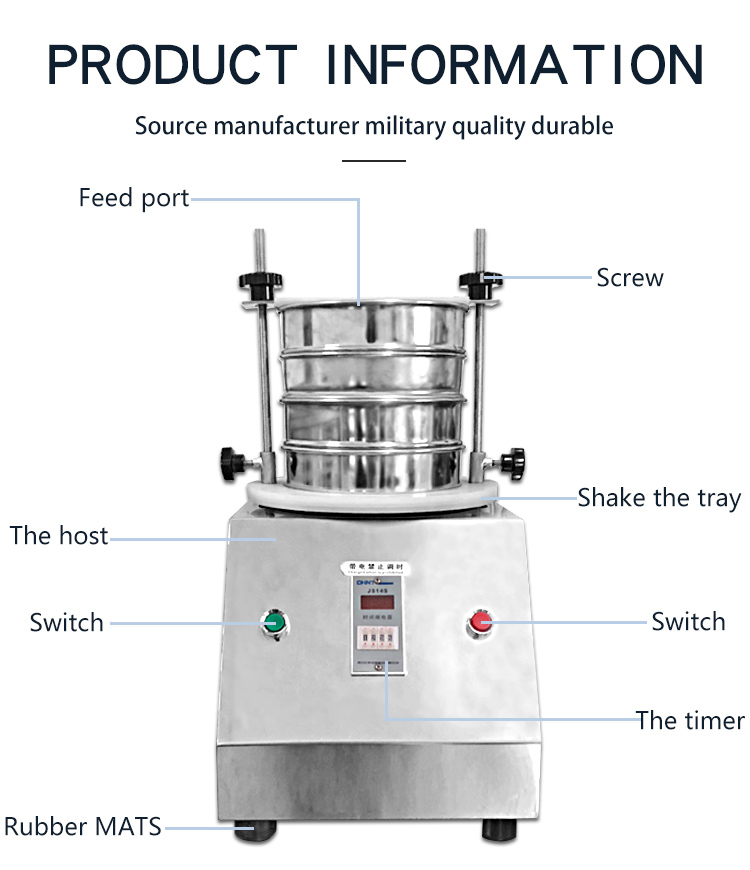

SUS304 stainless steel

The test screen case and vibration plate are made of high-quality SUS304 stainless steel, which is resistant to corrosion, high temperature, not easy to rust, and non-magnetic.

Automatic timer shutdown

Different working hours can be realized through time relay, which can be set from 0 to 99 minutes to reduce inspection errors, ensure the consistency of sample analysis data, and make standard judgments on product quality.

Install the multi-layer test sieve

8 test sieves (including sieve bottoms) can be installed, and a product can be accurately separated into 2-7 particle segments at the same time.

Screen: The screen is the most technical part of the lab vibrating screen. The most commonly used mesh type is stainless steel woven wire mesh. Opening sizes are 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: Frames are circular metal rings that hold the mesh in place. Standard frame sizes in the U.S. are 3 inches, 8 inches, and 12 inches. Internationally, 100mm, 200mm and 300mm are standard sizes. The screen frame can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without tipping over.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| round | 200mm | 200mm | 185mm | 25mm, 50mm |

| round | 300mm | 300mm | 275mm | 75mm |

| square | 300mm | 300mm | 75mm | |

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

| Product | Mesh Size | Product | Mesh Size | Product | Mesh Size |

| Soybean | 5 mesh | Yellow worm powder | 12 mesh | Rice | 12 mesh |

| Sesame | 20 mesh | Corn flour | 30 mesh | Pharmaceutical powder | 50 mesh |

| Flour | 50 mesh | Notoginseng powder | 80 mesh | Seasoning | 60 mesh |

| Pearl powder | 150 mesh | Cereals | 0.025mm-3mm | Iron powder | 270 mesh |

| Plastic particles | 5mm | Resin | 2mm | Graphite powder | 500 mesh |

| Aggregate | 75μm | Aluminum oxide | 100μm | Chemical powder | 150μm |

1. The equipment should be placed horizontally, confirm that the power supply and the nameplate requirements are in line with the requirements, and ensure that the grounding; pay attention to the vibration part can not be in contact with other objects; check whether the bolts of each part are locked.

2. Determine the standard screen frame to be selected according to the tested materials and the corresponding standards.

3. Stack the screen frames on the vibrating plate of the lab vibrating screen from the bottom to the top according to the aperture from small to large.

4. Put the material to be tested into the standard screen frame at the upper end, cover the upper cover of the standard screen, adjust the height of the adjusting rod according to the total height of the standard screen frame, and then use the pressure plate and the lock nut to position and press the standard screen frame ( Note: The force on both sides should be the same).

5. Set the running time on the timer according to the nature of the material and the feeding amount, then turn on the power switch, and the standard sieve will start to work.

6. After the work stops, unscrew the lock nut, remove the pressing plate, and carefully remove the standard screen frame.

7. Cut off the power.

Dahan Machinery mainly produces standard sieves, standard soil sieves, standard pharmacopoeia sieves, standard vibrating sieves, ultrasonic test sieves, magnetic suspension test sieves and other lab vibrating screens, which can be used in metallurgy, chemical industry, medicine, powder, building materials, national defense, geology It is also commonly used in the screening, filtration and detection of the particle size structure, liquid solid content and foreign matter content of granular and powdery materials by scientific research and production, laboratories, quality inspection rooms and laboratories of colleges and universities in other departments. For ordinary abrasive particle size composition inspection and superhard material production grading and other fields.

The manufacturer promises: Standard parts are in stock, 7 working days for special customization, free shipping from the manufacturer, and quality problems within 30 days, users can choose free maintenance or replacement, one-year warranty, and lifetime warranty.

Address: China,Yanjin county forest park gate to the west 1000 meters north road.