It is applied to the classification, screening, analysis and detection of various laboratory samples, and can also be used to analyze the fineness and sundry content of slurry materials

ISO3310-1: 1990 R20/3, R20, R40/3

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

Produced in strict accordance with GB6003.1-1997 or GB6003.2-1997

Diameter: 75/100/200/300mm

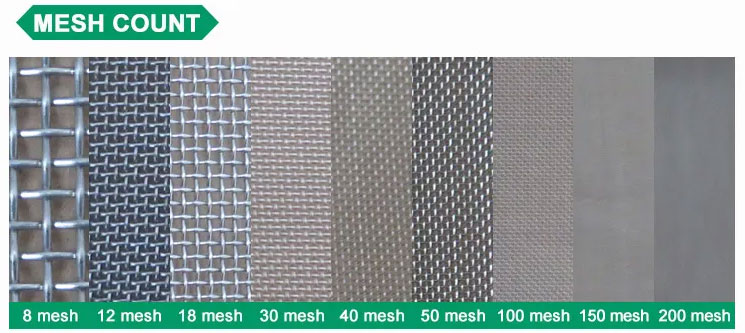

Mesh size: 5μm-150mm

Screen type: woven mesh (0.02mm-2.36mm) / perforated plate (: 1mm-125mm) / electroforming (75μm-5μm)

Material: stainless steel/nylon/, brass

Application: used for precise screening, filtration and detection of the particle size structure, liquid solid content and sundries of granular and powdery materials in laboratories, quality inspection rooms and laboratories of colleges and universities

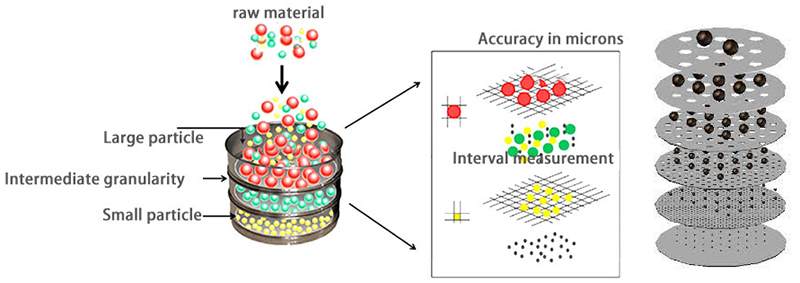

Lab sieve is a device used to separate and classify particles of different sizes by passing them through a mesh or perforated surface, usually used in laboratories for particle size analysis and quality control testing of materials, sieves are usually made of fixed mesh or sieve Composed of a frame and a disc that collects material passing through the sieve, the mesh or sieve is selected according to the size range of the particles to be measured, ranging from 125mm to 20μm.

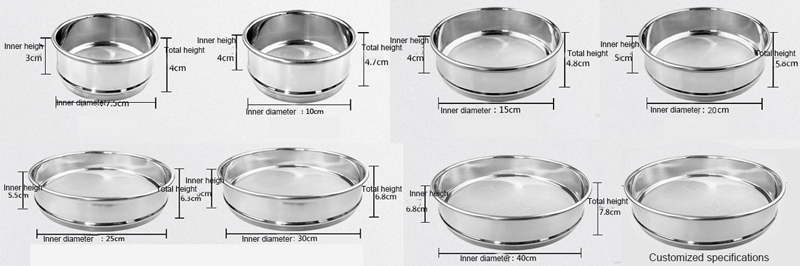

Lab sieve diameters include 75mm, 100mm, 200mm, 300mm, 400mm, and are usually made of high-quality materials such as stainless steel or brass to ensure durability and long-lasting performance. They are available in a variety of sizes and meshes, depending on the specific application and size range of the particles being measured.

Lab sieve is used to separate and classify particles based on their size. Its primary functions include:

Particle Size Analysis: Determines the size distribution of granular materials, powders, or other substances.

Quality Control: Ensures that materials meet specific size specifications for various applications in industries like pharmaceuticals, food, and construction.

Material Characterization: Helps in understanding the physical properties of materials, which can affect their behavior in processes such as mixing, flow, and compaction.

Research and Development: Assists in the development of new materials or formulations by analyzing how particle size affects performance.

Sample Preparation: Prepares samples for further analysis by ensuring uniformity in particle size.

Lab sieves are categorized based on their mesh material, construction, and intended use. Here are some common types:

Based on Mesh Material:

Wire Mesh Sieves: The most common type, constructed with woven wire mesh. They offer excellent particle separation and are suitable for a wide range of applications.

Perforated Plate Sieves: Feature perforated plates with holes of specific sizes. They are typically used for larger particles and offer durability in harsh environments.

Electroformed Sieves: Made by electroplating metal onto a substrate to create a precise mesh pattern. They are highly accurate and ideal for fine particle analysis.

| Types | Materials | Aperture range | Hole shape | Plate thickness/mesh thickness | Diameter | Features |

| Wire Mesh Sieves | Stainless steel, carbon steel, brass | 0.1 mm to 10 mm | Round | 0.1 mm to 1 mm | 200 mm、300 mm、450 mm | Corrosion-resistant, high temperature-resistant, easy to clean |

| Perforated Plate Sieves | Stainless steel, aluminum, plastic | 1 mm to 25 mm | Round, square, rectangular | 1 mm to 5 mm | 200 mm、300 mm、450 mm | High strength, wear-resistant, suitable for heavy materials |

| Electroformed Sieves | Nickel, copper | 0.1 mm or less | Round | 0.02 mm to 0.1 mm | 100 mm、200 mm | High precision, high strength, suitable for fine powders |

Based on Construction:

Single-Sieve: A single sieve with a specific mesh size.

Lab Sieve Set: A stack of sieves with decreasing mesh sizes, used for analyzing a sample over a wide range of particle sizes.

Micro Sieve: Designed for ultra-fine particles, often with mesh sizes below 100 microns.

Based on Intended Use:

Soil Sieves: Used for analyzing soil texture and particle size distribution.200mm(11pcs/set+bottom cover), sizes 0.074mm, 0.25mm, 0.5mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 13mm, 20mm, 40mm, 60mm.

Pharmaceutical Sieves: Designed for powder and granule analysis in the pharmaceutical industry.200x50mm(9pcs/set), specifications are 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh. Specification: 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh

Plastic frame nylon sampling sieve: mainly used in soil testing and fertilizer application, 200x50mm (19pcs/set+bottom cover), with specifications of 14, 20, 30, 40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220, 240, 250, 260, 280, 300 mesh.

Abrasive lab sieve: used for the production, inspection and quality control of abrasive. φ200x50mm (28pcs/set), specifications are 4.75, 4, 3.35, 2.8, 2.36, 2, 1.7, 1.4, 1.18, 1, 0.85, 0.71, 0.6, 0.5, 0.425, 0.355, 0.3, 0.25, 0.212, 0.18, 0.15, 0.125, 0.106, 0.09, 0.075mm.

Sand Sieves: Separate the aggregate of sand and gravel particles with different particle sizes, Ф200x50 (8 only/set), specifications have iron plate round hole 10, 5mm, square hole copper mesh 2.5, 1.25, 0.63, 0.315, 0.16, 0.08mm.

Working principle of lab sieve is to place mixed particles or powder samples on the sieve through the pore size of the sieve, and then mechanically vibrate or manually shake the sieve, so that the particles are separated through the sieve holes according to size, and the smaller particles pass through the sieve. The larger particles are blocked on the screen to achieve separation and screening of particles, thereby achieving the purpose of classifying particles of different sizes.

Accurate Particle Size Analysis

It provides an accurate and precise method for determining the particle size distribution of materials. By passing material through a series of sieves with progressively smaller mesh sizes, particle size can be precisely measured and quantified.

Quality control test

An important tool for quality control testing, enabling manufacturers to ensure that materials meet specific dimensional and quality specifications.

Cost-effective

A cost-effective solution for particle size analysis and quality control testing, providing accurate results without expensive equipment or complicated procedures.

Versatility

Is a versatile tool for a wide variety of materials including powders, granules and other solid materials.

Consistency

Lab sieve provides consistent and reliable results, ensuring a consistent particle size distribution of material from batch to batch.

Durability

Usually made of high-quality materials such as stainless steel or brass, ensuring durability and long-lasting performance.

Lab Sieve Sizes

Lab sieves are available in a variety of sizes, usually specified by the diameter of the sieve frame and the size of the mesh or screen. Common laboratory sieve sizes include:

1. 3" (75 mm) diameter screens with mesh sizes ranging from 4 mesh (4.75 mm) to 500 mesh (0.025 mm)

2. 8" (200mm) diameter screens with mesh sizes ranging from 4 mesh (4.75mm) to 500 mesh (0.025mm)

3. 12" (300mm) diameter screens with mesh sizes ranging from 4 mesh (4.75mm) to 500 mesh (0.025mm)

4. 18" (500mm) diameter screens with mesh sizes ranging from 4 mesh (4.75mm) to 325 mesh (0.045mm)

5. 24" (600mm) diameter screens with mesh sizes ranging from 4 mesh (4.75mm) to 325 mesh (0.045mm)

The mesh or sieve size of the lab sieve depends on the specific application and the size range of the particles being measured. In general, use a larger mesh size for larger particles and a smaller mesh size for smaller particles.

The below table shows the detailed data of different models of lab sieves use stainless steel 304 test sieves for your reference.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

The standard screen size as follow

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.36 | 15 | 70# | 0.212 |

| 2 | 10# | 2 | 16 | 80# | 0.18 |

| 3 | 12# | 1.7 | 17 | 100# | 0.15 |

| 4 | 14# | 1.4 | 18 | 120# | 0.125 |

| 5 | 16# | 1.18 | 19 | 140# | 0.106 |

| 6 | 18# | 1 | 20 | 170# | 0.09 |

| 7 | 20# | 0.85 | 21 | 200# | 0.075 |

| 8 | 25# | 0.71 | 22 | 230# | 0.063 |

| 9 | 30# | 0.6 | 23 | 270# | 0.053 |

| 10 | 35# | 0.5 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.3 | 27 | >500# | <0.028 |

| 14 | 60# | 0.25 |

Lab sieve shakers are devices used to vibrate or agitate sieves during particle size analysis. This helps to ensure that the particles are evenly distributed across the sieve, allowing for accurate and precise results. Some common lab sieve shakers include:

| Category | DH-300T lab sieve shaker | Ultrasonic lab sieve shaker | Electromagnetic lab sieve shaker | Rotap sieve shaker |

| Image |  |

|

|

|

| Application | Used in laboratories, universities and other scientific research institutions for particle size detection, particle size analysis, and debris content analysis | Suitable for high static electricity, strong adsorption, high density, light specific gravity fine powder | Dry or wet sieving or micro-precision sieving for quantitative particle size analysis of various solids and suspensions. | For the production and classification of diamond powder and superhard materials industry |

| Features | The mesh of the matching screen frame can generally reach 8 mesh to 400 mesh, which can divide a product into 7 different particle segments | Sieves down to 20 microns without clogging the screen | The vibrating screen machine with electromagnetic drive has reciprocating suspension movement inside the material, and no material will remain on the screen when sieving. Handling capacity up to 2kg, measuring range 5μm-63mm | Faster unloading with horizontal circular motion and vertical top motion for accurate and consistent particle analysis testing |

Soil Science: Analyzing soil texture and particle size distribution.

Mining and Metallurgy: Grading minerals and ores based on particle size.

Pharmaceutical Industry: Ensuring the consistency and quality of powders and granules.

Food Industry: Evaluating the texture and particle size of food products.

Chemical Engineering: Separating different components of mixtures based on particle size.

| Product | Mesh Size | Product | Mesh Size | Product | Mesh Size |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | Soybean | 4-5 mesh | Green beans | 10 mesh |

| Rice | 12-14 mesh | Rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| Flour | 50-60 mesh | Cereals | 40-50 mesh | Sesame | 22-24 mesh |

The following are some cooperative transaction information of our lab sieves

Spot supply: Dahan is a direct-selling manufacturer, with sufficient product models in stock, and can also support special model designs.

Quality assurance: 30 days for quality problems, return guarantee, and the warranty period of the whole machine is 1 year. If there are quality problems during this period, our factory will provide free maintenance services.

Fast delivery: Standard parts are in stock, and special customization takes 7 working days. The delivery is fast and the cycle is guaranteed.

Service guarantee: 7*24 hours of all-weather service response, a clear reply within 1 hour, and 72 hours of on-site maintenance.

Before choosing a lab sieve, consider these key factors:

Particle size range: Determine the approximate size range of particles you want to analyze, and how accurate do you need the particle size analysis to be?

Material properties: Is the material abrasive, corrosive, or prone to static electricity? Choose a sieve material and mesh type that can withstand these properties.

Sample size and weight: Consider the volume and weight of your sample to ensure the sieve can handle the load.

Sieving method: Manual sieving is suitable for small samples, while mechanical sieving is more effective for larger quantities.

Budget: The price of a sieve depends on the material, mesh size, and manufacturer. Consider your budget constraints.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.