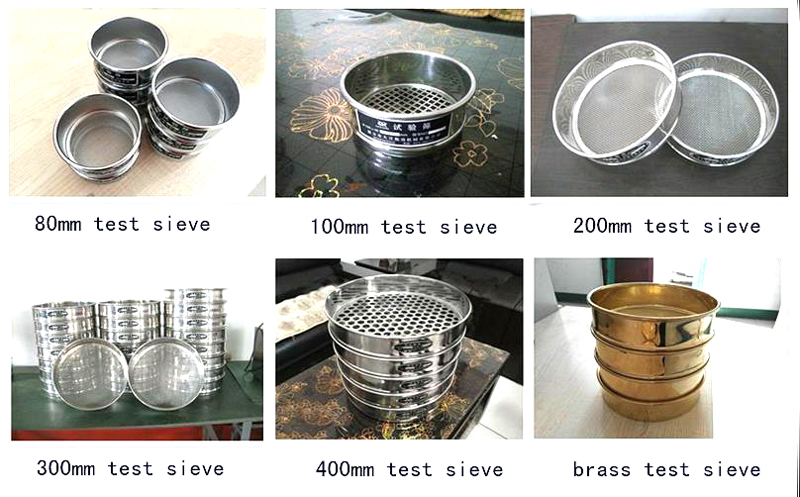

laboratory sieve

laboratory sieve laboratory sieve

laboratory sieve 300mm laboratory sieve

300mm laboratory sieve 200mm laboratory sieve

200mm laboratory sieve laboratory sieve shaker machine

laboratory sieve shaker machine

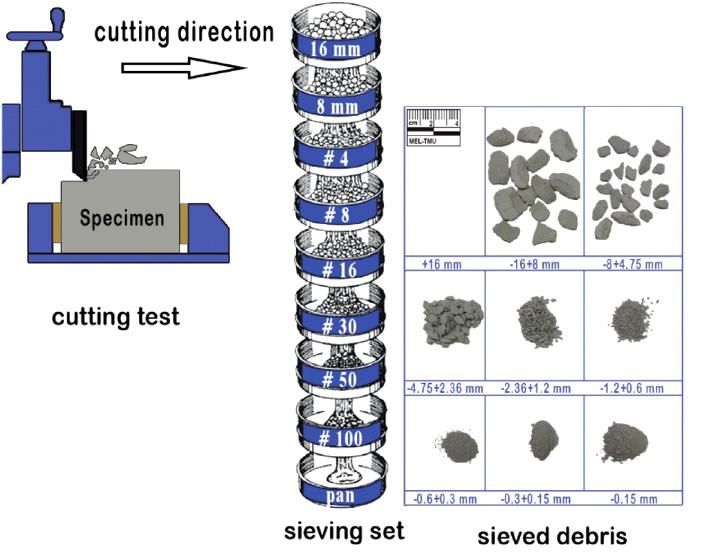

Separation and classification of particles of different sizes according to mesh size

![]()

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm

Screen depth: 32, 50 or 65 mm

Mesh size: 125 mm-20 microns

Braided wire cloth: 30 µm to 11,2 mm (stainless steel)

Circular bore: 0.5 to 125 mm (stainless steel)

Square Bore: 4.0 to 125 mm (Stainless Steel)

Material: stainless steel, brass, nylon

Application: For laboratory particle size analysis and quality control testing of materials such as powders, granules and other solid materials.

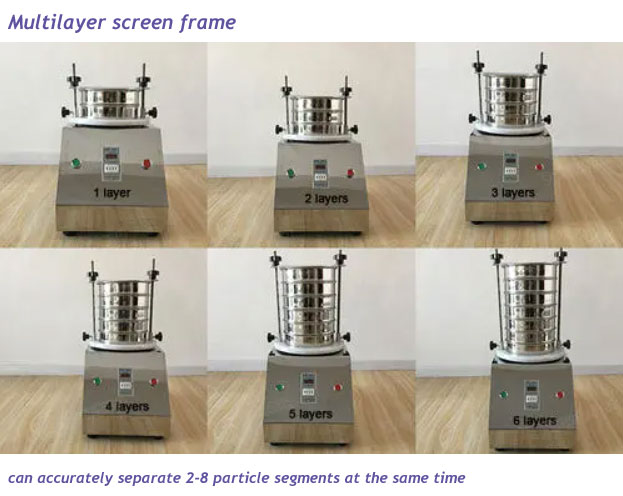

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Laboratory sieve is mainly used in the laboratory to classify and measure powders, bulk particles and suspensions. Different sizes of samples are separated through sieves of different sizes. It can quickly and effectively measure the size of solid particles from 125 mm to 20 microns. Special sieves with pores smaller than 20 μm can be used, but it should be understood that the finer the sieve, the more likely certain types of solid particles will clog or clog the pores. However, "micro" sieving down to 5 μm is possible using special techniques. Laboratory sieve can stack 8 layers of sieve frame (including sieve bottom), which can precisely separate a kind of granular material into 2-7 particle segments at the same time.

Laboratory sieve diameters include 75mm, 100mm, 200mm, 300mm, and the mesh size is from 4mm to 38 microns. When stacked on the sieve shaker, the top test sieve has the largest mesh number and the bottom test sieve has the smallest mesh number.

Laboratory sieves are commonly used equipment in laboratories for grading, screening and analyzing solid particles. According to the different materials of the sieves, laboratory sieves can be divided into the following three types:

Woven wire mesh laboratory sieve: The material is selected from high-quality stainless steel, brass, tin bronze, nickel, molybdenum, etc. The cost is low, the toughness is good, but the relative accuracy is low, and the mesh may be deformed. The accuracy of the mesh can be controlled by expanding and reducing the mesh. The basic size of the mesh is 2.36mm-0.038mm, which conforms to international standards. The screen material is brass, tin bronze, and stainless steel. 2.36um-100um adopts nickel plating processing, which can not only improve the accuracy of the mesh, but also prevent the deformation of the mesh, which is strong, wear-resistant and durable.

Metal perforated plate laboratory sieve: The punching precision is uniform and not easy to deform. It is mainly used for the detection of large particles. There are two types of round holes and square holes. They are mostly used for round hole slag powder collection screens, round hole sandstone screens, etc.

Electroforming laboratory sieve: It is manufactured by electrochemical method, with the highest precision, mesh size range: 500-5um, mesh size absolute tolerance 2-3um, suitable for scientific research institutions, and diamond is widely used.

Each screen material has its own unique characteristics and application range. Choosing the right screen material according to the experimental requirements and material characteristics can improve the accuracy and efficiency of the experiment. The following are common laboratory screen materials for you to choose from:

Stainless steel laboratory screen: It has the advantages of corrosion resistance, easy cleaning, and high temperature resistance. It can screen ores, milk powder, metal powder, etc.

Nylon laboratory screen: It is light and durable and can be used to screen flour, pharmaceutical powder, coffee powder, pigment, etc.

Brass laboratory screen: It has high wear resistance and can screen beans, sugar particles, and gold, silver, and copper ores in mining.

| No. | name | unit | parameter |

| 01 | frame | the number of layer | 1-8 |

| 02 | frame diameter | mm | &200 |

| 03 | sieve size | mm | 0.025-3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 2-500 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | outside dimension | LWH | 350*350*(300+n*5) |

| 08 | power supply | V;HZ | 200;50 |

| 09 | machine weight | kg | 2-500 |

| 10 | vibration motor | power | o.12kw |

Laboratory sieve works by separating particles based on their size. The sample to be analyzed is placed on top of a laboratory sieve, a device with a sieve with holes of a specific size. The sample is then spread evenly on the surface of the screen.

The laboratory sieve is then placed on a mechanical shaker for stirring the sample. The vibrating screen can be set to vibrate at a specific frequency and amplitude to ensure an even distribution of particles across the screen.

As the sample is shaken, smaller particles pass through the holes in the sieve and collect on a tray or container below the sieve. Larger particles remain on top of the screen and cannot pass through the holes.

After shaking is complete, measure and record the amount of material that passes through each sieve. This information is used to calculate the particle size distribution of the sample.

Laboratory sieve is used for particle size analysis, classification and material separation in various industries. They are commonly used in quality control, R&D, and production environments. The following are some specific applications of laboratory sieve:

1. Particle size analysis: used to determine the particle size distribution of the material. This is important for understanding how materials behave in various applications, such as in pharmaceutical formulation, food processing and construction materials.

2. Quality Control: Practical for quality control to ensure that materials meet specific size and quality specifications. This is important to ensure that the final product will perform as expected in its intended application.

3. Separation of materials: Different types of materials can be separated according to the size of the materials. This is important to ensure that the material is of consistent quality and performs as expected in its intended application.

4. Soil analysis: Commonly used in soil analysis to determine the particle size distribution of soil samples. This information is important for understanding soil properties and selecting soil amendments suitable for agricultural applications.

5. Powder Processing: Used in powder processing applications to ensure powders are of consistent size and quality. This is important to ensure that the final product will perform as expected in its intended application.

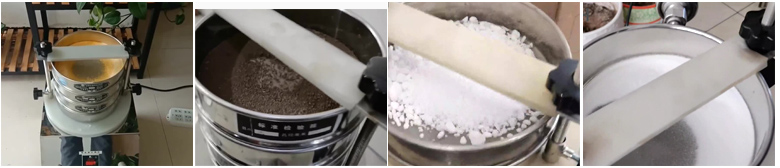

Laboratory sieve for medicinal powder

Laboratory sieve for soy

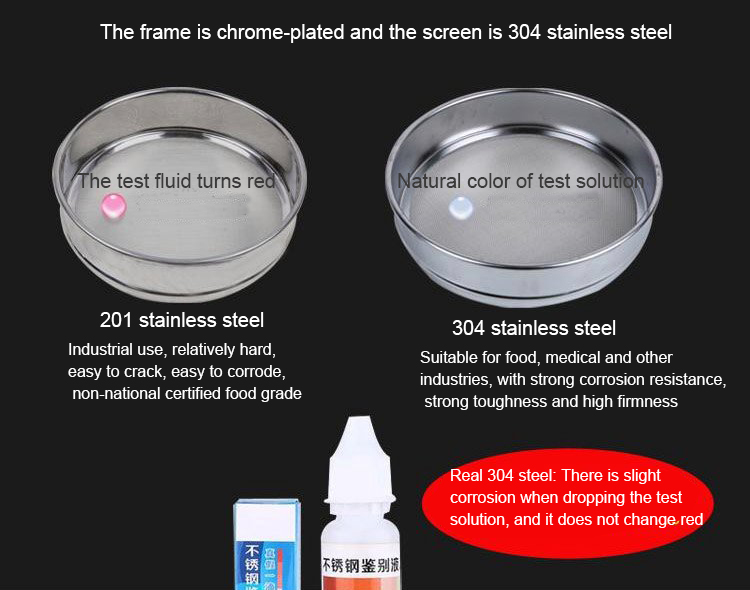

SUS304 stainless steel material

The screen frame is made of SUS304 stainless steel by stretching and polishing, with a wall thickness of 0.6mm, uniform gloss, strong and durable, and non-magnetic.

Precise sieving

It is produced according to the national standard GB/T6003.1-1997, which can quickly and efficiently measure the size of solid particles from 125 mm to 20 μm, which can be sieved to 5 μm using special techniques.

Timing function

It can be equipped with an automatic control timer, which can be set for 1-99 minutes, ensure the consistency of the experiment.

Multi-layer Testing

Suitable for 200mm, 300mm, 400mm diameter laboratory screens, stack up to 8 or 16 standard 200mm test sieves.

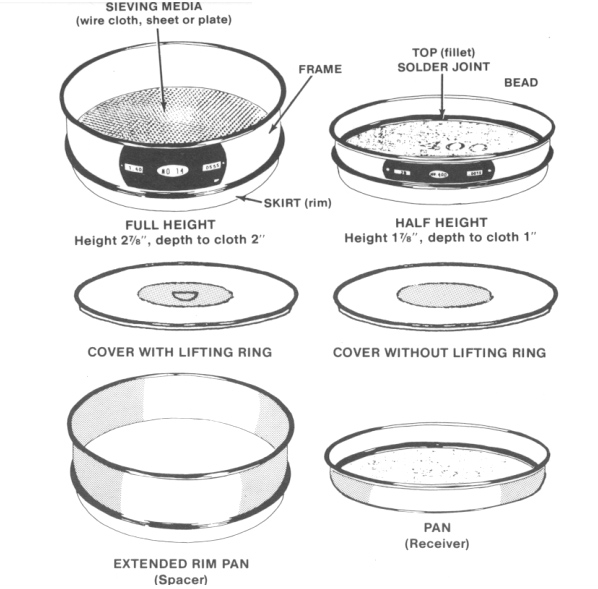

A laboratory sieve usually consists of a circular frame made of metal or plastic with a mesh screen spanning the frame. Screens are constructed of materials such as stainless steel or brass and have a specific pore size and distribution selected based on the application and desired particle size range.

Mesh screens are usually held in place by tensioning devices such as clamps or screws. This tensioning device ensures that the mesh screen is stretched evenly across the frame and will not sag or warp during use.

Laboratory sieves may also have lids or lids to prevent spillage of samples during analysis. The lid may have vents or openings to allow air flow and prevent compression of the sample during analysis.

Laboratory sieves are available in a variety of sizes and mesh sizes and can be designed for use with specific types of mechanical shakers or vibrating devices. The specific size and type of sieve used will depend on the material being analyzed and the desired particle size range.

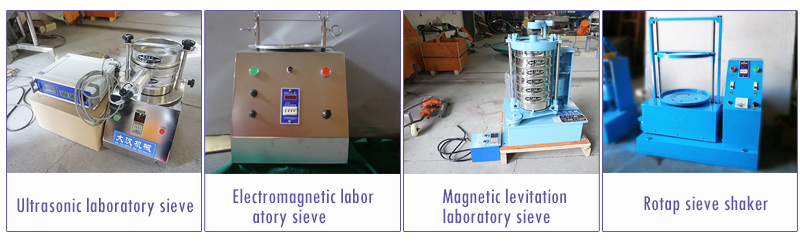

Laboratory sieve can be matched with test sieve shaker. The following are several common laboratory test sieve shakers.

Ultrasonic laboratory sieve: an ultrasonic sieving system is added to the conventional model, and the inspection precision is higher and more accurate. It is a commonly used inspection equipment for mesh blockage when the laboratory is doing fine powder sample screening.

Rotap sieve shaker: It has two vibration modes of slapping and reciprocating at the same time. It is fast in feeding and not easy to block. It is suitable for laboratory screening and testing of materials, especially for the production and classification process of diamond micropowder and superhard materials. High strength, large Repeatedly used frequently.

Magnetic levitation laboratory sieve: covers mechanical physical vibration and high-frequency electromagnetic vibration, and integrates three functions-up and down vibration, back and forth reciprocating motion, left and right swing, so that the material generates a reciprocating suspension motion inside, and it is easy to screen any material It will remain on the mesh, and the fineness can be sieved to 5 microns.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 | 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 | 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Laboratory sieves typically have a diameter of either 8 inches (203 mm) or 3 inches (76 mm). The 8-inch diameter is the most common size used in laboratories.

8-inch diameter sieves: These are commonly used for coarse particle size analysis.

12-inch diameter sieves: These are often used for finer particle size analysis compared to the 8-inch sieves.

200 mm diameter sieves: This size is commonly used in European standards for particle size analysis.

300 mm diameter sieves: These larger sieves are used for analyzing larger quantities of material or when larger particle sizes are involved.

| Material | Mesh | Material | Mesh | Material | Mesh |

| Soy | 5 | Yellow Worm Powder | 12 | Rice | 12 |

| Sesame | 20 | Corn Flour | 30 | Powder | 50 |

| Flour | 50 | Notoginseng Powder | 80 | Seasoning | 60 |

| Pearl | 150 | Cereals | 0.025mm-3mm | Iron Powder | 270 |

| Plastic particles | 5mm | Resin | 2mm | Graphite Powder | 500 |

| Aggregate | 75μm | Alumina | 100μm | Chemical Powder | 150μm |

Please strictly follow the steps below when using laboratory sieve:

1. The equipment should be placed horizontally, confirm that the power supply meets the requirements of the nameplate, and ensure that it is grounded; note that the vibrating part cannot be in contact with other objects; check whether the bolts of each part are locked.

2. Determine the standard screen frame to be selected according to the inspected materials and corresponding standards.

3. Stack the standard sieve frames on the vibrating plate of the test sieve machine according to the aperture from small to large, from bottom to top.

4. Put the material to be inspected into the top standard screen frame, cover the top cover of the standard screen, adjust the height of the adjustment rod according to the total height of the standard screen frame, and then use the pressure plate and lock nut to position and tighten the standard screen frame ( Note: The force on both sides should be consistent).

5. Set the running time on the timer according to the nature of the material and the amount of feed, then turn on the power switch, and the standard screen will start to work.

6. After the standard sieve stops working, unscrew the lock nut, remove the pressure plate, and carefully remove the standard sieve frame.

7. Cut off the power supply.

Dahan Machinery mainly produces laboratory sieve screening equipment, which can be used in scientific research and production, laboratories, quality inspection rooms and laboratories of colleges and universities in metallurgy, chemical industry, medicine, powder, building materials, national defense, geology and other departments. Screening, filtration and detection of the particle size structure, liquid solids content and amount of impurities of powdery materials are also commonly used in the fields of inspection of the particle size composition of ordinary abrasives and the production and classification of superhard materials. Support special model design.

30 days of quality problems will be returned, and the warranty period of the whole machine is 1 year. If there are quality problems during this period, our factory will provide maintenance services free of charge. Standard parts are in stock, fast delivery.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.