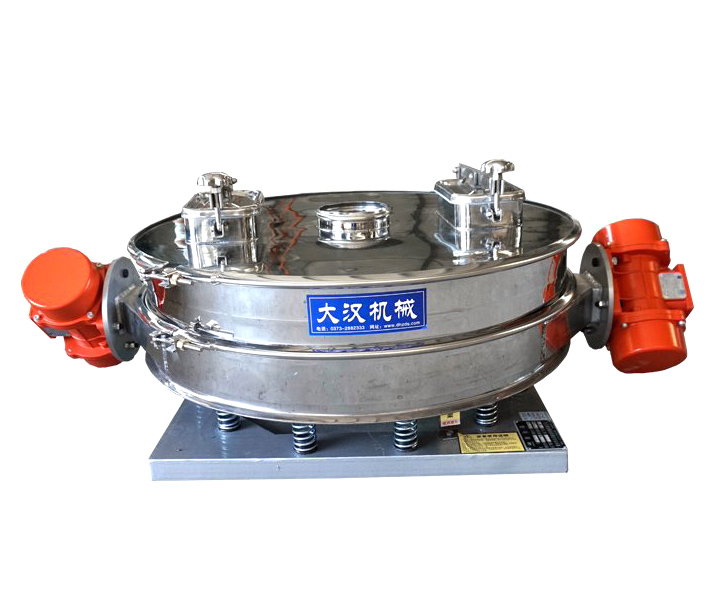

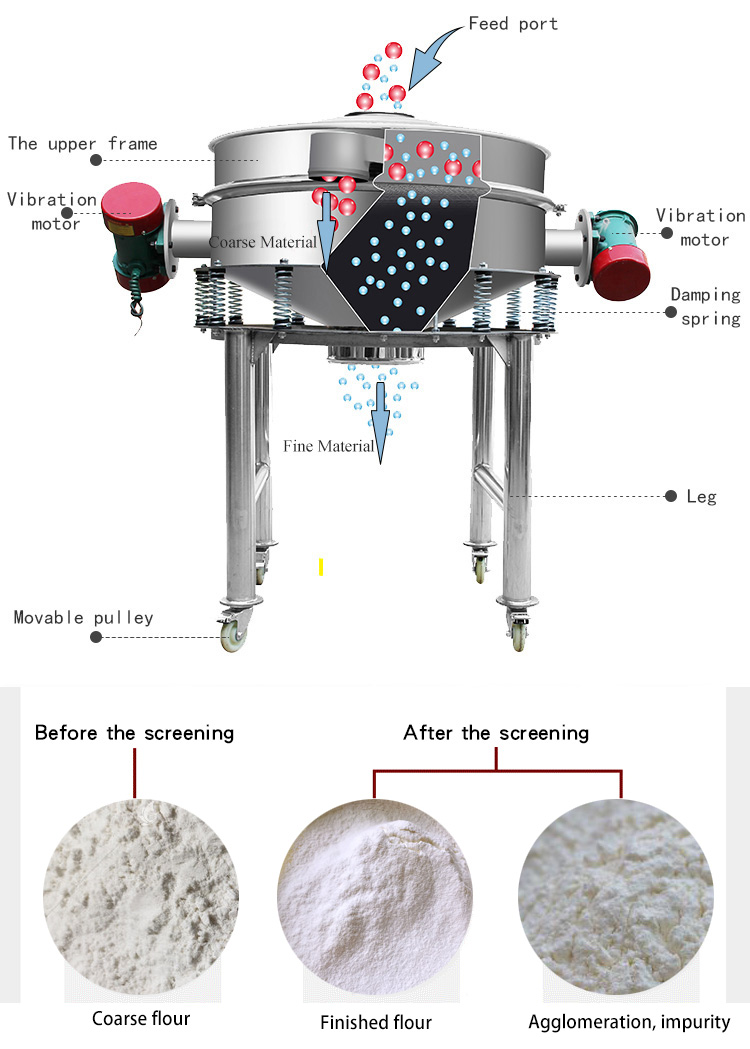

For safe removal of contaminants and lumps from flour

![]()

![]()

![]()

Price:$760.00-$3,090.00/Set

Consult now and enjoy a 10% discount

Particle feed size: 1 micron to 20 mm

Mesh openings: 20 microns to 20 mm

Capacity: 3-30 tons/hour

Power: 2×(0.18-0.75)kW

No. of screen decks: 1 – 2 per machine

Materials: Stainless steel

Surfaces: Electro-polished up to KTS-V 800, otherwise glazed inside and out with a high-grade surface finish.

Application: Used in small artisan bakeries or large industrial flour mills to remove lumps, foreign matter and contaminants, and can screen large quantities of any type of flour, including hard and soft wheat, semolina, corn flour, and more.

Commitment:

Remove agglomerates, foreign bodies and contaminants from flour at high throughput, ensuring the safety, hygiene and quality of the final product.

Commercial flour sifter can effectively remove lint, drum skin, insect eggs, stones, metal impurities, etc. contained in flour, effectively purify flour, and improve the working efficiency of food factories. Commonly used commercial flour sifters are 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh, and 60 mesh. Because flour belongs to the food industry and has relatively high requirements on hygiene, it is necessary to use stainless steel to avoid impurity pollution in the contact part with the material. The seal of the flour sifter is equipped with special silicone material for the food industry to meet the hygiene requirements of the food industry.

Commercial flour sifter is mainly used in integrated processing enterprises such as flour production lines, food processing plants, bakeries, boutique pastry processing enterprises, dried noodles, steamed buns, steamed buns, dumplings and other integrated processing enterprises. The main purpose is to prevent foreign matter from entering the next process and cause food safety problems. According to the different process requirements of the industry, the output is 500-10000 kg/hour, and the screening is about 30 meshes.

| state of flour | Mesh size | Output (kg/h) |

| dry | 20 mesh (0.8mm) | 2000 |

| 30 mesh (0.55mm), 45 mesh (0.18mm) | 1500 | |

| 80 mesh (0.18mm) | 1200 |

Flour passes through screens of different meshes

| Number of meshes (mesh) | 24 | 50 | 60 | 80 | 120 |

| Pass content (g) | 9.72 | 9.31 | 8.92 | 8.64 | 7.43 |

| Fail content (g) | 0.28 | 0.69 | 1.08 | 1.36 | 2.57 |

| By percentage (%) | 97.2 | 93.1 | 89.2 | 86.4 | 74.3 |

Commercial flour sifter for flour removal

Flour production line

Remove latent contaminants

The flour is poured into a flour sifter, where impurities and oversized contaminants are removed before the flour passes through the screen to the rest of the line, ensuring the safety, hygiene and quality of the final product.

Food grade

The sieve is made of SUS304 or 316L stainless steel, mirror-polished, and has a surface finish of 0.1-0.2RA on the inside and outside, designed to meet the stringent engineering and safety standards required by the food industry.

Fast discharge

The inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom enables the material to be discharged directly, reducing the residence time of flour in the sieve, the discharge speed is fast, and the output is 2-5 times that of the ordinary circular sieve.

Closed system

The fully enclosed structure avoids flying powder and eliminates the problem of dust in the air. Manual interaction is free of pollution. It can also be used with a dust-free feeding station to realize the loading, unloading and screening of small or bagged flour to prevent dust pollution.

Easy to clean

It is quick to disassemble and easy to clean, thus increasing productivity and avoiding any chance of cross-contamination between batches.

Compact structure

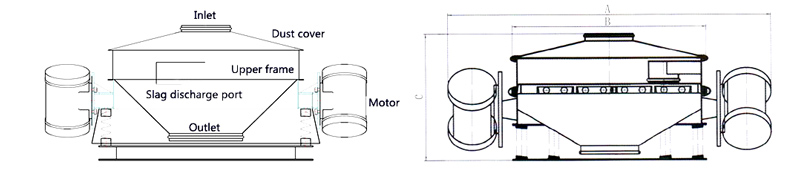

The compact size meets industrial and commercial needs with minimal headroom and floor space, and can fit comfortably into any production line.

| Model | Power (kw) |

Sieving diameter (mm) |

Dimension L*W*H (mm) |

| ZPS-600 | 0.12 | 600 | 740*600*560 |

| ZPS-800 | 0.18 | 800 | 1010*800*600 |

| ZPS-1000 | 0.18 | 1000 | 1200*970*640 |

| ZPS-1200 | 0.25 | 1200 | 1430*1700*700 |

| ZPS-1500 | 0.55 | 1500 | 1780*1470*760 |

Commercial flour sifter can be installed under bulk silo for safe sifting of flour or can be conveyed pneumatically from tanker or rail car receiving operations to check feed after delivery. Dahan Machinery is also specially designed to allow operators to Ability to unload and inspect small or oversized bags of flour in one simple dust-free operation.

For different enterprise scales and processing volumes, Dahan Machinery has designed three targeted solutions.

| Plan A | Plan B | Plan C | |

| Glucose powder |  |

|

|

| Mesh | 20 mesh (aperture: 0.85mm) | 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm) | 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm) OR 40 mesh (aperture: 0.425mm) |

| Capacity | 500-2000kg/hour | 2000-3000 kg/h | 2000-10000 kg/h |

| Configuration | Strainer, vibro sifter | Direct discharge sifter, dust-free feeding station | Fully automatic multi-point feeding system |

| Illustrate | Bag flour → unpacking → manual flour feeding → filter sieve & vibro sifter → turnover bucket → noodle mixer & mixer | Flour in bags→unpacking→manual feeding→direct discharge sifter & dust-free feeding station→vacuum conveying→dough mixer & mixer | Bulk truck → 40 tons buffer storage bin → airflow screening machine & dust-free feeding station → dust removal → weighing system → dough mixer & mixer |

The following is a summary of commercial flour sifter's production of flour with different mesh sizes for your reference:

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr t/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200t |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Rice flour | 0.5 | 100 | DH-1000-1S | 300kg | |

| Corn starch | 0.6 | 40 | DH-1000-1S | 1600kg | |

| Degreased toner | 0.57-0.7 | 24 | DH-1000-1S | 3000kg | |

| Whole milk powder | 0.51-0.8 | 12 | DH-1200-1S | 1600kg |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.