Equipment used to screen and classify crushed stone to obtain the required stone particle size.

![]()

![]()

Price:$500.00 - $6,700.00/Set

Consult now and enjoy a 10% discount

Mesh number: 400 mesh

Feeding particle size: 0.074-10mm

Capacity: 0.12-20 tons/hour

Motor Power: 2*(0.4-3.7)kw

Application: It is used in industries such as construction, highways, railways, water conservancy and chemical industry to screen and classify stones to obtain stones with the required particle size.

Commitment:

Gravel sifter machine is mainly used for grading and screening of gravel, which can be divided into fine gravel (2-10 mm in size), coarse gravel (10-100 mm) and boulder (greater than 100 mm) and other specifications It can also be used to screen the materials crushed by the primary crushing equipment and the secondary crushing equipment, and distinguish the materials that need to be crushed or stone powder, impurities, etc., and can be connected with the main equipment through the belt conveyor Form a closed loop.

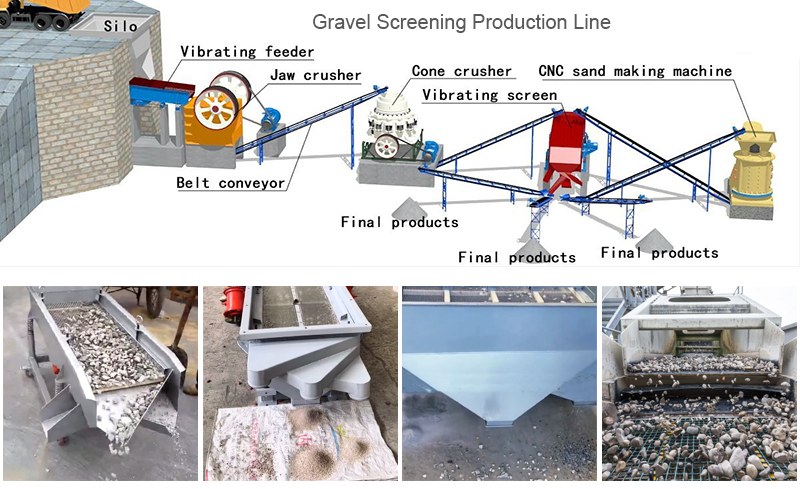

The production process of gravel is generally to feed the 1200mm stone into the vibrating feeder, and the feeder evenly sends it to the impact hammer crusher for a stage of crushing. The particle size of the stone after coarse crushing is about 150mm-300mm Left and right, and then quantitatively sent by the feeder to the secondary crushing process in the shaping hammer crusher, and then graded and screened by the gravel sifter machine, the stones > 40mm obtained from the screening are returned to the hammer crushing equipment for re-crushing; the stones < 40mm are crushed by Driven by the belt conveyor, it is sent to the sand making machine for shaping and crushing.

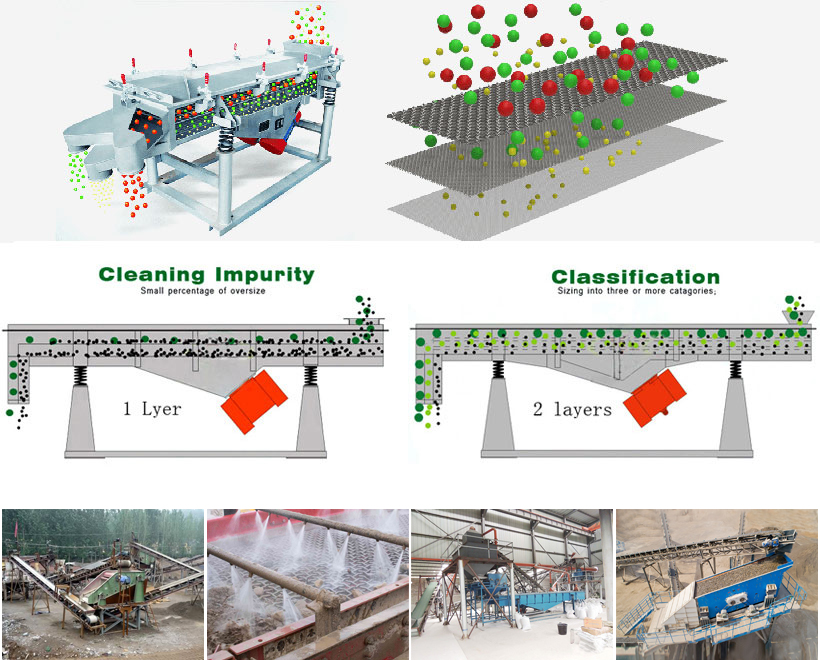

Gravel sifter machine is to separate and sort gravel or other aggregates into different sizes. The working principle of this machine is to use a vibration motor or motor to generate vibration to make the gravel move along the screen surface. As the gravel moves, it will move according to the screen hole The size is divided into different sizes. It mainly has the following functions:

1. Sorting: This machine is used to sort gravel and other aggregates into different sizes, which can be used in various applications such as building foundations, drainage systems or decorative landscaping, by producing aggregates of uniform size, it helps to ensure the final product consistency.

2. Removing impurities: The machine can remove impurities and debris in the gravel, such as rocks, branches and leaves, which will affect the quality and appearance of the final product.

Gravel sifter machines are used in a variety of applications including:

1. Construction: It is often used in construction projects to sort and grade the aggregates of building foundations, roads and other structures.

2. Landscaping: For landscaping projects to sort and grade gravel and other aggregates for decorative landscaping such as paths and gardens.

3. Mining: Used in mining operations to sort and grade ore and other materials.

4. Agriculture: Used in agriculture to sort and grade soil and other agricultural materials.

5. Recycling: Used in recycling operations to sort and grade recycled materials such as crushed concrete and asphalt.

6. Water treatment: Used in water treatment plants to remove sediment and other particles in water.

After a large number of broken materials with different particle sizes and mixed thickness enter the screen surface, only a part of the particles are in contact with the screen surface. Due to the vibration of the screen box, the material layer on the screen is loosened, which further expands the gap between the large particles and the small particles. Particles take the opportunity to pass through the gap and transfer to the lower layer. Because the small particle gap is small, the large particle cannot pass through, so the original chaotically arranged particle group is separated, that is, it is layered according to the particle size, forming a small particle below, and a coarse layer. The particles are arranged regularly, so as to achieve the purpose of screening and sorting materials.

Efficient screening

It can realize multi-layer simultaneous screening, and one material can simultaneously screen 2-6 kinds of materials of different grades.

Large processing capacity

Due to its large screening area, the processing capacity can be as high as 20 tons per hour.

Easy to operate

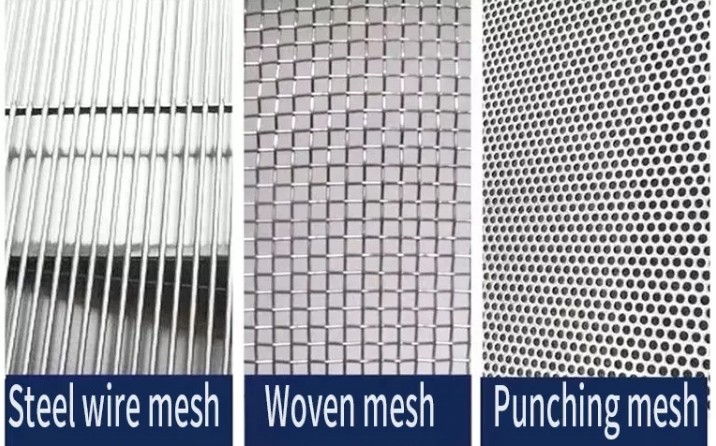

The screen can be replaced according to the requirements of different meshes. It is convenient to change the screen and only takes 3-5 minutes.

Efficient and hygienic

The excitation source with adjustable angle can be used to sieve cleanly; multi-layer design can be used to sieve more.

Automated operation

Gravel sifter machines usually have automated control systems, which are easy to operate, reduce labor costs, and improve production efficiency.

Versatility

Gravel sifter machine is suitable for screening different granular materials and has strong versatility and applicability.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.