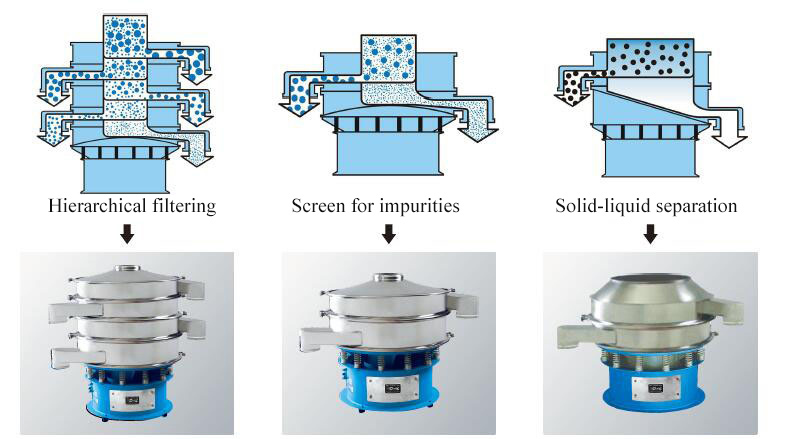

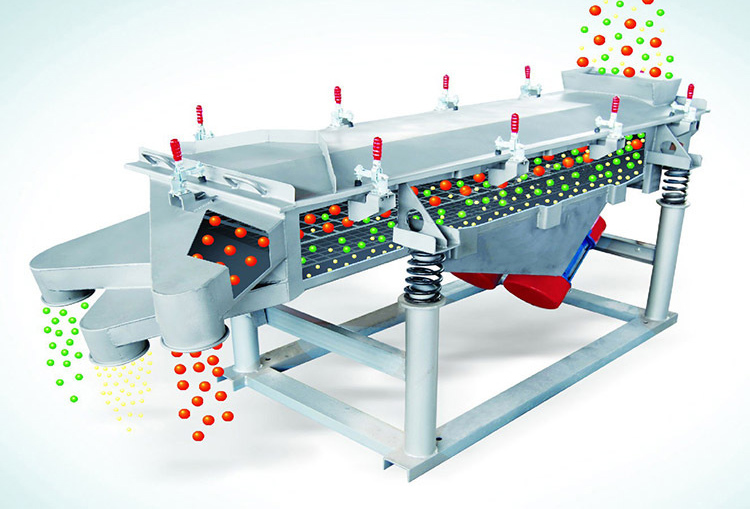

Sifter machine is a common solid screening equipment. It is a device that uses a screen to screen and classify materials. It passes through the aperture of the screen so that materials with larger particle sizes are screened out, while materials with smaller particle sizes pass through the screen to achieve separation and classification of materials. The sifter machine usually consists of a screen box, a screen, a feed port, a discharge port and a driving device.

The working principle of sifter machine is based on the function of screen. The material enters the screen box through the feed port, and the driving device of the screening machine drives the screen box or screen to vibrate or rotate. Under the action of vibration or rotation, the material passes through the aperture of the screen. The larger particles will be screened out, while the smaller particles will pass through the screen to achieve the purpose of separation and classification.

Screen box: The screen box is usually made of welded steel plates, which has high strength and rigidity and can withstand the impact and vibration of materials.

Screen mesh: Screen mesh is usually made of wire mesh or polymer screen plate, with different apertures and mesh shapes to adapt to the screening requirements of different materials.

Inlet and outlet: The inlet and outlet are usually reasonably designed to ensure that materials can smoothly enter and flow out of the screen box to achieve effective screening results.

Driving device: The driving device depends on different types of screening machines. It can be an electric motor, a vibration motor, a gear transmission, etc., and is used to drive the screen box or screen to produce vibration or rotational motion.

Building materials industry: used for screening and grading building materials, such as sand, cement, concrete, etc.

Food industry: used for screening and classifying food raw materials, such as powdered food additives, cereals, powdered sugar, etc.

Pharmaceutical industry: used for screening and grading pharmaceutical raw materials, such as pharmaceutical powders, pills, etc.

Efficient screening: The sifter machine can quickly and effectively screen materials through the action of the screen, improving screening efficiency.

Precise classification: The screen aperture of the sifter machine can be selected as needed to achieve precise classification effects and meet different particle size requirements.

Reliable and stable: The sifter machine has a solid structure and a stable and reliable driving device. It can work continuously for a long time, reduce downtime and improve production efficiency.

Multifunctional application: sifter machine can be adjusted and configured according to the characteristics and screening requirements of different materials, and is suitable for screening and grading of various materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.