Grain bucket elevator is a vertical conveyor system specifically designed for the handling and transportation of grain or other bulk materials. It is commonly used in agricultural and industrial settings, such as grain storage facilities, flour mills, feed mills, and grain processing plants.

1.Material Handling: Grain bucket elevators efficiently move grains and other bulk materials vertically within a processing facility, enabling the seamless transfer of materials between different processing stages.

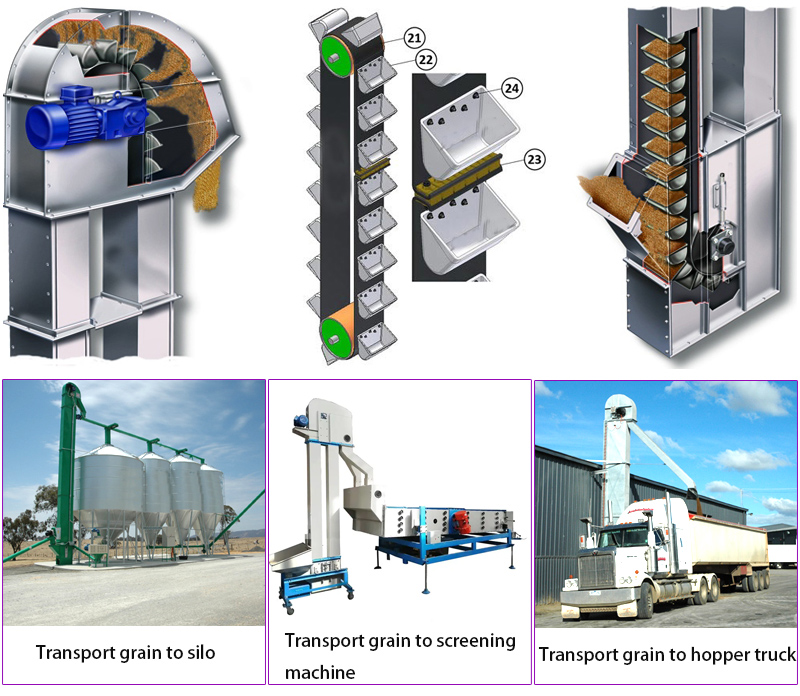

2.Storage and Distribution: These elevators are used to transport grains to storage silos, bins, or processing equipment, facilitating the storage and distribution of grains in a controlled manner.

Grain bucket elevators are mainly used for the following purposes:

1. Lift grain from grain trucks, granaries or other conveying equipment to silos or processing equipment;

2. Upgrade bulk materials such as grain, oil, food, chemicals, and building materials from one process of the production line to another;

3. Lift the bulk materials from the silo to the hopper truck or other conveying equipment.

The application scenarios of grain bucket elevators mainly include the following:

1. Grain processing plant: In grain processing plants, grain bucket elevators are used to lift grain from grain trucks, granaries or other conveying equipment to silos or processing equipment. For example, in wheat processing plants, bucket elevators are used to lift wheat from grain trucks to silos, where it is then processed into flour through cleaning, grinding and other processes.

2. Oil processing plant: In oil processing plants, bucket elevators are used to lift oil from feed trucks, oil depots or other conveying equipment to silos or processing equipment. For example, in soybean oil processing plants, bucket elevators are used to lift soybeans from feed trucks to silos, where they are then processed into soybean oil through processes such as shelling, pressing, and extraction.

3. Food processing plants: In food processing plants, bucket elevators are used to lift food raw materials from trucks, warehouses or other conveying equipment to silos or processing equipment. For example, in a biscuit processing plant, bucket elevators are used to lift flour, sugar, oil and other raw materials from trucks to silos, and then process them into biscuits through mixing, tableting, baking and other processes.

The grain bucket elevator consists of a series of buckets attached to a belt or chain that moves vertically within a casing or housing. The buckets are designed to scoop up the grain from a lower level and carry it upward to a higher level, where it is discharged. The belt or chain is driven by a motor, providing the necessary power for vertical movement.

Bucket Design: The elevator is equipped with buckets attached to a belt or chain that moves materials vertically. These buckets are designed to effectively scoop up and transport grains without spillage.

Vertical Transport: Grain bucket elevators are used for vertical conveying of grains, seeds, pulses, and other bulk materials within grain storage facilities, feed mills, flour mills, and other agricultural processing plants.

Capacity and Speed: These elevators are available in various capacities and can handle a wide range of grain types. They can operate at different speeds to match the processing requirements.

Dust Control: Grain bucket elevators are designed with features to minimize dust generation during material handling, ensuring a cleaner and safer working environment.

Durability: They are typically constructed with durable materials such as galvanized steel or stainless steel to withstand the harsh conditions of grain handling operations.

Safety Features: Grain bucket elevators are equipped with safety features such as guardrails, access doors, and emergency stop systems to ensure the safety of operators and prevent accidents.

Customization Options: Manufacturers offer customization options for grain bucket elevators, allowing for the adaptation of the equipment to specific facility layouts and processing requirements.

In summary, a Grain Bucket Elevator is a vital piece of equipment in the agricultural and food processing industries, facilitating the vertical transport of grains and bulk materials with efficiency, reliability, and safety.

Want to learn more about grain bucket elevators? Don’t forget to scroll down to view our handpicked selection of related products, and click inside to learn more about the various models and features we offer.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.