Efficiently and safely handle bulk fertilizer materials such as granules, powders or pellets.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-100 tons/hour

Lifting height: ≤20 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: Used to lift the raw materials required for fertilizer production (such as nitrogen, phosphorus, and potassium fertilizers) from the ground or storage equipment to the top of the production process such as mixing, grinding, and screening.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Fertilizer bucket elevator is a type of conveying system specifically designed for vertically lifting or elevating various types of fertilizers. It consists of a series of buckets attached to a belt or chain that moves in a continuous loop, allowing the buckets to scoop up fertilizer material at one end and discharge it at a higher elevation at the other end.

The fertilizer bucket is an elevator that can efficiently transport large granular or powdery fertilizer raw materials to the required location, such as mixing equipment, batching machines, packaging equipment or storage warehousing systems. The application of bucket elevators in the fertilizer industry can Improve production efficiency, reduce manual labor, and ensure accurate and reliable transportation of materials.

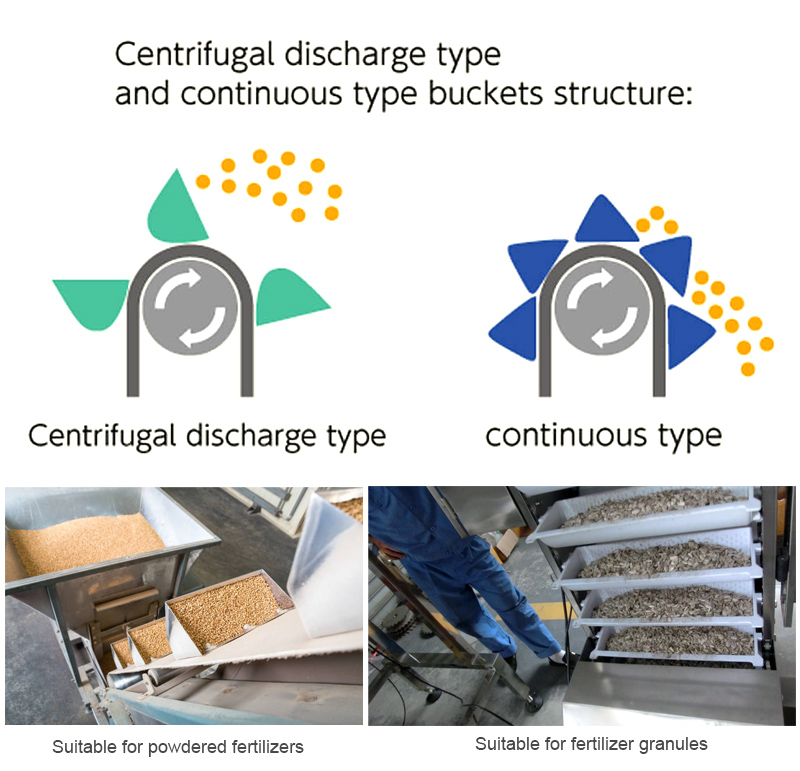

Centrifugal Discharge Bucket Elevators: These elevators use centrifugal force to throw material out of the hopper at the discharge point. They are ideal for handling free-flowing fine or powdered fertilizer materials.

Continuous Discharge Bucket Elevators: These elevators use a stationary plow to scrape material out of a bucket at the discharge point. They are better suited for handling fertilizer granules of various sizes.

Bucket elevators are widely used in the fertilizer industry for vertical transportation and lifting of various types of fertilizer raw materials and finished products. The following are common applications of bucket elevators in the fertilizer industry:

1. Raw material transportation: Bucket elevators can be used to lift raw materials (such as nitrogen, phosphorus, and potassium fertilizers) required in fertilizer production from the ground or storage equipment to the top of production processes such as mixing, grinding, and screening.

2. Mixing and batching: The fertilizer bucket elevator can lift various raw materials into the mixing equipment or batching machine to ensure the accuracy and efficiency of the mixing process.

3. Drying and cooling: It can be used to lift fertilizer particles into a dryer or cooling equipment for necessary processing and conditioning.

4. Finished product packaging and storage: It can efficiently transport finished products to packaging machines or storage bins to facilitate subsequent packaging, storage and sales

The common occasions where bucket elevators transport fertilizers are as follows:

1. Fertilizer factory: In the fertilizer factory, bucket elevators are mainly used to transport raw materials from the raw material warehouse to the production workshop, and to transport finished fertilizers from the production workshop to the finished product warehouse.

2. Fertilizer production line: In the fertilizer production line, bucket elevators are mainly used to transport raw materials, intermediate products and finished fertilizers between different processes.

3. Storage and packaging: Used to vertically lift fertilizers from the storage area to packaging equipment to facilitate packaging and shipping.

4. Fertilizer mixing system: Fertilizers with different components are lifted from different areas to the mixing equipment for mixed production.

5. Fertilizer batching system: used to lift fertilizer powder or granules of different batches for mixing.

6. Fertilizer conveying system: In the fertilizer production line, it is used to connect different production units to achieve continuous conveying and processing of fertilizer.

Vertical Transportation

The bucket elevator allows for the vertical transportation of fertilizers, which is essential for multi-level fertilizer processing plants or storage facilities. It enables the transfer of materials between different floors or levels.

High Capacity

Bucket elevators are capable of handling large volumes of fertilizer materials. They can be designed and sized to meet specific capacity requirements, ensuring smooth and continuous material flow.

Minimal Product Damage

The design of the buckets and the controlled discharge of materials help minimize product damage during transportation. This is crucial for preserving the integrity and quality of the fertilizers.

Flexibility and Customization

Fertilizer bucket elevators can be customized to suit the specific needs of the application. They can be designed to accommodate various types of fertilizers, adjust to different lifting heights, and integrate with other equipment in the fertilizer production line.

Fertilizer bucket elevator drives a lifting mechanism equipped with a bucket-shaped container through a motor-driven chain or belt. The bucket-shaped container moves along the track of the lifting mechanism under the guidance of the chain or belt. When the bucket-shaped container rises along the lifting mechanism, the fertilizer is loaded into the bucket. With the movement of the lifting mechanism, the fertilizer is lifted vertically to the target height, and finally discharged through the discharge port. The entire process realizes vertical transportation of fertilizer.

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

To prevent lumps or caking of fertilizers in bucket elevators, a variety of anti-caking devices are available. These devices help ensure a smooth flow and discharge of fertilizer, reducing the risk of clogging and maintaining product quality. The following are some anti-caking devices commonly used in fertilizer bucket elevators:

1. Vibration device: The vibration device is installed along the bucket elevator to apply vibration to the hopper or elevator structure. These vibrations help to move and break up any compacted fertilizer material, preventing clumping and promoting material flow.

2. Anti-caking lining or coating: Anti-caking lining or coating can be applied to the bucket or other inner surfaces of the bucket elevator. These linings or coatings provide a non-stick surface that resists the sticking of fertilizer particles, minimizes the possibility of clumping and facilitates material flow.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.