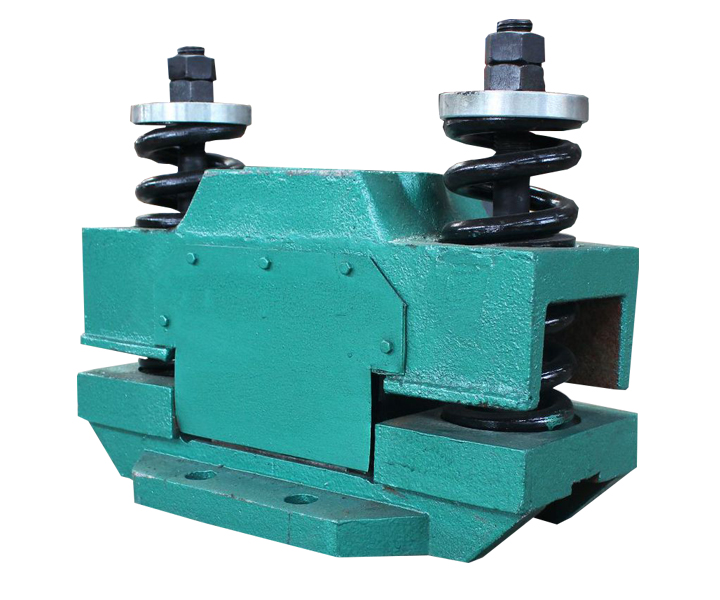

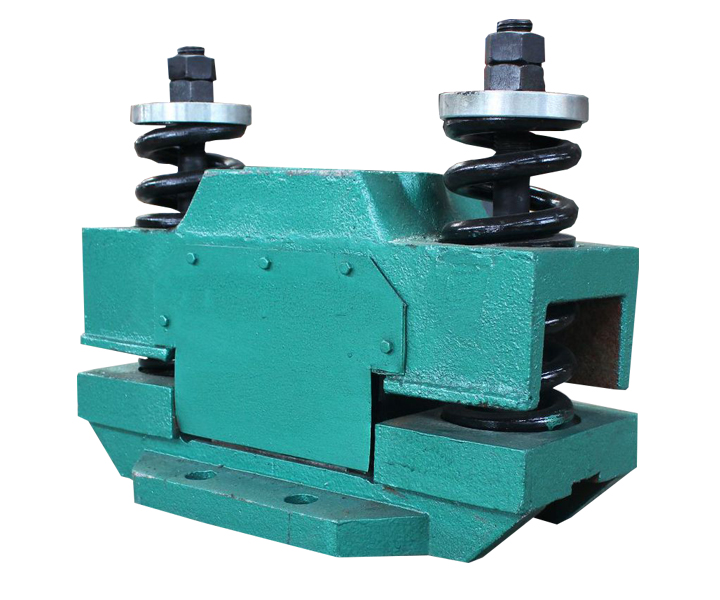

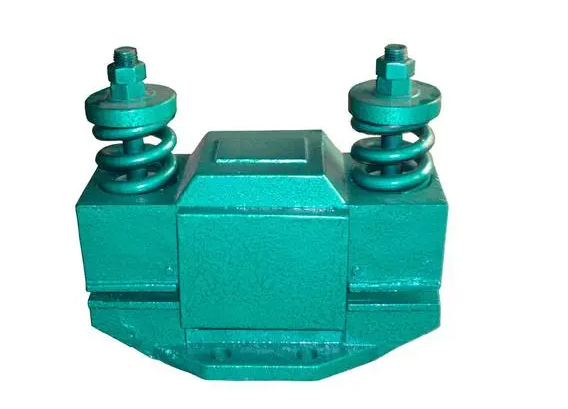

It is a device attached to machinery and equipment to generate exciting force. It is also an important part that uses mechanical vibration. It relies on high-frequency vibration and impact force to eliminate the blockage caused by internal friction, deliquescence, electrification, composition segregation, etc.

![]()

![]()

![]()

Price:$500.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Warehouse wall thickness: 0.6-14mm

Vibration frequency: 3000 times/min

Exciting force: 0.1-10N

Power: 0.008-0.2

Application: mining, metallurgy, chemical industry, building materials, machinery and other industries.

Electromagnetic vibrator relies on high-frequency vibration and impact force to effectively eliminate the blockage and tower arch phenomenon caused by internal friction, deliquescence, electrification, component segregation, etc., so that the material can be smoothly discharged from the silo. Electromagnetic vibrator can ensure stable supply. required equipment. Electromagnetic warehouse wall vibrators have been widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries.

Electromagnetic vibrator is used to prevent and eliminate the phenomenon of "blocking" and "tower arch" caused by internal friction, deliquescence, electrification, component segregation, etc. It can also be used as a vibration source for vibrating feeders, vibrating conveyors, vibrating funnels, vibrating chutes, etc. Widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries.

1. It can be used in inclined discharge chutes to facilitate the easy flow of materials through vibration.

2. It can be used in rectangular or cylindrical silos with central discharge to enable materials to be discharged quickly.

3. In the chemical and pharmaceutical industries, it can effectively disperse agglomerated powders for transportation.

4. It can ensure that the material moves horizontally and evenly in the box without accumulation.

The control principle of the electromagnetic vibrator is half-wave rectification. The electromagnetic coil is powered by alternating current through diode rectification. When the line is connected, the positive half-cycle pulsating DC voltage is applied to the electromagnetic coil, and the effect of the electromagnet is between the vibrating body and the frame. A pulsed electromagnetic force is generated, and the vibrating body is attracted. At this time, the elastic system stores potential energy. In the negative half cycle, the diode does not conduct, and the electromagnetic force disappears. With the help of the potential energy stored in the elastic system, the vibrating body vibrates in the opposite direction. It vibrates back and forth at the frequency of alternating current. The periodic high-frequency vibration of the vibrating body is transmitted to the silo wall through the impact block. The periodic vibration of the silo wall, on the one hand, makes the material out of contact with the silo wall, and on the other hand, makes the material affected by the alternating speed and acceleration, and is placed in the silo wall. Unstable state, so as to effectively overcome the internal friction and focusing force of the material, so that the material can be smoothly discharged from the silo mouth.

1. It has the characteristics of small size, light weight, simple structure, low power consumption and small maintenance.

2. The periodic high-frequency vibration of the vibrating body is transmitted to the silo wall through the "impact block".

3. The periodic vibration of the warehouse wall, on the one hand, makes the material out of contact with the warehouse wall, and on the other hand, makes the material affected by the alternating speed and acceleration. in an unstable state.

Therefore, the internal friction and aggregation force of the material can be effectively suppressed, so that the material can be smoothly discharged from the silo mouth.

5. Low energy consumption, low noise, long life, easy to use and so on.

6. The vibration frequency and amplitude can be selected according to different purposes.

7. According to the requirements of use, the supporting electronic control device can be designed.

| Model | Vibration force (kg) |

Power (KW) |

Voltage (V) |

Current (A) |

vibration frequency( time/min) |

vibration amplitude (mm) |

warehouse wall thickness (mm) |

| CZ10 | 10 | 0.008 | 220 | 0.11 | 3000 | 1.5 | 0.6-0.8 |

| CZ50 | 50 | 0.03 | 220 | 1.1 | 3000 | 1.5 | 1.2-1.6 |

| CZ100 | 100 | 0.06 | 220 | 1.0 | 3000 | 1.5 | 2.5-3.2 |

| CZ250 (CZ200) |

250 | 0.1 | 220 | 1.6 | 3000 | 2 | 1.0-4.0 |

| CZ600 (CZ400) |

600 | 0.15 | 220 | 2.3 | 3000 | 2 | 3.0-8.0 |

| CZ1000 (CZ800 |

1000 | 0.2 | 220 | 3.8 | 3000 | 2 | 6.0-14 |

| CZ1500 | 1500 | 0.45 | 220 | 7.0 | 3000 | 2 | 6.0-14 |

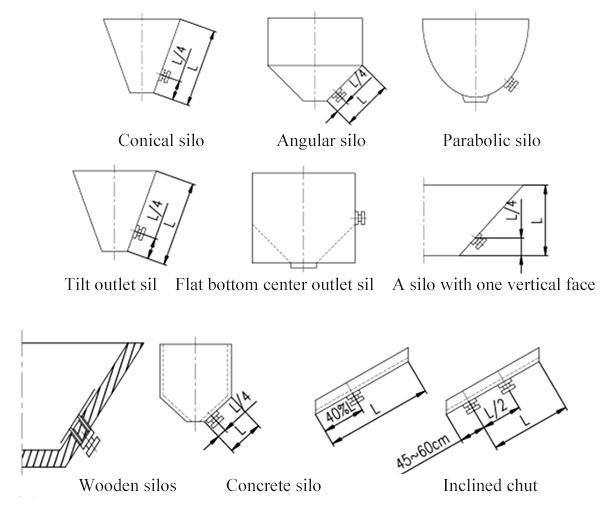

1. All-steel steel silo: It should be welded on the wall of the silo.

2. Full concrete silos and silos with reinforced steel bars: vibrating plates should be laid in the silos, and LZF type anti-blocking devices should be welded on the vibrating plates.

3. The upper part is a concrete silo, and the lower part is a steel hopper: it should be welded on the wall of the dry hopper.

4. The silo for storing pure coarse materials: No matter what the form is, a vibrating plate should be laid in the silo, and the vibrator on the wall of the silo should be welded on the vibrating plate.

5. Chute: The LZF vibrator should be welded on the part of the chute that is easy to stick and block materials.

6. Conical silo: When the diameter of the installation part is greater than 1m, please install two.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.