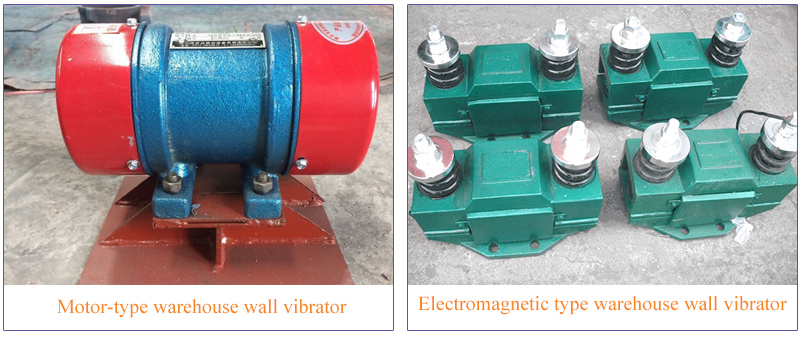

Warehouse wall vibrator

Warehouse wall vibrator Electromagnetic wall vibrator

Electromagnetic wall vibrator Silo Vibrator Motor preventing blockage

Silo Vibrator Motor preventing blockage Explosion proof warehouse wall vibrator

Explosion proof warehouse wall vibrator Vibrator warehouse

Vibrator warehouse

Prevent and eliminate material sticking and buckling in silos, tanks, chutes and tubular passages

![]()

![]()

![]()

Price:$500.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Warehouse wall thickness: 2-40mm

Cone storage capacity: 0.4-200m3

Vibration force: 10-500KN Power: 0.09-3.7KW

Voltage: 220v/380v (customizable voltage)

Work Quota: SI

Insulation class: F Protection class: IP65

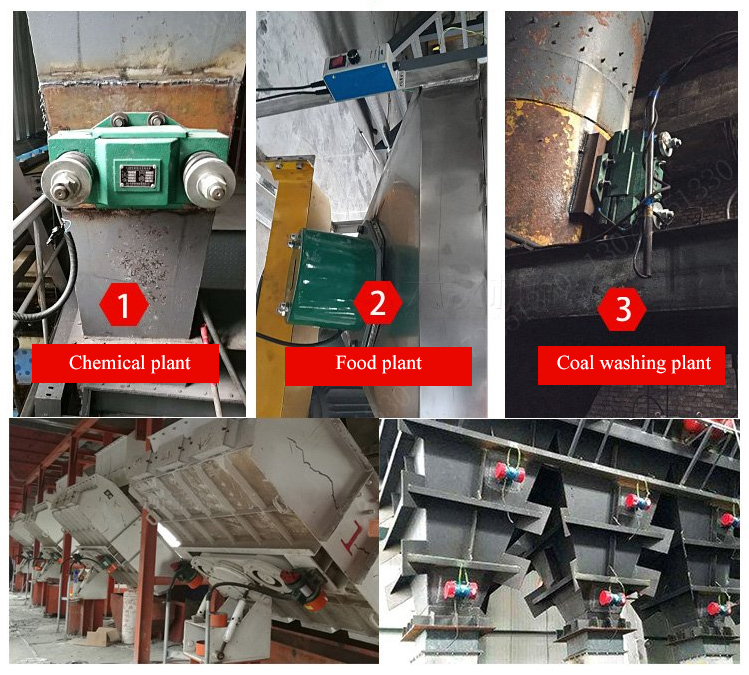

Application: The new type of vibration arch breaking equipment installed on the silo or hopper wall is widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries.

Commitment:

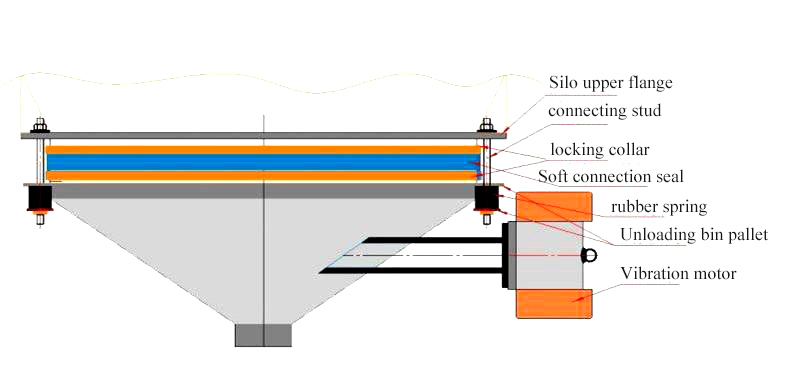

Warehouse Wall Vibrator, also known as wall vibrator, is an anti-blocking device, which uses a vibration motor or an electromagnetic vibrator as the vibration source, and relies on high-frequency vibration and impact force to prevent and eliminate various silos due to the internal friction of materials, The phenomenon of "blocking" and "tower arch" caused by deliquescence, electrification, component segregation, etc., ensures stable feeding of equipment, and can also be used to remove various silo walls and pipelines. Vibration source of machine, vibrating funnel, vibrating chute, etc.

Use effect——material flows smoothly from the silo, tank or hopper

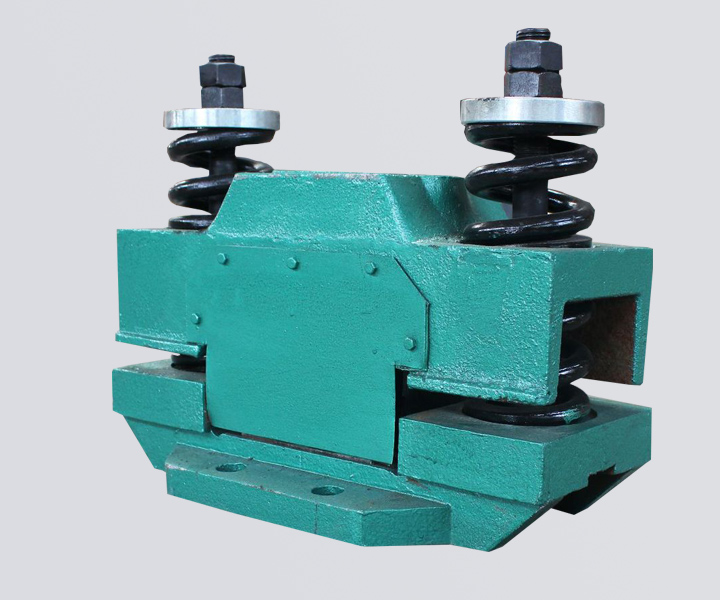

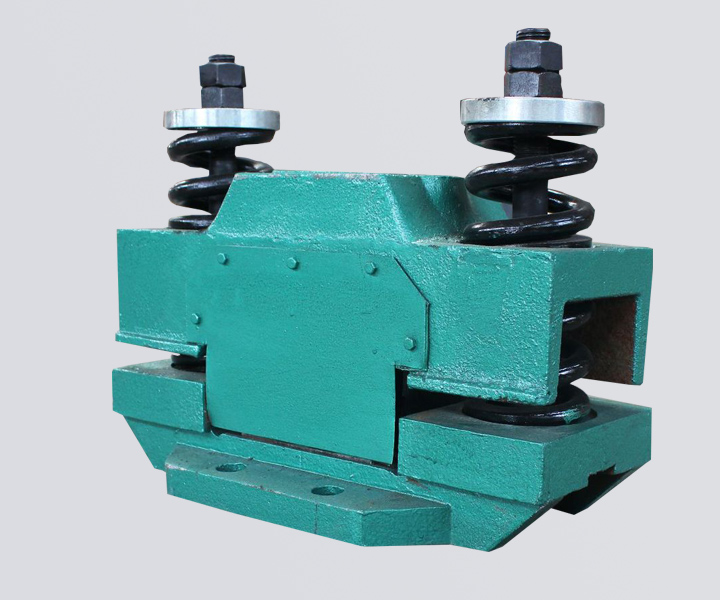

Motor-type warehouse wall vibrator: The anti-blocking device that uses the vibration motor as the excitation source, which also participates in the vibration, uses the 380V voltage as the working power supply, and can be designed as an explosion-proof type according to the actual situation of the user.

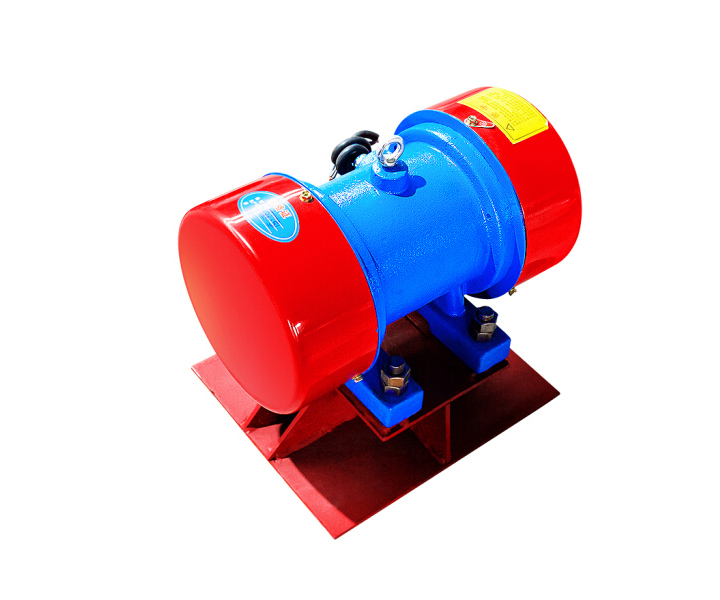

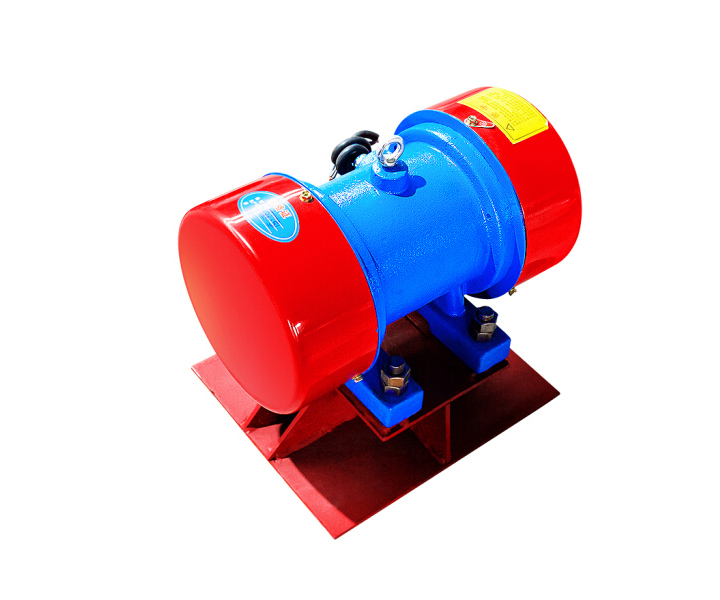

Electromagnetic type warehouse wall vibrator: The electromagnetic vibrator is installed on the outside of the constriction at the lower part of the powder silo. It relies on high-frequency vibration and impact force to ensure stable feeding. It uses 220V voltage as the working power supply. Automatic control can be realized.

When the warehouse wall vibrator is working, the high-speed rotation of the vibrating motor will generate periodic high-frequency vibration to the silo wall, and the periodic vibration of the anti-blocking device will make the material in the silo separate from the silo wall, on the one hand, eliminate the material in the hopper. The friction with the warehouse wall, on the other hand, the material is in an unstable state under the influence of the alternating speed and acceleration, which effectively eliminates the phenomenon of bridging and blockage caused by internal friction and component segregation, so that the material can be discharged from the warehouse mouth smoothly. Stable supply of required equipment.

1. The excitation force and power are properly matched, the vibration force is large, the body is light in weight, small in size and low in noise.

2. Because the hopper (silo, tank) warehouse wall vibrator is a strong resistance type vibration instead of resonance, it has a stable amplitude.

3. Multiple sets can be combined to achieve self-synchronization and can complete different process requirements.

4. The direction of the exciting force can be changed according to the installation method of the warehouse wall rapper.

5. The exciting force and amplitude can be adjusted steplessly just by adjusting the included angle of the eccentric block.

6. Complete specifications, can meet the work needs of various hoppers (silo/tank).

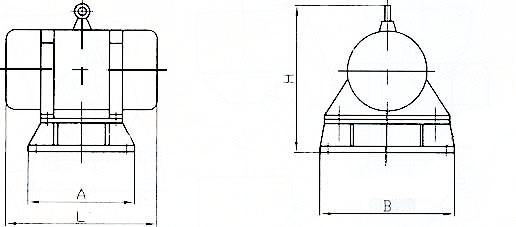

Electromagnetic type warehouse wall vibrator

Motor-type warehouse wall vibrator

| Model | Application | Matching vibration motor | Total weight (kg) | |||

| Warehouse wall thickness (mm) | Cone volume (t) | Model | Vibration force (KN) | Power (KW) | ||

| LZF-3 | 1.6-3.2 | 0.35 | YZD-1-2 | 1 | 0.12 | 18.5 |

| LZF-4 | 3.2-4.5 | 1 | YZD-2-2 | 2 | 0.22 | 25 |

| LZF-5 | 4.5-6 | 3 | YZD-3-2 | 3 | 0.25 | 35 |

| LZF-6 | 6-8 | 10 | YZD-5-2 | 5 | 0.37 | 65 |

| LZF-10 | 8-10 | 20 | YZD-10-2 | 10 | 0.75 | 120 |

| LZF-12 | 10-12 | 35 | YZD-15-2 | 15 | 1.5 | 150 |

| LZF-15 | 10-15 | 50 | YZD-20-2 | 20 | 1.5 | 166 |

| LZF-30 | 15-25 | 80 | YZD-30-2 | 30 | 2.5 | 207 |

| LZF-50 | 20-40 | 150 | YZD-50-2 | 50 | 3.7 | 310 |

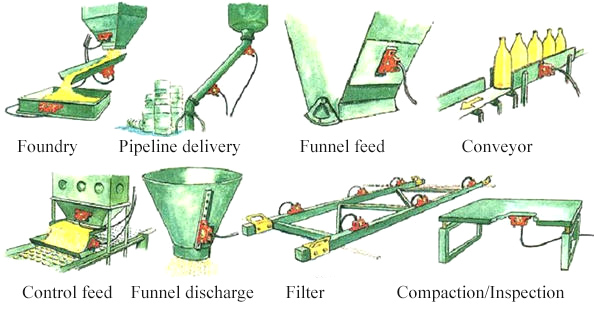

The warehouse wall vibrator is a special equipment to prevent and eliminate the arching of materials in the silo, tank or hopper, tubular passage, sticking silo and other occlusion phenomena, so as to ensure the smooth flow of materials and improve the automation degree of material transportation. It can be widely used in electric power, building materials, coal, mining, chemical industry, metallurgy, foundry, light industry, food, pharmaceutical, food, transportation and other industries. It can also be used as a vibration source for vibrating feeders, vibrating conveyors, vibrating funnels, vibrating chutes, etc. Ensure safe production, improve conveying efficiency and reduce labor intensity.

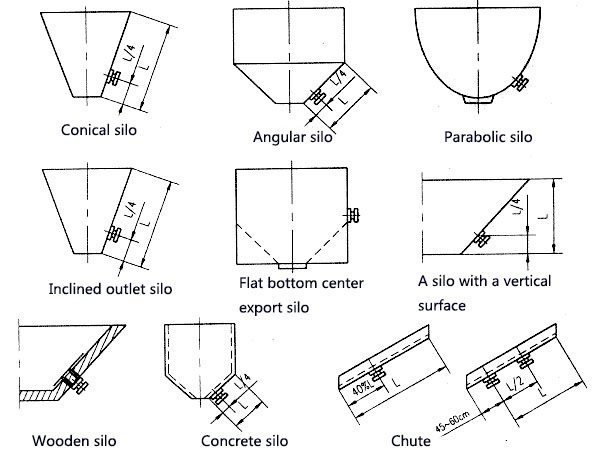

Conical silo: When the diameter of the installation site is greater than 1 meter, two warehouse wall vibrators should be installed.

All steel silo: warehouse wall vibrator The vibrator should be welded on the outer wall of the silo.

All-steel symmetrical pyramid-shaped silo: It should be installed on one side of the lower part of the silo along the center line of 1/4 or less than 1/4 of the height of the silo. If the other three sides or corners are required to also vibrate, it will be difficult to handle. The material should be installed at different heights on the opposite side.

The upper part is the concrete silo and the lower part is the steel hopper: the LZF type warehouse wall vibrator device should be welded on the outer wall of the steel hopper.

All-concrete granary and reinforced steel hopper: vibrating plate should be laid in the silo, and wall vibrator should be welded on the vibrating plate.

Silo for storing pure and coarse materials: no matter what the form of the silo is, a vibrating plate is installed in the silo, and the wall vibrator should be welded on the vibrating plate.

Chute: The vibrator of the warehouse wall should be welded on the part of the chute that is easy to stick and block.

Note: No matter what kind of installation method, as long as the device is installed on both sides of the silo, the difference between the horizontal height should be 50~100mm. The transmission range of the vibration force is generally 4~5m. The user can determine the number of units that should be installed in the entire silo according to the size of the silo.

Xinxiang Dahan Vibration Machinery Co., Ltd. has been established for 12 years, focusing on the production and sales of LZF warehouse wall vibrators, CZ electromagnetic warehouse wall vibrators and vibration motors, which are widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries. , Products with different vibration forces can be selected according to different silo shapes and material characteristics. There are many types of silo wall vibrators, and our company has passed ISO quality system certification and CE certification, and the product quality is guaranteed.

1. Select the power according to the wall thickness in the silo

For silo with wall thickness of 3.2-4.5mm, the recommended power is 0.12kw;

For a silo with a wall thickness of 4.5-6mm, the recommended power is 0.22kw;

For a silo with a wall thickness of 6-8mm, the recommended power is 0.37kw;

For a silo with a wall thickness of 8-10mm, the recommended power is 0.75kw;

For a silo with a wall thickness of 10-13mm, the recommended power is 1.1kw;

2. Select the number of units according to the volume of the silo

The quantity can be selected according to the volume of the silo. If it is a silo or silo of a power plant or a cement plant, it is necessary to keep the material out of contact with the silo wall and eliminate the friction between the material and the silo wall. At this time, the diameter of the silo is too large, and the flow rate is too large. If the pipe is blocked too long, the wall thickness is limited, and multiple units are required to be used together.

3. Select the type according to the on-site power supply

It is divided into electromagnetic type and motor type. Among them, the electromagnetic warehouse wall vibrator uses 220V voltage, and the motor type uses three asynchronous motors as the power source, and uses 380V voltage as the working power supply. Please choose according to the on-site use environment. corresponding model.

Precautions:

1. Regardless of whether the silo is separated or not, a silo with one outlet is a silo.

2. The selection of the vibrator for the silo wall is based on the thickness of the steel plate wall at the lower part of the silo and the volume of the silo. The wall thickness of the silo steel plate shall include the thickness of the inner lining plate.

3. Special conditions: The user can choose the equipment according to the condition of the actual material in the silo.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.