Electromagnetic warehouse wall vibrator is a necessary equipment to ensure stable material supply. It is used to prevent and eliminate the phenomenon of "blocking" and "tower arch" caused by internal friction, deliquescence, electrification and component segregation of materials in various warehouses; It can be used to remove all kinds of silo walls and pipeline adhesive materials, and can also be used as a vibration source for vibrating feeders, vibrating conveyors, vibrating funnels, and vibrating chutes. Widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries.

When the electromagnetic warehouse wall vibrator is working normally, the high-speed rotation of the vibrating motor will generate periodic high-frequency vibrations on the warehouse wall. Under the influence of alternating speed and acceleration, the material is in an unstable state, which effectively overcomes the internal friction and aggregation force of the material to eliminate the relative stability between the materials in the silo, so that the material can be smoothly discharged from the silo mouth.

1. The electromagnetic vibrator is used as the feeding device, which has a simple structure, smooth feeding and stable feeding system.

2. The anti-blocking ability can be adjusted to prevent and eliminate the occlusion of materials such as arching, tubular channels and sticking warehouses in the silo, tank or hopper, so as to ensure the smooth discharge of the flow material and improve the automation degree of material transportation.

3. It produces high frequency vibration and impact force, which can effectively avoid the blockage of materials.

4. Fully enclosed body, thickened aluminum alloy shell, integrated die-casting, strong and vibration-resistant, meet various harsh environments, up to IP65 protection level, prevent dust accumulation Meet various harsh environments and prevent dust accumulation.

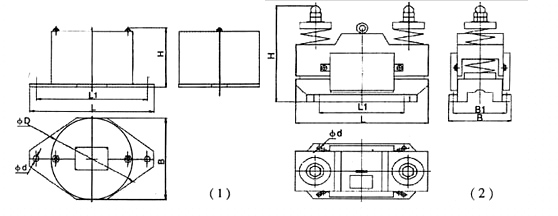

| Model |

Vibration force (kg) |

Power (KW) |

Voltage (V) |

Current (A) |

vibration frequency( time/min) |

vibration amplitude (mm) |

warehouse wall thickness (mm) |

| CZ10 | 10 | 0.008 | 220 | 0.11 | 3000 | 1.5 | 0.6-0.8 |

| CZ50 | 50 | 0.03 | 220 | 1.1 | 3000 | 1.5 | 1.2-1.6 |

| CZ100 | 100 | 0.06 | 220 | 1.0 | 3000 | 1.5 | 2.5-3.2 |

|

CZ250 (CZ200) |

250 | 0.1 | 220 | 1.6 | 3000 | 2 | 1.0-4.0 |

|

CZ600 (CZ400) |

600 | 0.15 | 220 | 2.3 | 3000 | 2 | 3.0-8.0 |

|

CZ1000 (CZ800 |

1000 | 0.2 | 220 | 3.8 | 3000 | 2 | 6.0-14 |

| CZ1500 | 1500 | 0.45 | 220 | 7.0 | 3000 | 2 | 6.0-14 |

Electromagnetic warehouse wall vibrator is used to remove all kinds of warehouse wall and pipeline bonding materials, and can also be used as a vibration source for vibrating feeders, vibrating conveyors, vibrating funnels, and vibrating chutes. Widely used in mining, metallurgy, chemical industry, building materials, machinery, food, chemical and other industries.

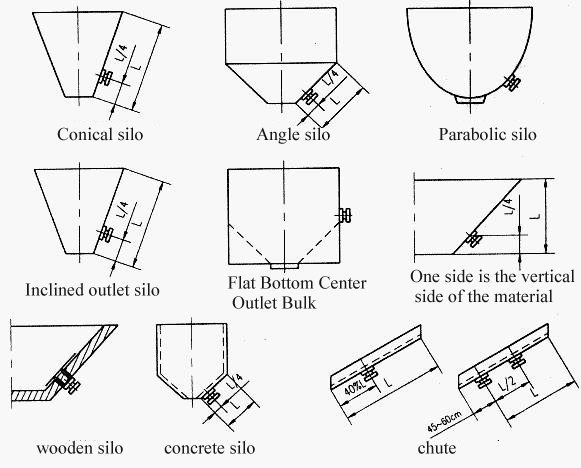

The installation position is generally located at or below 1/4 of the height of the silo cone. If more than two are installed, they can be installed at different heights on the symmetrical plane. For wood or concrete silo, vibrating plate can be installed on the silo wall to transmit vibration force and disperse activated materials, etc.

1. All-steel silo: The vibration motor device of the electromagnetic silo wall vibrator should be welded to the wall of the silo.

2. The upper part is the concrete silo, and the lower part is the steel hopper: the electromagnetic vibrator vibration motor device should be welded to the wall of the steel hopper.

3. All-concrete silo and steel hopper: Vibration plate should be placed in the silo, and the vibrator device should be welded to the vibration plate.

4. The silo for storing pure and coarse materials: regardless of the form of the silo, a vibrating plate should be placed in the silo. The vibrating motor device of the bin wall vibrator shall be welded on the vibrating plate.

5. Chute: The silo should be welded to the easily sticky and blocked parts of the chute.

6. Conical silo: When the diameter of the installation part is greater than 1 meter, please install two vibrators.

7. No matter which installation method is adopted, it only needs to be installed on both sides of the silo, and the level difference should be ensured to be 50-100 meters.

Since the establishment of Xinxiang Dahan Co., Ltd., we have adapted to the needs of customers with high quality products, high professional technology and high service quality, and have been extremely recognized by customers. Xinxiang Dahan electromagnetic warehouse wall vibrator manufacturers mainly operate: motor warehouse wall vibrator, electromagnetic warehouse wall vibrator, explosion-proof warehouse wall vibrator, vibration motor and other equipment, which are widely used in mining, metallurgy, chemical industry, building materials, machinery and other industries. , Products with different vibration forces can be selected according to different silo shapes and material characteristics. There are many types of silo wall vibrators, and our company has passed ISO quality system certification and EU CE certification, and the product quality is guaranteed.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.