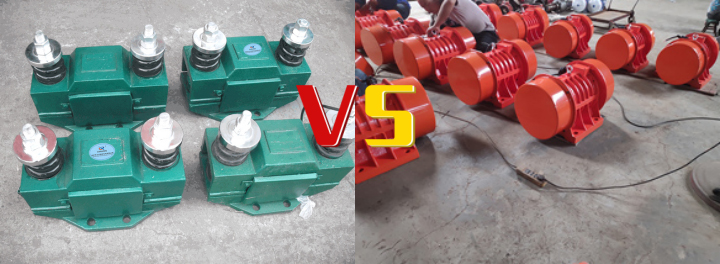

Electromagnetic vibrators and silo wall vibrators are both common vibration equipment, and they have their own advantages in different application scenarios. The following is a comparison of their advantages:

Advantages of electromagnetic vibrators:

Strong adjustability: The intensity and frequency of the vibration force can be flexibly controlled by adjusting the magnitude and frequency of the current.

High stability: The vibration force of the electromagnetic vibrator is stable and runs smoothly, which is suitable for occasions that require stable vibration.

Wide application: Suitable for vibrating equipment such as feeders and vibrating conveyors.

Advantages of silo wall vibrators:

Improve fluidity: Through the effect of high-frequency vibration, the fluidity of materials can be effectively improved, and blockage and dust generation can be reduced.

Simple maintenance: The silo wall vibrator has a simple structure and is easy to maintain, and does not require professional maintenance personnel for maintenance.

Wide range of application: It is suitable for silos of various shapes and materials, and can effectively solve problems such as material agglomeration and blockage in the silo.

Recommendations for purchasing electromagnetic vibrators and silo wall vibrators

When purchasing electromagnetic vibrators and silo wall vibrators, specific application requirements and scenarios need to be considered. The following is a comprehensive consideration for purchasing recommendations:

The principle of the electromagnetic vibrator is half-wave rectification. The electromagnetic coil is powered by alternating current through diode rectification. When the line is connected, the positive half-cycle pulsating DC voltage is applied to the electromagnetic coil. Due to the action of the electromagnet, a pulsed electromagnetic force is generated between the vibrating body and the machine base, and the vibrating body is attracted. At this time, the elastic system stores potential energy. The semi-two-stage tube is not conducting, and the electromagnetic force disappears. With the help of the potential energy stored in the elastic system, the vibrating body vibrates in the opposite direction. Repeatedly like this, the vibrating body vibrates back and forth at the frequency of alternating current.

The periodic high-frequency vibration of the vibrating body is transmitted to the silo wall through the "impact block". Periodic vibration of the warehouse wall. On the one hand, the material is out of contact with the warehouse wall, and on the other hand, the material is affected by the alternating speed and acceleration. It is in an unstable state, thus effectively overcoming the internal friction and aggregation of materials. Make the material discharge smoothly from the silo mouth.

The main components of the ordinary warehouse wall vibration motor are two parts: the vibration motor and the base. The vibration motor and the base are tightly fixed as a whole, but because the base is firmly installed on the wall of the silo, a single-mass directional forced vibration system is formed.

When the silo wall vibrator is working, the vibrating motor rotates at a high speed, which produces periodic high-frequency vibrations on the silo wall. Due to the periodic vibration of the anti-blocking device, on the one hand, the material is out of contact with the silo wall, and the material and the silo wall are eliminated. The friction of the silo wall, on the other hand, makes the material in an unstable state under the influence of alternating speed and acceleration, so as to effectively overcome the internal friction and aggregation force of the material, so as to eliminate the relative stability between the materials in the silo, so that The material is smoothly discharged from the silo port.

Electromagnetic vibrator selection: Suitable for people who need stable vibration force and flexible adjustability.

Silo wall vibrator selection: If your material has problems with agglomeration and clogging, you can choose a silo wall vibrator, which is easy to maintain and widely used.

Performance considerations:

Vibration force: Electromagnetic vibrators have stable vibration force, while silo wall vibrators can effectively reduce material agglomeration. Choose according to specific needs.

Adjustability: If you need to flexibly adjust the vibration force and frequency, electromagnetic vibrators are more suitable.

Cost-benefit evaluation:

Maintenance cost: Silo wall vibrators are generally easy to maintain and have low costs, while electromagnetic vibrators may require more complex maintenance.

Energy consumption: Consider the energy consumption of the equipment and choose a vibrator that meets energy efficiency standards.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.