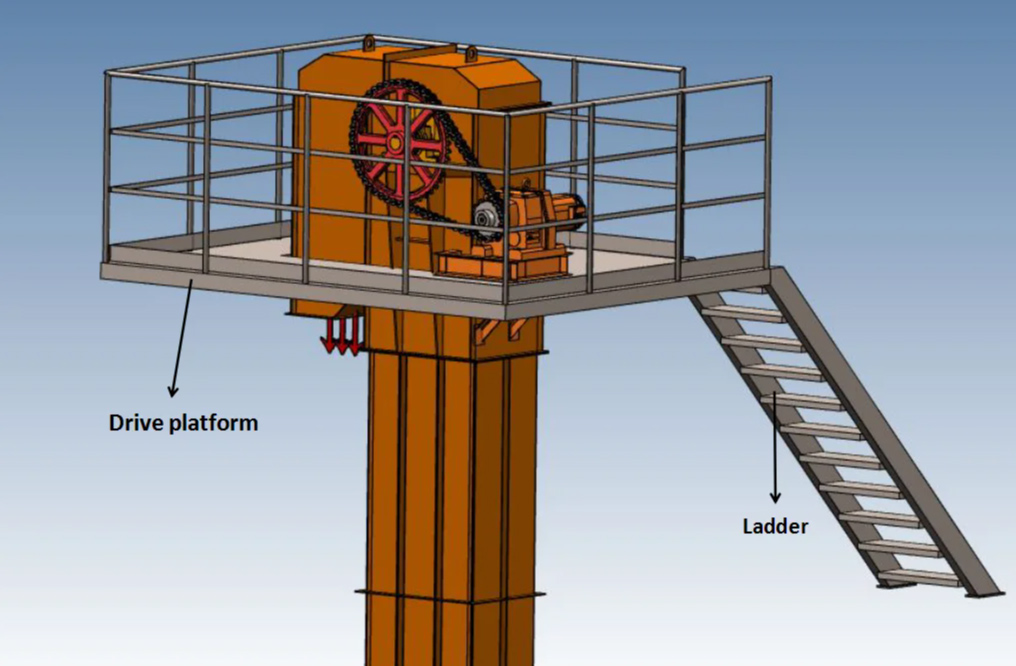

Cement bucket elevator is a commonly used material conveying equipment in the cement production process. It is used to lift materials such as raw materials, semi-finished products and finished products from low to high places, including the lifting of raw materials, furnace charges, pulverized coal and finished products. It has large conveying capacity and conveying distance, simple structure and stable operation.

Raw material transportation: Various raw materials are used in the cement production process, such as limestone, clay, iron ore, etc. These raw materials are usually stored on the ground or in open-air stockpiles, and need to be lifted by bucket elevators to furnace storage or crushers and other equipment for subsequent processing and crushing processes.

Clinker transportation: After grinding, mixing and other processes, cement clinker needs to be transported to rotary kiln and other equipment for calcination. Bucket elevator can efficiently transport clinker vertically to the required position to ensure continuous production of the production line.

Furnace charge transportation: Furnace charges in cement production are mixed from a variety of raw materials and need to go through processes such as grinding and firing. In the charge preparation process, the bucket elevator is used to lift the charge mixed with different proportions of raw materials to the charge warehouse or the hopper in front of the furnace to supply the kiln system.

Pulverized coal transportation: Pulverized coal is often used as fuel in cement production for the heat supply of kilns. The bucket elevator can lift the pulverized coal from the pulverized coal warehouse to the pulverized coal bunker or pulverized coal injection system to meet the combustion needs of the kiln.

Finished product transportation: The finished products on the cement production line include cement clinker and cement powder. Bucket elevators are used to lift clinker from the kiln system to the clinker warehouse, or lift cement powder from the mill to the cement silo for subsequent packaging and transportation processes.

The advantage of bucket elevators in cement plants is that they can handle large amounts of materials and have large conveying capacities and conveying distances. In addition, the bucket elevator has a simple structure and smooth operation, making it suitable for the production environment of cement plants.

There are also some caveats to the cement bucket elevator. Due to the complex nature of materials in cement production, some materials may be sticky and easy to agglomerate, which may cause blockage and jamming of the bucket elevator. In order to ensure the normal operation of the bucket elevator, corresponding anti-clogging measures need to be taken, such as regularly cleaning the bucket and installing anti-clogging devices.

Cement bucket elevator plays an important role in cement production and is used for transporting raw materials, charge, pulverized coal and finished products. Its efficiency and reliability enable the cement production line to run smoothly and meet the needs of the cement market.

If you want to learn more about cement hoists, we recommend that you click on the product link at the bottom of the page to get more detailed information.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.