Vibratory Sifter for Screening Flour employs a multi-layer sieve configuration, continuously separating feed into 2 to 6 different particle size ranges according to preset particle size specifications. During the screening process, it removes contaminants and other unwanted particles from wheat flour. The sieve mesh sizes cover a wide range from 20 to 500 mesh, allowing users to flexibly select the configuration based on the target product particle size—higher mesh numbers correspond to smaller sieve apertures, effectively removing minute impurities such as foreign objects, agglomerates, and oversized particles, resulting in a very fine and uniform product. It can also grade flour by particle size as needed.

Flour screening for food processing companies:

1. Large bakery, boutique pastry processing enterprise

2. Integrated processing enterprises such as dried noodles, steamed buns, steamed buns, dumplings, etc.

3. Ready-mixed powder

4. Other food processing companies

There are three targeted solutions designed for different enterprise scales and processing volumes

Plan A:

Capacity: 500-2000 kg/h

Mesh number: 20 mesh (aperture: 0.85mm)

Configuration scheme: 450/550 type filter sieve DH-800 type vibratory sifter

Equipment application description: bagged flour unpacked manually added flour vibratory sifterfilter sieve turnover bucket dough mixer mixer

Plan B:

Capacity: 2000-3000 kg/h

Mesh number: 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm)

Configuration scheme: 800 type dust-free screening and feeding station, ZPS-800 type direct discharge sifter

Equipment application description: bagged flour unpacking manual feeding dust-free screening and feeding station direct discharge sifter vacuum conveying kneading machine mixer

Plan C:

Capacity: 2000-10000 kg/h

Mesh number: 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm) OR40 mesh (aperture: 0.425mm)

Configuration scheme: automatic multi-point feeding system

Equipment application description: Bulk truck 40 tons buffer warehouse centrifugal screen dust-free screening and feeding station dust removal weighing system dough mixer mixer

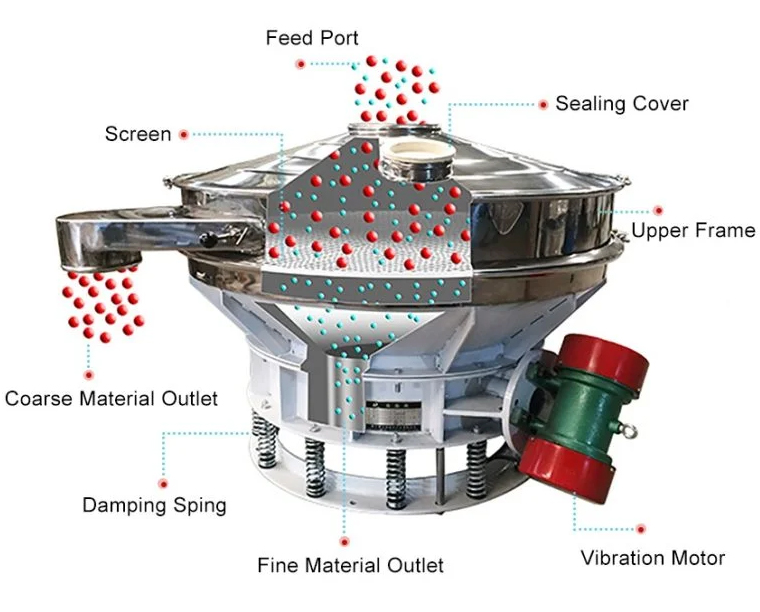

The working principle of the vibrating sifter for screening flour is to vibrate the screen frame through the excitation force generated by the vibration motor, thereby screening the raw material particles on the screen.

The specific process is: after the raw materials are evenly distributed in the screen frame, they are affected by the vibration force. The large particles move to the front edge under the action of the vibration force and are gradually discharged from the equipment outlet, while the small particles pass through the screen and are discharged from below.

The material outlet is discharged, thus realizing the separation of materials with different particle sizes.

| Model | DH600 | DH800 | DH1000 | DH1200 | DH1500 |

| Single motor power | 0.18 | 0.18 | 0.25 | 0.55 | 0.55 |

| Dual motor power | 0.12*2 | 0.18*2 | 0.18*2 | 0.25*2 | 0.55*2 |

| Screen diameter | 550mm | 750mm | 970mm | 1170mm | 1470mm |

| Materials | Proportion | Mesh | Model | Processing Method | Capacity(kg/hr t/hr) |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Rice Flour | 0.5 | 100 | DH-1000-1S | Dry | 300kg |

| Corn Starch | 0.6 | 40 | DH-1000-1S | Dry | 1600kg |

| Degreased toner | 0.57-0.7 | 24 | DH-1000-1S | Dry | 3000kg |

| Milk powder | 0.51-0.8 | 12 | DH-1200-1S | Dry | 1600kg |

Specializing in the production of vibrating screen equipment, no middlemen, lower prices, more than 30 product patents, CE, ISO certification, etc.

Professional R&D team, customized design, advanced equipment and technology, good product quality control.

Products are exported to more than 70 countries overseas, perfect pre-sales and after-sales service, free technical guidance, one-year warranty.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.