The sieve is as fine as 500 mesh or 0.028mm, and the flour is more uniform.

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

It is mainly used to remove silk threads, stones, bran, insect eggs, agglomerates, etc. contained in flour

Commonly used are 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh, 60 mesh

Household flour: 40 mesh – 60 mesh

For simple flour removal, use 14-24 mesh

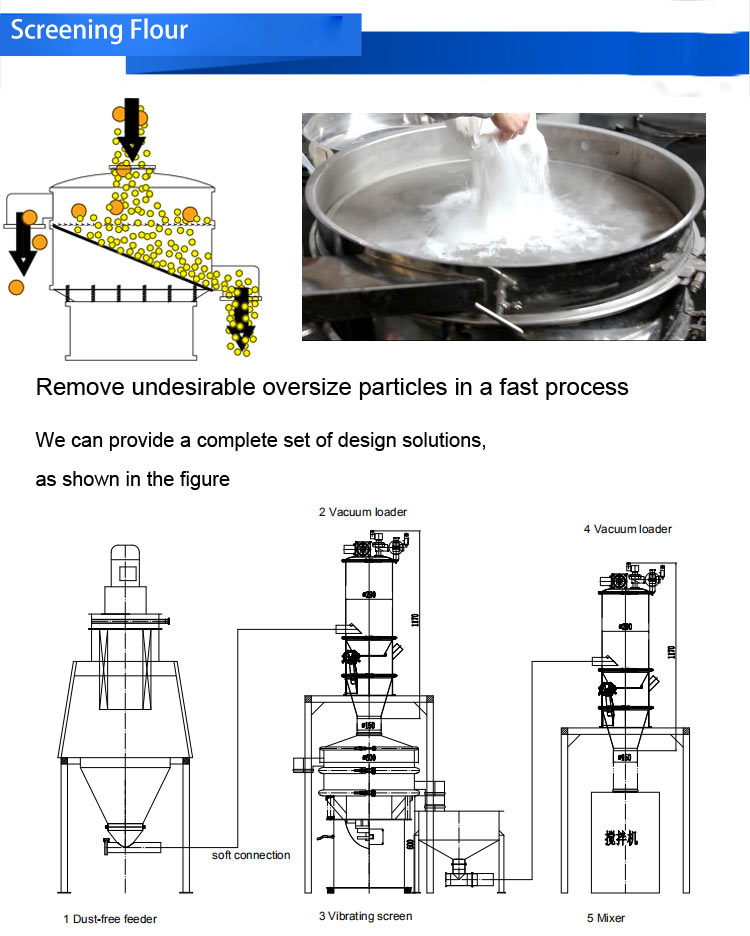

Flour shaker sifter is used in food factories and flour production lines for safety screening and inspection screening of fine flour. It can remove agglomerates, foreign matter and pollutants in flour, improve product quality before packaging, and can sieve a large amount of flour of any type, including Hard and soft wheat, semolina, cornmeal, etc.

Flour shaker sifter is mainly used in flour production lines, food processing factories, bakeries, boutique pastry processing enterprises, dried noodles, steamed buns, steamed buns, dumplings and other comprehensive processing enterprises. The main purpose is to prevent foreign matter from entering the next process and causing food safety problems.

The effect of sifting flour:

| State of Flour | Mesh Size | Capacity (kg/hour) |

| Dry | 20 mesh (0.8mm) | 2000 |

| 30 mesh (0.55mm), 45 mesh (0.18mm) | 1500 | |

| 80 mesh (0.18mm) | 1200 |

1. Improve the flour: make the flour more fluffy (especially needed for puffed food), the flour is evenly extracted, and the gluten is evenly distributed.

2. Removing impurities: When the flour reaches a certain fineness, it can effectively remove the thread ends, drum skins, insect eggs, stones, metal impurities, etc. contained in the flour, effectively purify the flour, and improve the working efficiency of the food factory.

Pour the flour into the vibrating sieve driven by the motor, the material (fine material) close to the sieve hole will fall under the sieve through the sieve, and the material (coarse material) larger than the size of the sieve hole will stay on the sieve surface and flow out from the outlet. Discharging, impurities and oversized contaminants are removed before the flour passes through a screen and enters the rest of the production line.

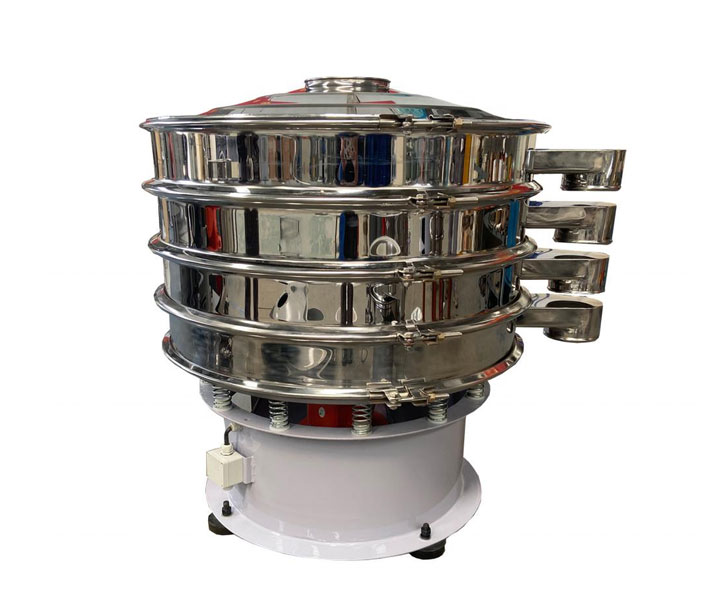

1. The screen is made of SUS304 or 316L stainless steel, mirror polished, and the internal and external surface finish is 0.1-0.2RA, designed to meet the strict engineering and safety standards required by the food industry.

2. The product is poured into the vibrating sieve, before the flour passes through the sieve to the rest of the production line, the impurities and oversized pollutants are removed to ensure the safety, sanitation and quality of the product.

3. According to the different process requirements of the industry, the output is 100-3200 kg/hour, and the screening is about 30 mesh (the fineness can reach 500 mesh).

4. The fully enclosed structure prevents dust from flying and eliminates the problem of dust in the air. Manual interaction is pollution-free.

5. It is quickly disassembled and easy to clean, thereby increasing productivity and avoiding any chance of cross-contamination between batches.

6. The compact size and footprint meet industrial and commercial needs, and can be flexibly installed into any production line.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 |

| DH-600 | 600 | 0.25 | |||

| DH-800 | 800 | 0.55 | |||

| DH-1000 | 1000 | 0.75 | |||

| DH-1200 | 1200 | 1.1 | |||

| DH-1500 | 1500 | 1.5 | |||

| DH-1800 | 1800 | 2.2 |

| MAYERIALS | WAY OF WORKING | MESH OPENING | CAPACITY (kg/h) |

MODEL |

| Milk powder | dry | 16.2 mesh | 2000 | DH-1200-1S |

| Starch | dry | 80 mesh | 1200 | DH-2000-2S |

| Wheat starch | wet | 200 mesh | 3200 | DH-2000-1S |

| Flour | dry | 24 mesh | 1500 | DH-1000-1S |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.