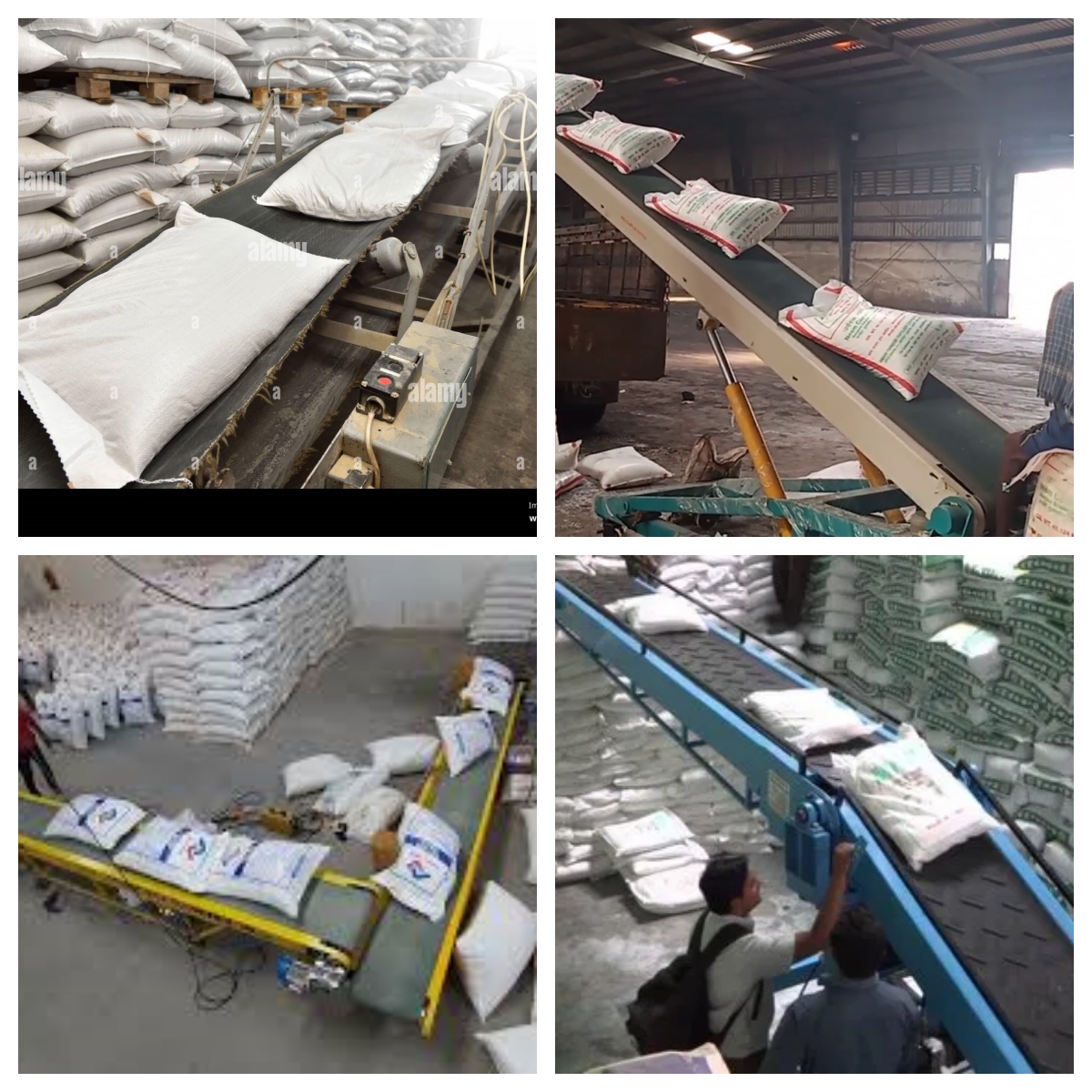

Conveyor systems specifically designed for handling flour and other powdery or granular materials in the food processing industry

![]()

![]()

Price:$980.00 - $7,800.00/Set

Consult now and enjoy a 10% discount

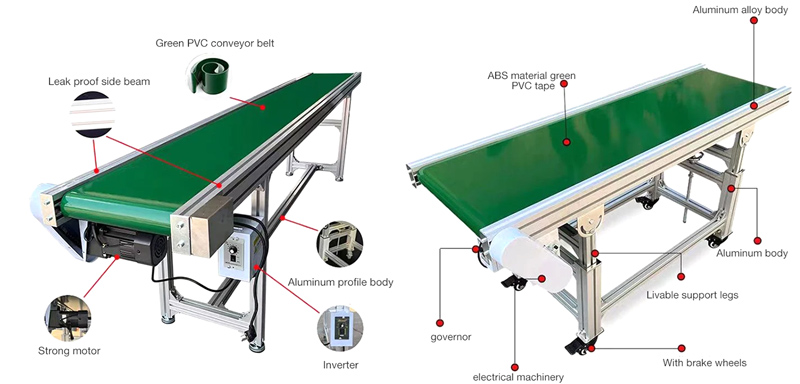

Belt material: food grade PVC

Belt width: 300-1500mm

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Conveying angle: 0-90°

Frame material: SUS304 stainless steel

Weight: 300 kg

Application: It is commonly used in flour mills, bakeries, and other food production facilities.

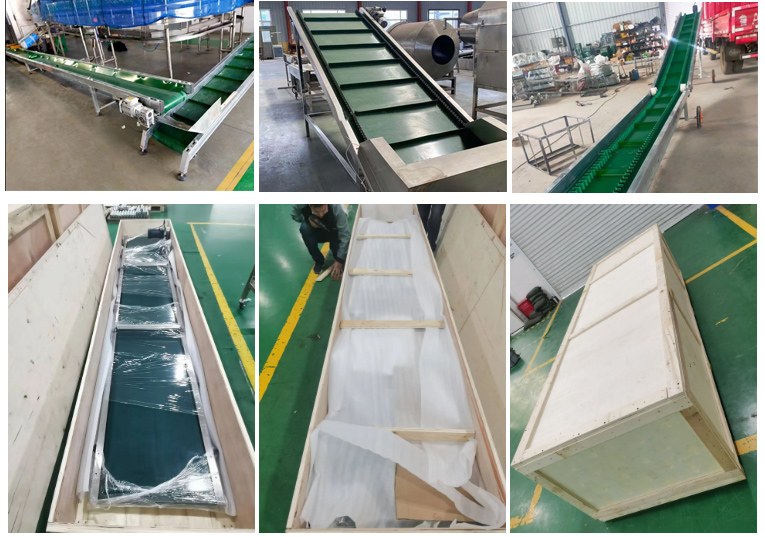

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Belt conveyor for flour is a type of conveyor system used specifically for handling flour and other powdered or granular materials in the food processing industry. It is designed to transport flour smoothly and efficiently from one processing stage to another, such as from storage silos to mixing equipment or from processing equipment to packaging machines.

Belt conveyors for flour are designed to meet the hygienic requirements of the food industry. They are easy to clean, resistant to contamination, and comply with food safety regulations. These conveyors provide a continuous and efficient method of transporting flour, reducing manual handling and improving operational efficiency in flour mills, bakeries, and other food production facilities.

Belt conveyors for flour have a wide range of application scenarios in the flour processing industry. Its main applications include:

1. Flour transportation: Belt conveyors are used to transport flour from one processing stage to another. They can move flour from storage silos to mixing or packaging areas, ensuring a continuous and efficient production process.

2. Packaging: Belt conveyors are often used in flour packaging production lines. They transport flour from processing equipment to packaging machines, ensuring a smooth and controlled process for accurate filling and packaging.

3. Storage and distribution: Belt conveyors are used to store and distribute flour in warehouses or distribution centers. They can transport flour from bulk storage silos to smaller bins or packaging areas for further distribution.

Belt conveyor for flour realizes the transportation of flour through the cyclic movement of the belt between the rollers. Here's how it works:

Belt drive system: The belt is composed of a transmission roller and a force-bearing roller. The transmission roller is driven by a driving device, causing the belt to produce continuous cyclic motion.

Flour loading: Flour enters the belt from the loading point and is gradually transported to the unloading point as the belt moves.

Support structure: The belt is supported by a support structure to ensure that the belt remains stable during operation.

Speed regulating device: By adjusting the speed of the driving device, the conveying speed and amount of flour can be controlled to meet production needs.

Cleaning device: In order to avoid flour contamination and equipment clogging, a cleaning device is usually equipped to clean the belts and conveyor channels regularly.

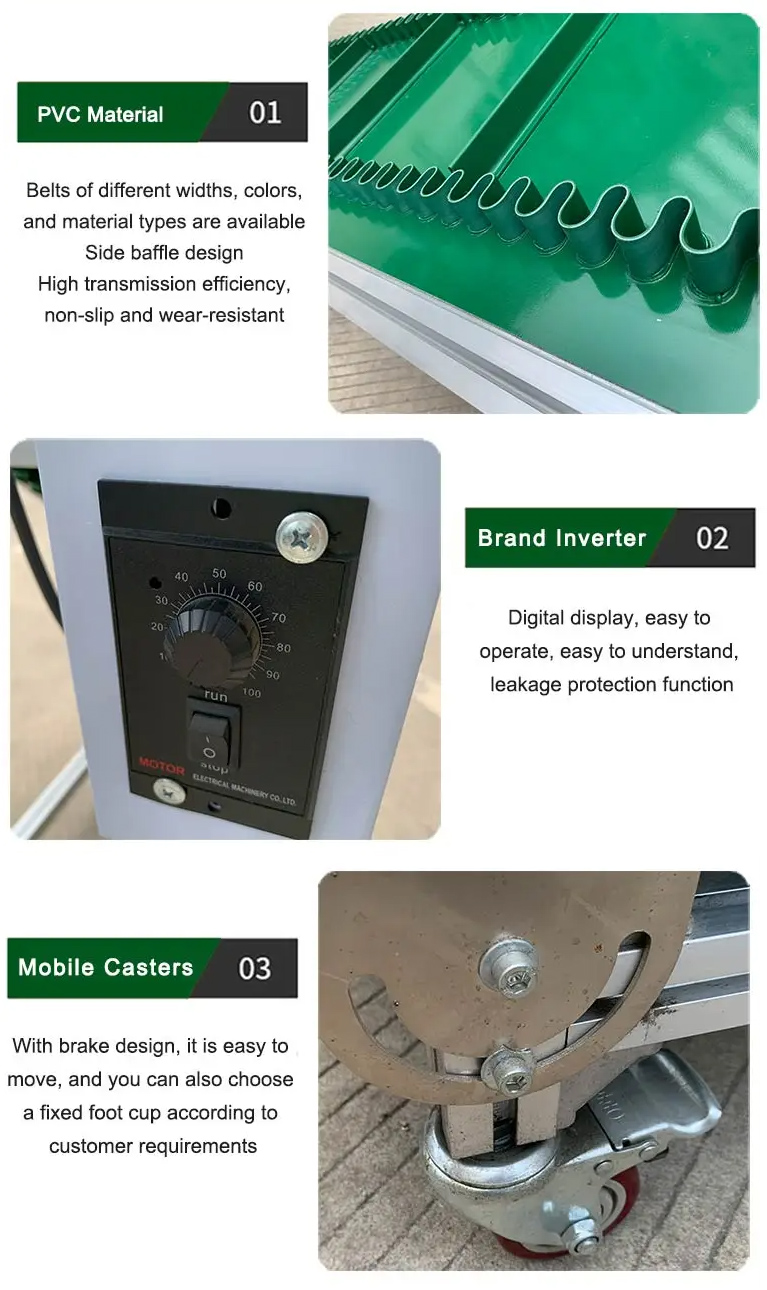

Hygienic Design

Belt conveyors for flour are designed with food safety and hygiene in mind. They are easy to clean, resistant to contamination, and comply with food industry regulations.

Efficient Material Handling

Belt conveyors provide a continuous and reliable method of transporting flour, reducing manual handling and improving operational efficiency.

Flexibility

Belt conveyors can be customized to fit the layout and space constraints of the facility. They can be inclined, declined, or curved to adapt to the specific production requirements.

Gentle Handling

Belt conveyors for flour are designed to handle the delicate nature of flour without damaging or causing excessive breakage of the particles.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

Maintaining sanitation and preventing contamination in flour mills can be challenging due to the nature of the environment and the potential sources of contamination. Some common challenges include:

1、Cross-Contamination: Cross-contamination is a significant concern in flour mills. It can occur when different types of flour or other ingredients come into contact with each other, leading to the mixing of allergens or contaminants. Proper segregation and cleaning procedures are necessary to prevent cross-contamination and ensure the purity of the flour.

2、Pest Control: Flour mills are susceptible to pest infestations, such as rodents, insects, and birds, which can introduce contaminants and compromise the quality of the flour. Effective pest control measures, including regular inspections, proper storage practices, and pest exclusion methods, are essential for preventing contamination.

3、Equipment Cleanliness: Flour milling equipment, including conveyors, grinding mills, and sifting machines, can accumulate flour dust and other residues over time. These residues can harbor bacteria, mold, or allergens, leading to contamination of the flour. Regular cleaning and sanitation

Belt Material: The conveyor belt is typically made of food-grade materials, such as PVC or polyurethane, which are hygienic and comply with food safety regulations.

Belt Design: The belt is usually smooth or lightly textured to prevent flour particles from sticking to the surface and ensure smooth material flow.

Belt Width and Length: Belt conveyors for flour are available in various widths and lengths to accommodate different production requirements and space limitations.

Adjustable Speed: The conveyor speed can be easily adjusted to control the flow rate and ensure precise material handling.

Xinxiang Dahang is a company specializing in conveying equipment manufacturing, headquartered in Xinxiang City, China. As a professional manufacturer, Xinxiang Dahan is committed to the design, production and sales of various types of conveying equipment, including flour belt conveyors. Xinxiang Dahan is able to customize conveying equipment according to customers' specific requirements, including customized sizes, functions and designs to meet the needs of different industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.