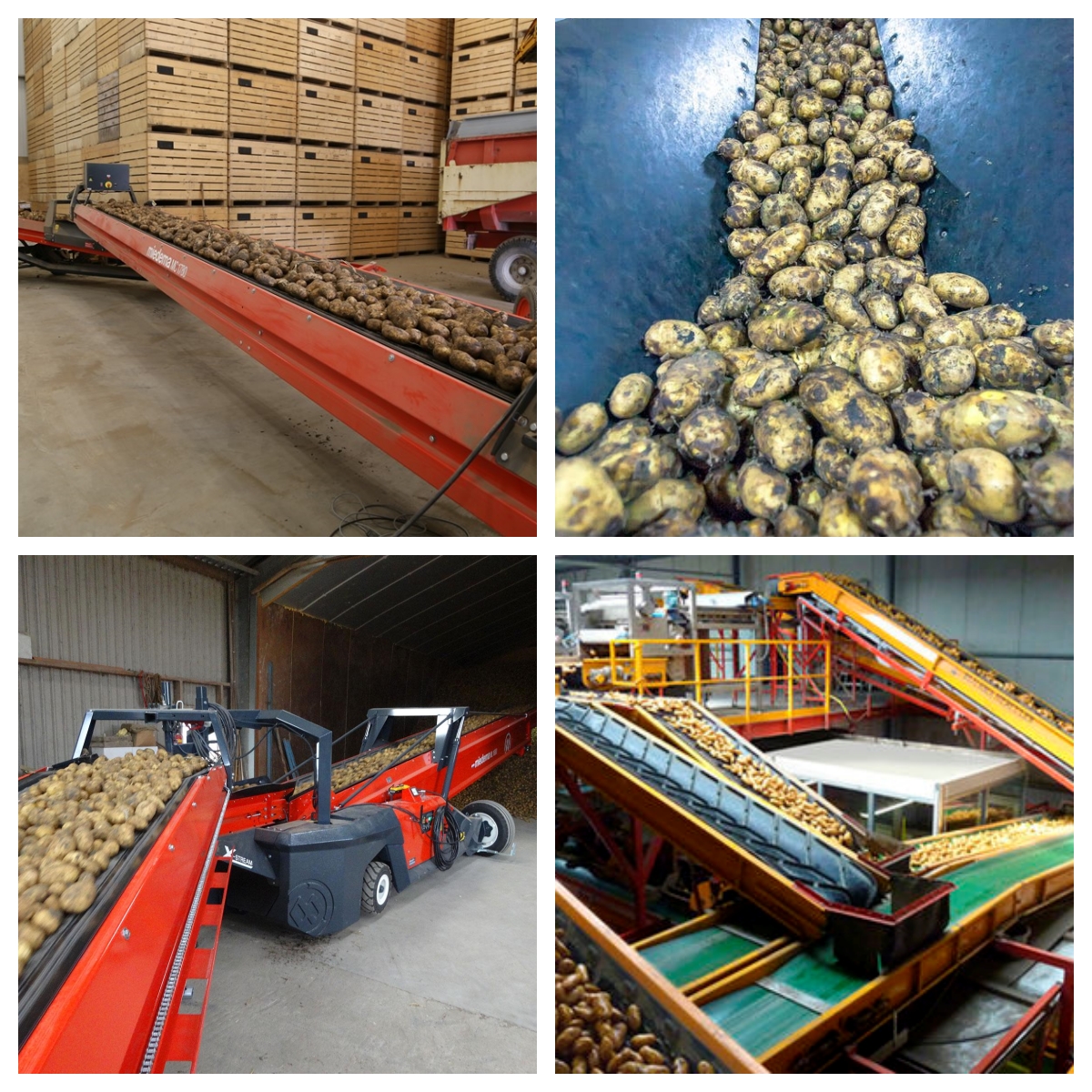

Helps potatoes move smoothly and efficiently through all stages of production.

![]()

![]()

Price:$300.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Belt Width: 400/500/650/600/800/1000/1200/1500mm

Conveying length: 10-30 meters

Conveying capacity: 30-3000t/h

Conveying speed: 1.25-2.0m/s

Voltage: 380V

Power: 0.4kW - 22kW

Application: Can be used in a variety of applications such as transferring potatoes between different processing stages, loading and unloading trucks or storage facilities and aligning potatoes for sorting or grading.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Potato belt conveyor is a specialized type of conveyor system designed specifically for handling potatoes during various stages of processing, such as harvesting, cleaning, sorting, grading, and packaging. It is commonly used in potato farms, processing plants, and packaging facilities.

The belt used in a potato belt conveyor should be selected based on the specific requirements of potato handling. It should be durable, food-grade, and resistant to abrasion, moisture, and chemicals. Common belt materials include PVC, polyurethane, or rubber, with a smooth or textured surface depending on the application.

Harvesting: In agricultural settings, potato belt conveyors are used to transport freshly harvested potatoes from the field to storage or processing facilities.

Processing: Within processing plants, these conveyors help move potatoes between different stages of processing, such as washing, peeling, cutting, and packaging.

Packaging: Potato belt conveyors play a critical role in transferring potatoes to packaging stations where they are prepared for distribution to retailers or consumers.

Storage: Conveyors are also used to transport potatoes to storage facilities, ensuring efficient and organized storage of the produce.

Potato belt conveyors are widely used in the following common occasions:

Potato processing factory: Potato processing factories usually use belt conveyors to handle different processes of potatoes, including cleaning, peeling, cutting, cooking and packaging. Conveyors can efficiently transport potatoes from one process to another, improving processing efficiency.

Agricultural product storage centers: In agricultural product storage centers, potato belt conveyors are used to transport potatoes from harvesting or sorting areas to storage facilities or warehouses. This helps improve potato storage efficiency and management.

Food processing plants: In addition to specialized potato processing plants, some food processing plants also use potato belt conveyors to process potato-related products, such as potato chips, mashed potatoes, and potato products.

Farmland harvesting: During the farmland harvesting process, potato belt conveyors are used to transport potatoes from the ground to the harvester or centralized processing area. This improves potato harvesting efficiency and work quality.

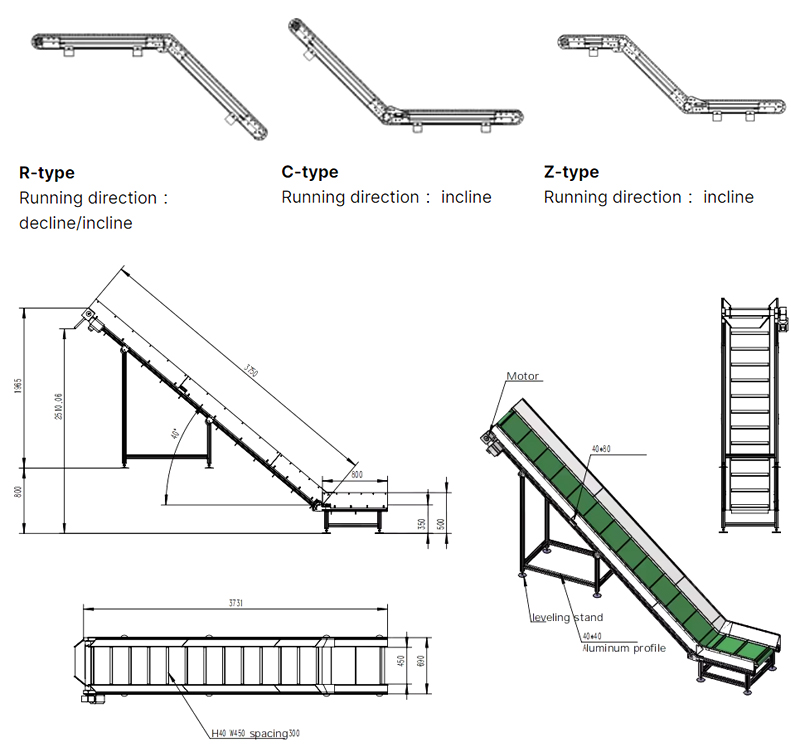

Here are the uses and applications of different types of potato belt conveyors:

| Type | Main uses | Applications | |

| Horizontal conveyor |  |

Transport potatoes from the harvesting field or washing machine to processing equipment (such as grading, cutting machine) or packaging machine. | Potato planting base, potato processing plant |

| Inclined conveyor |  |

Transport potatoes from a lower position to a higher position, such as to a storage warehouse or a higher level of the processing line. | Potato planting base, potato processing plant |

| Telescopic conveyor |  |

Flexibly adjust the conveying length according to production needs to adapt to production lines of different sizes. | Potato processing plant, logistics center |

| Conveyor with side guard |  |

Prevent potatoes from falling during transportation and improve transportation efficiency. | Potato processing plant, logistics center |

| Conveyor with cleaning device |  |

Prevent soil or other debris from adhering to the surface of potatoes and improve product quality. | Potato washing machine rear section |

| Conveyor with weighing device |  |

Weigh potatoes during transportation to facilitate production control. | Potato packaging workshop |

Efficiency

By automating the transportation process, potato belt conveyors improve overall efficiency and throughput in potato processing operations.

Reduced Labor

These conveyors help reduce the need for manual handling of potatoes, saving labor costs and minimizing the risk of injuries.

Product Quality

Gentle handling provided by the conveyor system helps maintain the quality and appearance of the potatoes, reducing waste and improving customer satisfaction.

Flexibility

Potato belt conveyors can be customized to meet specific processing requirements and can be integrated into existing production lines for seamless operation.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

In order to tune the potato belt conveyor to match specific processing stages, several parameters can be modified according to the requirements of each stage. Here are some ways to achieve the necessary adjustments:

Speed control: The speed of the potato belt conveyor can be adjusted to suit the processing stage. Slower speeds may be suitable for delicate tasks such as cleaning or inspection, while faster speeds can be used for transport between processing machines or packing stations. Conveyor speed can be adjusted as needed using a variable frequency drive (VFD) or motor controller.

Inclination/declination angle: The inclination or descent angle of the conveyor can be adjusted to meet the specific requirements of the processing stage. For example, during cleaning or washing, a slight slope can be used to allow water to drain efficiently from the potatoes. Conversely, a flatter or sloped angle may be suitable for sorting or packing stages. Adjustable legs or belt brackets make it easy to change the angle of the belt.

Height adjustment: The height of the potato belt conveyor can be customized to match the height of other processing equipment or the working level of the operator. This ensures a smooth and efficient transfer of potatoes between the different stages. Height-adjustable outriggers or a hydraulic system can be used to raise or lower the conveyor as needed.

Conveyor belt width: According to the quantity of processed potatoes or the requirements of a specific stage, the width of the conveyor belt can be adjusted. This accommodates larger or smaller quantities of potatoes and ensures optimum material flow through the processing line.

Integration of additional equipment: The potato belt conveyor can be modified and equipped with additional equipment to suit specific processing stages. For example, brushes, rollers or vibrating screens can be integrated into conveyors to aid in cleaning, sorting or grading operations. These additional components can be adjusted or replaced as required for the different processing stages.

| Convey products | Purpose of usage | Application occasions | Conveying length | Conveying capacity |

| Potato | Warehousing and storage | Agricultural products storage center | 20 meters | 1,000kg/h |

| Potato | Food processing | food processing plant | 15 meters | 800kg/h |

| Potato | Farm harvest | Farm harvesting operations | 5 meters | 300kg/h |

| Potato | Feed processing | Feed processing plant | 12 meters | 600kg/h |

Xinxiang Dahan Factory is a well-known manufacturer specializing in the production of potato belt conveyors. The factory has advanced production equipment and a technical team, and is committed to providing customers with high-quality potato conveying solutions. Xinxiang Dahan's potato belt conveyors are made of high-quality materials, have stable performance and reliable operation, and are widely used in potato planting, processing and other fields. The manufacturer focuses on product quality and customer service, and provides customers with customized solutions to meet different needs.

When choosing a potato belt conveyor, consider key factors for optimal performance:

1、Potato Characteristics: Ensure the conveyor matches potato size and shape.Pick a belt material that protects potato skin.Ensure the conveyor can handle potato weight.

2、Throughput: Conveyor capacity should match potato volume.Adjust conveyor speed for processing line needs.

3、Conveyor Size Length:: Fit distance between processing stations.Width: Handle desired potato flow rate.

4、Inclination: Avoid slippage or damage on inclines.

5、Belt Material: Choose a tough, abrasion-resistant material.Use food-safe materials meeting regulations.Opt for easy-to-clean, maintainable materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.