Designed for transporting rice within rice processing or manufacturing facilities.

![]()

![]()

Price:$680.00 - $5,800.00/Set

Consult now and enjoy a 10% discount

Belt width: 300-1500mm

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Conveying angle: 0-90°

Frame material: SUS304 stainless steel

Weight: 300 kg

Application: It is commonly used in rice mills, processing plants and storage facilities to efficiently transport large quantities of rice from one location to another.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

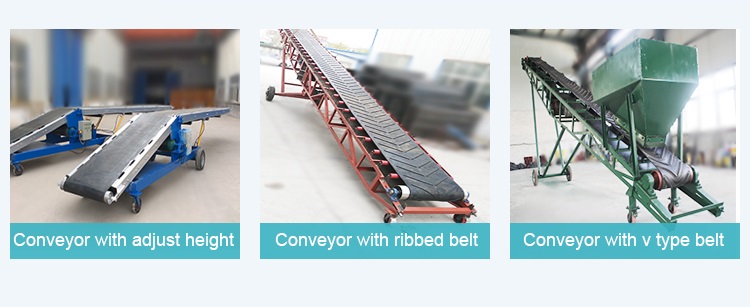

Rice belt conveyor is a type of conveyor system specifically designed for the transportation of rice. It is commonly used in rice mills, processing plants, and warehouses to move rice from one location to another within the facility.Rice belt conveyors can be customized to suit specific requirements, including length, width, and additional features such as inclined or curved sections. They are designed for easy maintenance and cleaning to ensure hygiene and prevent contamination.

The rice belt conveyor consists of a continuous belt made of durable material, such as rubber or PVC, that is supported by rollers or pulleys. The belt is driven by a motor, which moves it along the designated path. The conveyor's length and width can vary depending on the specific requirements of the facility.

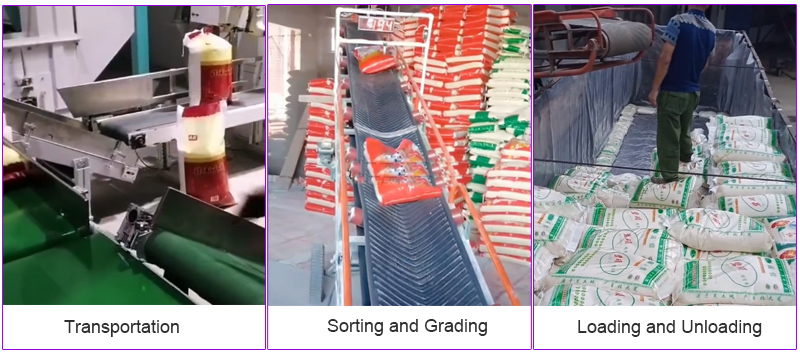

1.Transportation: The primary function of a rice belt conveyor is to transport rice from one location to another within the processing facility. This includes moving rice from the cleaning and drying stages to storage silos or packaging areas.

2.Sorting and Grading: In some cases, rice belt conveyors are used in conjunction with sorting and grading systems to separate rice grains based on size, quality, or other criteria as they move along the conveyor belt.

3.Loading and Unloading: Rice belt conveyors facilitate the loading and unloading of rice onto and off the conveyor belt, allowing for seamless transfer between different processing stages or storage areas.

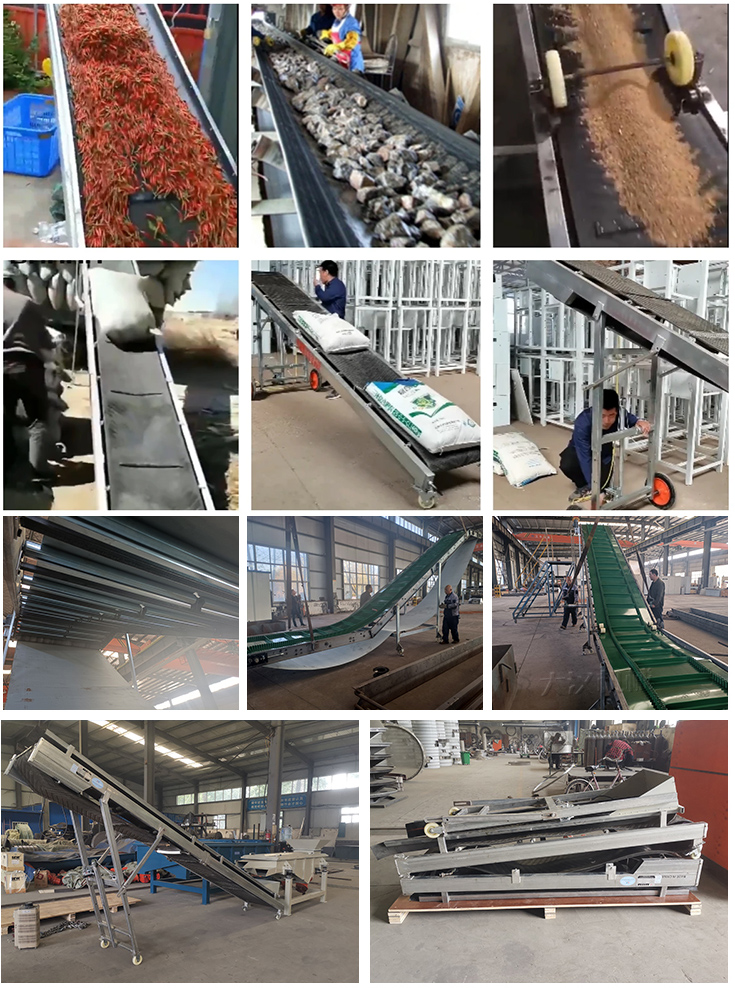

Some of the common applications of rice belt conveyors in the rice industry help to increase efficiency, reduce manual handling and maintain the quality of rice during processing and transportation. , common applications include:

1. Rice milling plant: used to transfer rice from the cleaning stage to the hulling or milling process. They also transport the rice from the milling process to the polishing, grading and packaging stages.

2. Rice processing plants: Rice belt conveyors are used in large rice processing plants to transport rice between different processing equipment and machinery. They help rice flow smoothly from washers, dryers, hullers, polishers, graders and sorters, ensuring efficient operation and minimizing manual handling.

3. Warehouse: Used in warehouses and storage facilities to transport rice from processing plants to storage bins or silos. They enable automatic transfer of rice, reducing the need for manual labor and ensuring that rice is stored in an organized and efficient manner.

Rice belt conveyors are commonly used to convey bulk and bagged rice in various applications. Here's how they apply in each scenario:

Conveying bulk rice:

Rice Milling Machines: Rice milling belt conveyors are used to transport large quantities of rice from storage bins or silos to the different processing stages within rice milling machines. They facilitate the transfer of rice from the cleaning process to the milling, polishing, grading and packaging stages.

Rice Storage Facilities: In a warehouse or storage facility, rice belt conveyors are used to transfer bulk rice from processing plants to storage bins or silos. They enable efficient, automated transportation of rice, reducing the need for manual labour, and ensuring proper storage of bulk rice in an organized manner.

Rice export: Rice belt conveyors are used in ports and docks to load bulk rice onto ships or containers for export. They facilitate the efficient transfer of large volumes of rice from storage facilities to ships, ensuring smooth logistics and timely exports.

Conveying bagged rice:

Packing Lines: Rice belt conveyors play a vital role in conveying bagged rice in packing lines. They transport the rice bags from the filling station to the labelling, sealing and palletizing station. The conveyor system ensures consistent and efficient movement of bagged rice, optimizing the packaging process.

Distribution Centers: In distribution centers and logistics facilities, rice belt conveyors are used to transport bagged rice from storage areas to loading docks. They facilitate the loading and unloading of bags onto trucks or containers for distribution to retailers or export.

Retail Stores: Rice Belt Conveyors can also be used in retail stores or supermarkets to move bags of rice from storage areas to display shelves. They streamlined the inventory process and ensured a continuous supply of rice to meet customer demand.

The design of the conveyor belt, including its width, texture, and cleats, can be customized to suit the specific characteristics of the rice grains being transported. The belt's textured or cleated surface helps prevent slippage and ensures that the rice grains remain securely on the conveyor during transportation.

Additionally, the speed and incline of the conveyor can be adjusted to optimize the movement of different types of rice grains. This flexibility allows rice belt conveyors to accommodate variations in flow rates and processing requirements, ensuring efficient handling of various rice grain sizes.

Efficiency

Rice belt conveyors provide an efficient means of transporting large quantities of rice. They enable continuous and automated operation, reducing the need for manual labor and increasing overall productivity. The conveyor system can move rice at a consistent speed, ensuring a steady flow of material and optimizing the production process.

Gentle Handling

Rice belt conveyors are designed to handle rice grains delicately. The smooth and flat surface of the conveyor belt minimizes friction and impact, reducing the chances of rice breakage or damage during transportation. This gentle handling helps to maintain the integrity and quality of the rice grains.

Flexibility

Rice belt conveyors can be customized to suit specific layout requirements and operational needs. They can be designed to navigate around obstacles, make turns, and accommodate different inclinations or heights. This flexibility allows for efficient rice transportation in various settings, such as rice mills, processing plants, and storage facilities.

Safety

Conveyor systems are designed with safety features to ensure the well-being of workers and prevent accidents. Emergency stop buttons, guards, and safety sensors are often incorporated into the conveyor design to protect operators and prevent injuries. Additionally, the automated operation of belt conveyors reduces the need for manual handling, minimizing the risk of strain or lifting-related injuries.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Xinxiang Dahan is a manufacturer specializing in the manufacture of rice belt conveyor. They have years of experience and technical expertise and are committed to providing high-quality, reliable conveying solutions. Xinxiang Dahan's rice belt conveyor adopts advanced design and manufacturing processes to ensure stable operation and efficient rice transportation. They focus on quality control and performance optimization of their products to meet customer needs and standards. Xinxiang Dahan provides customized services, designing and manufacturing rice belt conveyors suitable for various rice transportation scenarios according to customers' specific requirements and site layout. Their products have gentle handling properties that protect the integrity and quality of the rice. Xinxiang Dahan also focuses on customer satisfaction and provides comprehensive pre-sales and after-sales support to ensure that customers get the best experience and benefits during use.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.