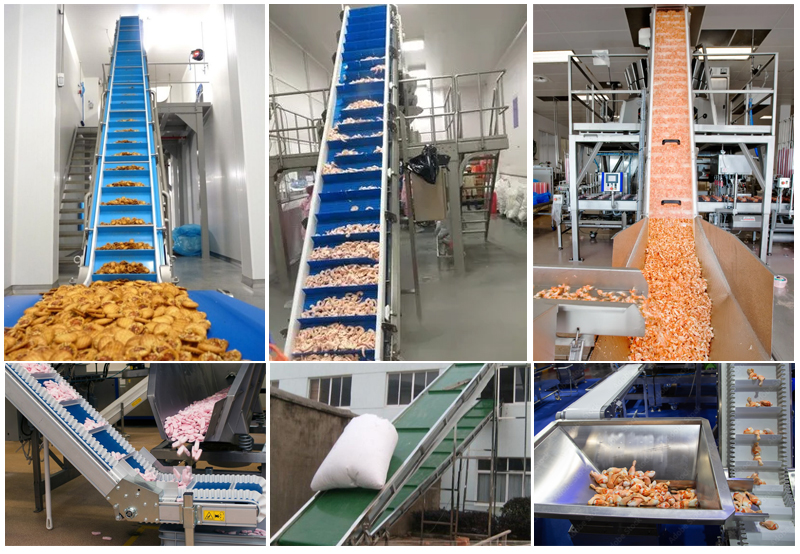

Conveyor systems specially designed for the food industry, used to transport all kinds of food, including raw materials, finished products and packaging materials.

![]()

![]()

Price:$980.00 - $7,800.00/Set

Consult now and enjoy a 10% discount

Belt material: food grade PVC

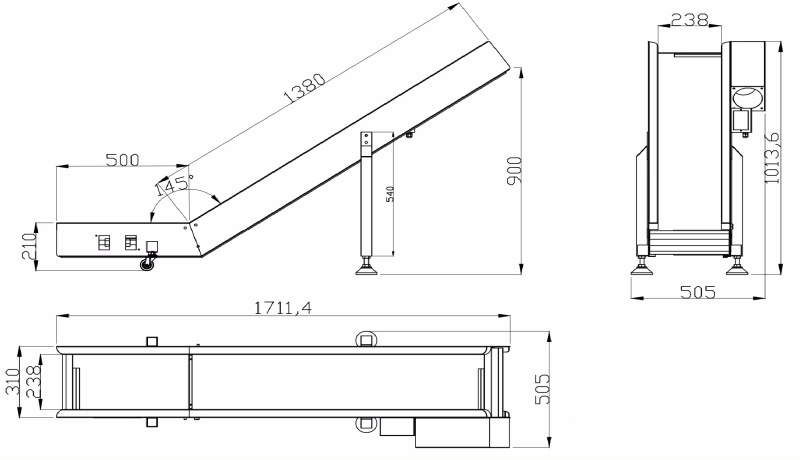

Belt width: 300-1500mm

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Conveying angle: 0-90°

Frame material: SUS304 stainless steel

Weight: 300 kg

Application: Used in the food industry to transport various food products such as cereals, fruits, vegetables, meat, baked goods, confectionery, bread, pastry, potato chips, biscuits, frozen food, snacks and beverages, etc.

Commitment:

Food grade belt conveyor is a conveying system specially designed and manufactured for the food industry to transport all kinds of food, including raw materials, finished products and packaging materials. They are commonly used in food processing plants, commercial kitchens and other food production facilities. , these conveyor systems are specifically designed to meet the stringent hygiene and safety standards required for food processing and handling operations.

The conveyor belt of a food grade belt conveyor is typically made of materials that are safe for use with food products, such as stainless steel, plastic, or rubber. These materials are easy to clean and sanitize, and do not pose a risk of contamination to the food being transported.

Foodgrade belt conveyors can be divided into the following four types according to different needs and application scenarios:

| Type | Flat Food Grade Belt Conveyor | Inclined or Declined Food Grade Belt Conveyor | PVCFood Grade Belt Conveyor | PE Food Grade Belt Conveyor |

| Image |  |

|

|

|

| Features | This is the most basic type of conveyor belt and consists of a flat surface, It is used for horizontal conveying of food raw materials or finished products and is suitable for continuous conveying in food processing production lines. | These conveyor belts are designed to move product up or down in an inclined or descending direction, which is useful for transporting product between different floors in a facility. | Polyvinyl chloride is used as raw material, and it is composed of polyester fiber cloth and polyvinyl chloride glue. Its working temperature is generally -10° to +80°, its joint method is generally a toothed joint, which is suitable for transmission in various complex environments. | Polyethylene is used as raw material, it is composed of polyester fiber cloth and polyethylene glue. Its working temperature is generally -20° to +80° , oil resistance, non-toxic hygiene, easy to clean and so on. The conveyor belt has good wear resistance and physical aging resistance. |

| Capacity and Length | 28-800m³/h 1.7-26 meters |

28-800m³/h 1.7-26meters |

28-800m³/h 1.7-26 meters |

28-800m³/h 1.7-26 meters |

Food grade belt conveyors are used to transport various food products in the food industry. Here are some common examples:

Raw materials: used to transport raw materials such as grains, fruits, vegetables and meat from storage areas to processing equipment.

Finished Products: Typically used to transport finished food products such as baked goods, confectionary, snacks and beverages to packing and distribution areas.

Dairy: Used to transport dairy products such as milk, cheese and yogurt from processing equipment to packaging and distribution areas.

Meat and Poultry: Typically used to transport meat and poultry products from processing equipment to packing and distribution areas.

Frozen food: Used to convey frozen food such as frozen fruits and vegetables, frozen pizza, frozen meals, etc. from the storage area to the packaging and distribution area.

Bakery Products: Used to transport bakery products such as bread, pastries and cakes from processing equipment to packaging and distribution areas.

Snack Food: Used to transport snack foods such as potato chips, cookies and pretzels from processing equipment to packing and distribution areas.

The working principle is to transport food from the starting point to the end point through the conveyor belt. The conveyor belt is suspended from the bracket, the driving device provides power, and the control system adjusts the speed and direction. The conveyor is designed to be waterproof and easy to clean to meet the hygiene requirements of the food industry. Safety devices such as protective covers and emergency stop buttons ensure operator safety.

Food Grade Belt Conveyor for Potato Chips

Food Grade Belt Conveyor for Peanut

Improve food safety

Food-grade belt conveyors are designed and manufactured to meet strict hygiene and food safety standards, helping to prevent contamination and ensure food is safe to eat.

Easy to clean and sanitize

Food-grade belt conveyors are made of materials that are easy to clean and sanitize, reducing the risk of contamination and ensuring food is safe to eat.

Wide range of applications

Conveyor belts are used to transport a wide variety of food products, including raw materials, finished products and packaging materials.

Reduce product damage

Conveyor belts transport food products gently and without damage, helping to maintain product quality and integrity.

Improve efficiency

Conveyor belts can move large quantities of food quickly and efficiently, reducing the need for manual labor and increasing the productivity of food processing operations.

Cost-effective

Conveyor belts can transport large quantities of food at a lower cost than manual labor, making them a cost-effective solution for food processing operations.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Food-grade belt conveyors are made up of multiple components that work together to transport food safely and efficiently. The following are the main components of a typical food grade belt conveyor structure:

Conveyor Belt: This is the main part of the conveyor and is made of food safe materials like PVC. The belt moves along a series of rollers or pulleys, which help guide the belt and maintain tension.

Frame: The frame provides support for the belt and helps keep it in place as it moves along the rollers. The frame is usually made of stainless steel or other food-safe material.

Motor: The motor provides the power to drive the conveyor belt, enabling it to move products from one place to another. The motor is usually located at one end of the conveyor and is attached to the pulleys or pulleys that move the belt.

Bearings: Bearings are used to support the rollers or pulleys that guide the conveyor belt. They help reduce friction and ensure smooth and efficient belt movement.

Rollers or Pulleys: These components guide the belt along its path and help maintain belt tension. They are usually made of stainless steel or other food-safe materials.

Below are some examples of some customization options for food grade belt conveyors to meet specific requirements:

Belt Material: Food-grade belt conveyors can be customized to use specific belt materials suitable for the type of food being transported. For example, a conveyor used to transport raw meat may require a different belt material than a conveyor used to transport baked goods.

Belt Width and Length: Belt width and length can be customized to meet specific application requirements. For example, a conveyor used to transport large boxes may require wider belts than a conveyor used to transport small packages.

Speed and Acceleration: The speed and acceleration of the conveyor belt can be customized to meet the requirements of a specific application. For example, a conveyor used to transport fragile items may need to run at a slower speed to prevent damage.

Inclined or Declined Angle: The angle of the belt can be customized to meet the requirements of a specific application. For example, a conveyor used to transport products between different floors of a facility may require a steeper incline or drop angle.

Controllers and Sensors: Food-grade belt conveyors can be customized with a variety of controllers and sensors to automate conveyor operations and keep them running safely and efficiently. For example, sensors can be used to detect when products are present on a conveyor belt and adjust the speed or direction of the conveyor accordingly.

Recommendations for selecting belt conveyors for conveying different types of food:

When choosing a belt conveyor that suits you, you can give priority to the characteristics, hygiene standards and conveying requirements of the food. The following are suggestions for selecting belt conveyors for different types of food:

Solid food: flour, grains, etc., you can choose a food-grade PVC belt conveyor, which has good wear resistance and food safety performance.

Fresh ingredients: Choose a belt conveyor with anti-slip function to avoid damage to the food during transportation.

Packaged finished products: It is recommended to use a food-grade blue PU belt conveyor, which is bright in color and easy to clean.Frozen food: Choose a belt conveyor made of low-temperature resistant food-grade materials to ensure stable performance in low-temperature environments.

Bulk food: You can choose a belt conveyor with a skirt design to avoid the problem of spilling during transportation.

A typical customer case of food grade belt conveyors is a large food processing company. The company uses food grade belt conveyors to transport and process food raw materials. This system uses materials and designs that meet food hygiene standards to ensure the hygiene and safety of materials. Conveyors are used to transport food raw materials such as flour, powdered sugar, and grains from different processes to processing equipment to ensure the continuity of the production line. Through automated control, conveyors can reduce manual operations and reduce the risk of food contamination.

Dahan belt conveyor manufacturer, we provide high-quality conveying equipment that meets food hygiene standards. Our food-grade belt conveyors provide a variety of options for different models and different materials to meet the specific needs of customers. They are made of food-grade PVC or PU materials and rubber materials. The price ranges from $980.00 - $7,800.00/set. If you have any needs recently, please contact us and we will send you a detailed price list!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.