Worm composting sieving machine is a specialized piece of equipment used in vermicomposting operations to separate composted material from worms, bedding, and other larger particles. This machine plays a crucial role in the efficient processing of vermicompost, which is a nutrient-rich organic fertilizer produced through the decomposition of organic waste by earthworms.

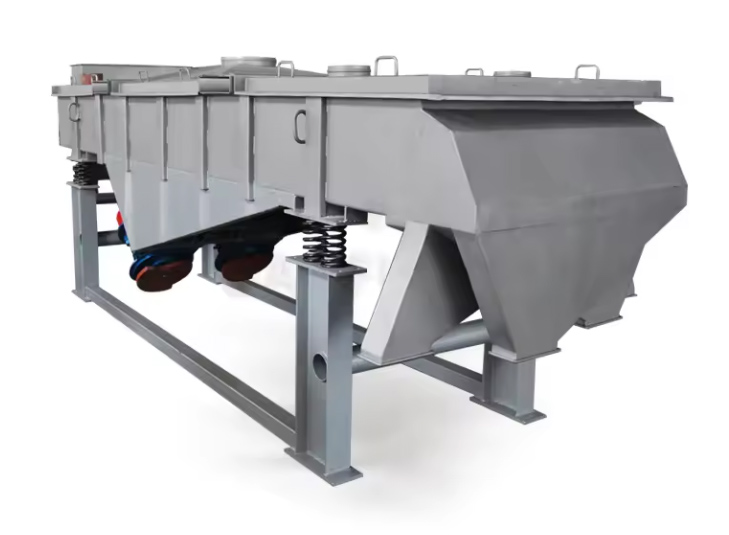

Sieve Drum: The sieve drum is the main component of the machine where the vermicompost mixture is fed for sieving. It contains perforated screens of varying mesh sizes that allow fine compost to pass through while retaining larger particles.

Motor and Drive System: The motor and drive system power the rotation of the sieve drum, causing the vermicompost mixture to move along the drum and separate into different fractions based on particle size.

Frame and Support Structure: The frame and support structure provide stability to the machine and hold the sieve drum in place during operation.

Inlet and Outlet Chutes: The inlet chute is where the vermicompost mixture is fed into the machine for sieving, while the outlet chute collects the sieved material for further processing or packaging.

Adjustable Legs: Some machines come with adjustable legs that allow operators to set the desired height and angle for optimal operation and material flow.

Control Panel: The control panel houses the controls for starting, stopping, and adjusting the speed of the machine. It may also include features such as timers and emergency stop buttons for safety.

Loading: The vermicompost mixture, which includes compost, worms, and bedding material, is loaded into the inlet chute of the machine.

Sieving Process: The motor is activated to rotate the sieve drum, causing the vermicompost mixture to move along the drum. As the mixture moves, the fine compost particles pass through the perforated screens, while larger particles such as worms and bedding are retained.

Separation: The sieved material is collected at the outlet chute, where it can be further processed, packaged, or stored for use as organic fertilizer.

Cleaning and Maintenance: After each use, the machine should be cleaned to remove any residual material and ensure optimal performance. Regular maintenance, such as lubrication of moving parts and inspection of screens, is essential to prolong the machine's lifespan.

Efficiency: The machine streamlines the process of separating vermicompost from unwanted materials, saving time and labor in vermicomposting operations.

Quality Control: By effectively sieving out larger particles, the machine helps produce high-quality, fine vermicompost suitable for use as organic fertilizer.

Increased Productivity: The machine allows vermicompost producers to process larger volumes of compost more efficiently, leading to increased productivity and output.

Resource Recovery: Separating worms and bedding material from the compost allows for the reuse of these components in the vermicomposting process, promoting resource recovery and sustainability.

Worm composting sieving machine is a valuable tool in vermicomposting operations, enabling efficient separation of composted material from worms and bedding. By automating the sieving process, this machine helps vermicompost producers enhance productivity, improve product quality, and promote sustainable waste management practices.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.