Sieving machine for vermicompost is a nutrient-rich organic fertilizer produced by earthworms and is a popular choice for organic gardening and farming. Screening vermicompost is an important step in the production process to ensure that the final product is high quality, consistent and safe to use.

1. Particle size control: Screen vermicompost to ensure consistent particle size distribution of the entire product. This is important to ensure that the fertilizer is evenly distributed and applied to the plants.

2. Purity: Screening the vermicompost helps to remove any impurities or foreign particles that may be present in the product. This is very important to ensure the quality and safety of fertilizer use.

3. Moisture control: Screening vermicompost helps remove excess moisture from the product, thereby reducing the risk of mold or bacteria growth.

4. Quality control: Screening vermicompost is an important step in the quality control process. It helps ensure that products meet required specifications and are consistent from batch to batch.

5. Uniformity: Screening vermicompost helps ensure that the final product is uniform and of consistent quality, which is important in ensuring that the fertilizer provides the intended effect.

Screening vermicompost can present some challenges that need to be addressed to ensure an efficient screening process and a high quality final product. Here are some common challenges of screening vermicompost:

1. Moisture content: The moisture content of vermicompost varies, which affects the efficiency of the screening process. If the moisture content is too high, vermicompost will clog the screen and reduce the screening efficiency. If the moisture content is too low, the vermicompost will become too dry to sift through.

2. Particle Size: Vermicompost has different particle sizes, which can affect the consistency of the final product and the efficiency of the screening process. Large particles can clog the screen, while fine particles can pass through the screen and affect the particle size distribution of the final product.

3. Sieve clogging: Vermicompost is very sticky and easily clogs the sieve, reducing the efficiency of the screening process and requiring frequent cleaning or maintenance.

4. Contamination: Vermicompost is easily contaminated by foreign matter such as stones, plastic or metal. This affects the purity and safety of the final product.

5. Machine wear: Vermicompost is abrasive and can cause severe wear to screening machines, reducing their efficiency and lifespan.

Trommel screens are commonly used to screen vermicompost because they are efficient and effective at separating large and fine particles. Here are some reasons why trommels are great for screening vermicompost:

1. High-throughput: It can process a large amount of vermicompost at one time, and is an effective choice for commercial-scale vermicomposting operations.

2. Uniform particle size distribution: It can make the particle size distribution of the sieved vermicompost consistent, which is of great significance to ensure that the fertilizer is evenly distributed and applied to plants.

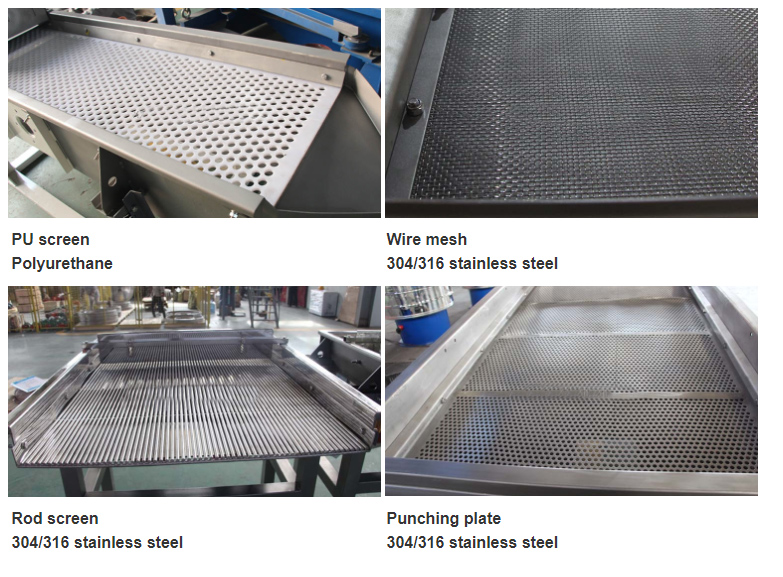

3. Customizable mesh size: It can be equipped with different mesh sizes to suit the specific needs of vermicomposting operations. This allows for greater flexibility in the screening process and helps ensure that the final product meets the required specifications.

4. Easy to clean and maintain: easy to clean and maintain, simple to control, easy to access the screen for cleaning and maintenance.

5. Durable: It is made of high-quality materials, durable and suitable for the requirements of vermicomposting process.

Overall, the trommel screen is an effective and efficient tool for screening vermicompost, providing a consistent particle size distribution and high throughput. By using trommel screens, vermicompost producers can ensure that their end products are of high quality, consistent quality and safe to use,

Address:China,Yanjin county forest park gate to the west 1000 meters north road.