The vibrating feeder can uniformly, quantitatively and continuously feed the block and granular materials from the storage bin to the receiving device, and is one of the equipments to realize the automatic production of the assembly line. Vibrating feeders are widely used in mining, metallurgy, chemical industry, building materials and other industries.

Vibrating feeders generate continuous vibrations through the vibration drive device, causing the material to jump in the conveying trough, thereby achieving uniform, continuous and automatic conveying of materials. There are different types of vibrating feeders, different types of vibrating feeders are suitable for different material conveying needs. This article will explain to you the models and parameters of different types of vibratory feeders.

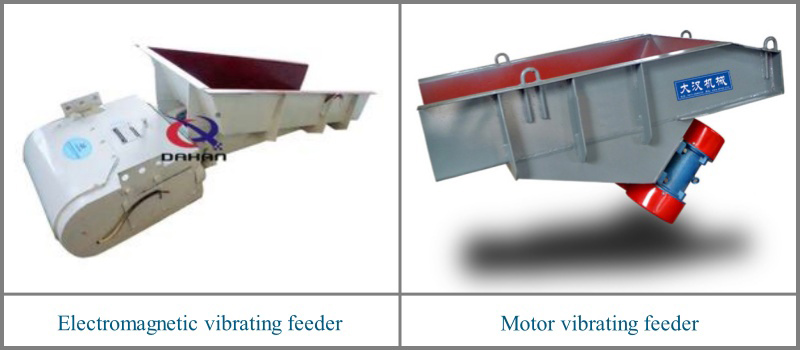

According to the different driving methods, it can be divided into motor type or electromagnetic vibration feeder:

This type of vibrating feeder uses a vibrating motor as the excitation source to drive the hopper to work. Amplitude: 2-5mm, vibration frequency: 96-1450 times/min, low maintenance cost, coarse screening can be performed during feeding, and the finished product can be improved. The quality of the material and the amount of feeding, the amount of feeding is large but not very accurate.

This vibrating feeder uses an electromagnetic exciter as the vibration source to drive the hopper to work. Amplitude: 1.5-3mm, vibration frequency: 700-3000 times/min. It is used for bulk, granular or powdery materials, quantitative or continuous feeding, the feeding amount is adjustable, and the feeding accuracy is high.

| Model | Productivity (t/h) |

Feed chute size (W*L*Hmm) |

Operation mode |

Feed particle size (mm) |

Vibration motor |

Weight (Kg) |

||||

|

Voltage (V) |

Frequency (Hz) |

Model |

Power (KW) |

Vibration frequency (times/min) |

||||||

| GZG30-4 | 15 | 300*1000*160 | Continuous | 120 | 380 | 50 | YZD2.5-4 | 0.18*2 | 1450 | 110 |

| GZG40-4 | 30 | 400*1200*160 | YZD5-4 | 0.25*2 | 155 | |||||

| GZG50-4 | 50 | 500*1200*160 | YZD8-4 | 0.4*2 | 190 | |||||

| GZG60-4 | 80 | 600*1800*180 | 180 | YZD16-4 | 0.75*2 | 410 | ||||

| GZG70-4 | 100 | 700*1800*200 | 180 | TZP20-4 | 1.1*2 | 440 | ||||

| GZG80-4 | 200 | 800*2000*225 | 200 | TZD32-4 | 1.5*2 | 640 | ||||

| GZG90-4 | 300 | 900*1500*300 | 250 | YZD50-4 | 2.2*2 | 730 | ||||

| GZG110-4 | 400 | 1100*1500*300 | 900 | |||||||

| GZG130-4 | 500 | 1300*1500*400 | 350 | 1000 | ||||||

| GZG70-6 | 80 | 700*1800*200 | 150 | YZD20-6 | 1.5*2 | 960 | 440 | |||

| GZG80-6 | 160 | 800*2000*225 | 180 | YZD30-6 | 2.2*2 | 670 | ||||

| GZG90-6 | 240 | 900*1500*300 | 240 | YZD40-6 | 3.0*2 | 740 | ||||

| GZG110-6 | 320 | 1100*1500*300 | YZD50-6 | 3.7*2 | > 940 | |||||

| GZG130-6 | 400 | 1300*1500*400 | 320 | 1040 | ||||||

| GZG150-6 | 500 | 1500*1800*500 | 2000 | |||||||

| GZG180-6 | 800 | 1800*1800*500 | YZD75-6 | 5.5*2 | 2590 | |||||

| ZG200-6 | 1000 | 2000*2000*500 | 360 | 3700 | ||||||

The model parameters of the vibrating feeder are introduced here. Vibrating feeders are widely used in mining, metallurgy, coal, building materials, light industry, chemical industry, electric power, grain and other industries to uniformly and quantitatively feed materials to receiving equipment such as crushing, coal preparation, screening, conveying, and packaging machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.