Telescopic belt conveyor is a kind of conveying equipment with telescopic function, which is usually used to adapt to different length requirements during material transportation. The stretchability of this conveyor allows it to flexibly adapt to various working environments and needs, improving the efficiency and convenience of material transportation.

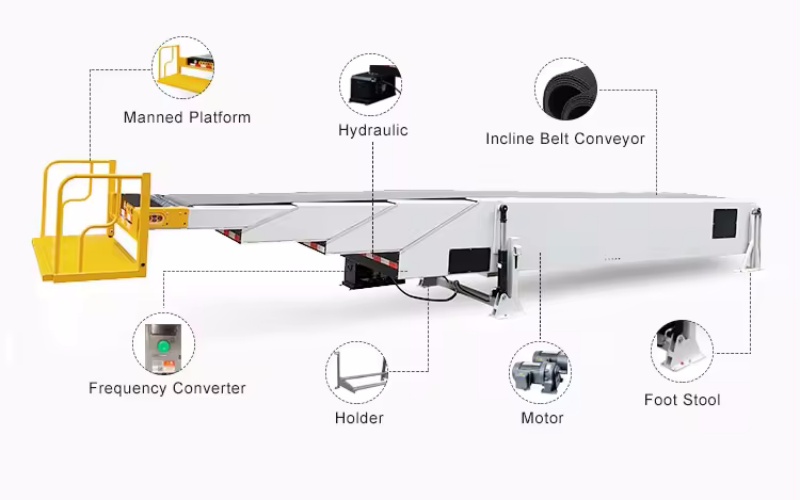

The telescopic belt conveyor carries materials through the conveyor belt, and the driving device drives the conveyor belt to move to realize the transportation of materials. The telescopic device is a key component that allows the length of the conveyor to be adjusted to suit different working scenarios. The bracket structure supports the conveyor belt and maintains stability. The control system controls the conveyor operation, and the safety devices ensure safe operation.

Generally speaking, a telescopic belt conveyor consists of a conveyor belt, a bracket structure, a telescopic device, a driving device and other parts. The conveyor belt carries the material and is driven by the driving device to realize the transportation of the material. The bracket structure is used to support the conveyor belt and maintain the stability of the conveyor. The telescopic device is a key component of the telescopic belt conveyor. The length of the conveyor can be adjusted as needed to adapt to different workplaces and material conveying distances.

Telescopic belt conveyors have many advantages in practical applications.

First of all, it can freely adjust the length according to specific needs, and is suitable for conveying materials of different lengths, improving work efficiency.

Secondly, the telescopic function makes it more flexible and suitable for various working environments, including factories, warehouses, docks and other places.

In addition, telescopic belt conveyors can also reduce manual operations, reduce labor intensity, and improve work safety.

Ship loading operations: Used at docks or ports to transport materials from shore to ships, adapting to the length and height requirements of different ships.

Warehouse logistics: used for material transportation inside the warehouse, and can be adjusted according to the height and location requirements of different shelves.

Construction site: Used at construction sites to transport construction materials, concrete and other materials from the ground to high altitude or long-distance locations.

Mining industry: Used for transporting ore, coal and other materials in mines to adapt to the distance requirements between different mining points.

Agricultural field: used for material transportation within farmland, such as transportation and stacking of crops, feed, etc.

First of all, the design and manufacture of telescopic devices need to take into account stability and durability to ensure that the conveyor can maintain stable operation during the telescopic process.

Secondly, regular maintenance and upkeep is essential to keep telescopic conveyors operating properly to avoid breakdowns and extend equipment life.

In general, the telescopic belt conveyor, as a flexible and efficient conveying equipment, has important application prospects in the field of material transportation. If you are interested in telescopic belt conveyors, you can contact us directly online and I will provide you with the best price.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.