A bag dust collector, also known as a baghouse, is a type of air pollution control device used in various industries to remove particulate matter from air or gas streams. It is an essential component in maintaining air quality and ensuring a safe working environment.

Filter Bags: These are the primary filtering elements of the dust collector. The filter bags are made of various materials such as woven or felted fabric, fiberglass, or synthetic materials. They are designed to trap dust particles while allowing clean air to pass through.

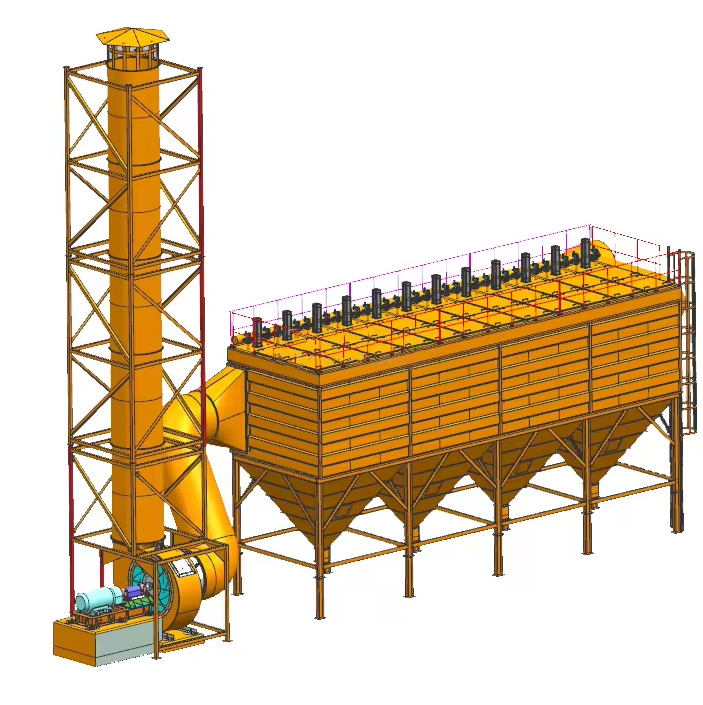

Housing: The housing of the baghouse encloses the filter bags and provides structural support. It is typically made of metal and contains inlet and outlet ports for air circulation.

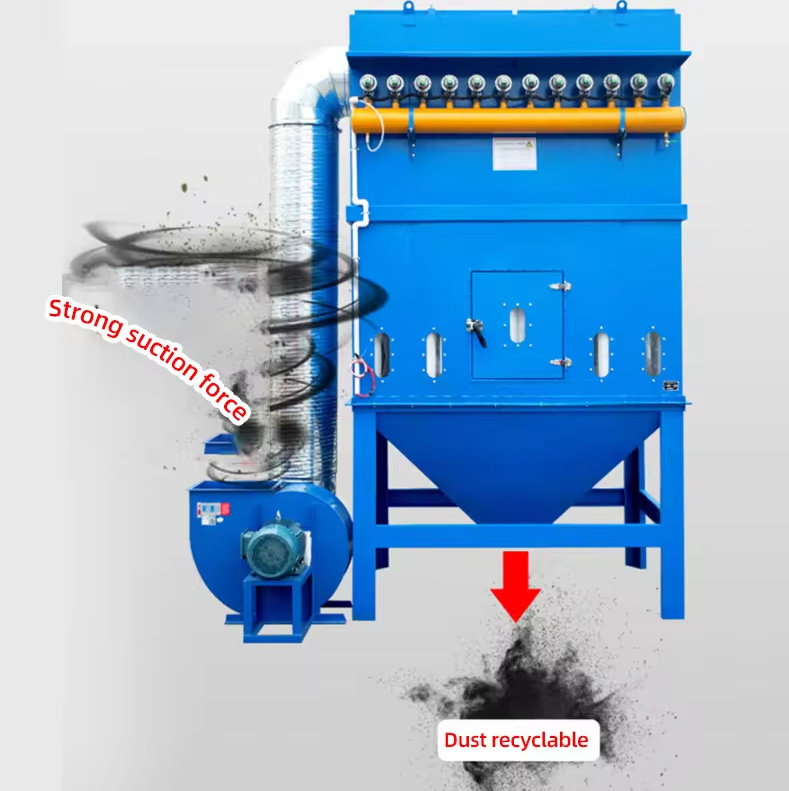

Cleaning Mechanism: Bag dust collectors have a cleaning mechanism to remove accumulated dust from the filter bags. Common cleaning methods include pulse-jet cleaning, reverse air cleaning, mechanical shaking, or sonic cleaning.

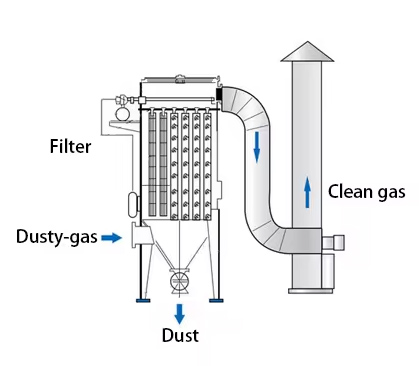

Inlet and Outlet Ducts: These ducts facilitate the entry of contaminated air into the dust collector and the exit of clean air after filtration.

Filtration: Contaminated air enters the baghouse through the inlet duct and passes through the filter bags. The dust particles are captured on the outer surface of the filter bags while the clean air passes through to the outlet duct.

Dust Accumulation: Over time, dust accumulates on the surface of the filter bags, forming a dust cake. This dust cake actually enhances the filtration efficiency by acting as an additional filter layer.

Cleaning Process: To prevent the filter bags from becoming clogged and maintain optimal airflow, the cleaning mechanism is activated periodically. Depending on the type of baghouse, this mechanism will remove the dust cake from the filter bags.

Dust Disposal: The removed dust falls into a hopper located at the bottom of the baghouse. From there, it can be collected and disposed of properly.

High Efficiency: Bag dust collectors are highly efficient in removing a wide range of particulate matter from air or gas streams.

Versatility: They can handle a variety of dust types and particle sizes, making them suitable for diverse industrial applications.

Cost-Effective: Baghouses have relatively low operating costs and require minimal maintenance compared to other dust collection systems.

Environmental Compliance: Bag dust collectors help industries comply with environmental regulations by reducing emissions and improving air quality.

Bag dust collectors are widely used in industries such as:

Metalworking: Including welding, grinding, and metal cutting processes.

Mining and Minerals: Handling of ores, coal, and other mineral materials.

Food Processing: Controlling dust in grain handling, milling, and food production facilities.

Pharmaceuticals: Ensuring clean air in pharmaceutical manufacturing processes.

Chemicals: Handling dust generated during chemical production and processing.

bag dust collectors play a crucial role in maintaining clean and safe working environments in various industries by effectively capturing and removing dust and particulate matter from air or gas streams. Their high efficiency, versatility, and cost-effectiveness make them indispensable tools for air pollution control and environmental protection.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.