Cyclone dust collectors and single-stage dust collectors are common industrial dust removal equipment used to remove solid particles in the air.

Cyclone:

Cyclone dust collectors use the principle of centrifugal force to separate dust particles from the air flow. After the dust-containing gas enters the cyclone, it enters along the tangential direction and forms a downward rotating airflow. Under the action of centrifugal force, the dust particles are thrown towards the cylinder wall and settle to the bottom, while the purified gas is discharged from the top.

Single stage dust collector:

Single-stage dust collectors mainly rely on gravity settling or inertial collision to separate dust particles. After the dust-containing gas enters the dust collector, the flow rate suddenly decreases, causing the dust particles to settle due to inertia or collide with the dust collector wall, thereby achieving dust separation.

Cyclone:

The cyclone dust collector is mainly composed of a cylinder, an air inlet pipe, an exhaust pipe, an ash discharge device and other components. The cylinder is conical or cylindrical and is the core component of the cyclone dust collector. The air inlet pipe is located at the top of the cylinder and is used to introduce dust-laden gas. The exhaust pipe is located at the top of the cylinder and is used to discharge the purified gas. The dust discharge device is located at the bottom of the cylinder and is used to collect settled dust.

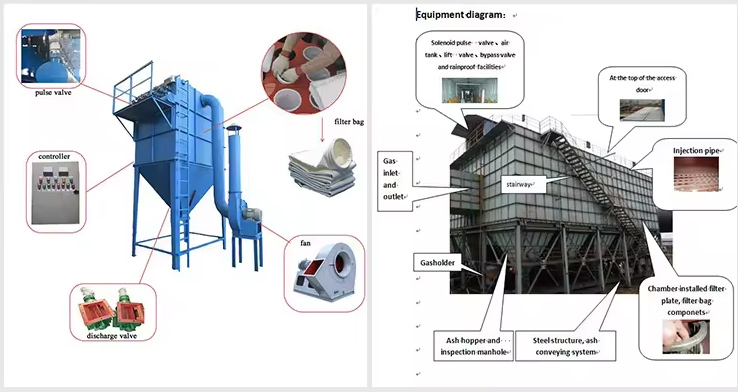

Single stage dust collector:

The structure of a single-stage dust collector is relatively simple and usually consists of a box, dust removal components and an exhaust system. The box is used to accommodate dust removal components and dust-containing gas. Dust removal components can be filter bags, filter elements, wet dust collectors, etc. The exhaust system is used to discharge the purified gas.

Cyclone:

The dust removal efficiency of the cyclone dust collector is related to factors such as cylinder diameter, air intake speed, and dust particle size. Generally speaking, the larger the cylinder diameter and the higher the air intake speed, the higher the dust removal efficiency. The dust removal efficiency of cyclone dust collector can usually reach 50%-90%, and the dust removal effect is better for fine particle dust.

Single stage dust collector:

The dust removal efficiency of a single-stage dust collector is related to factors such as the type, structure and material of the dust removal components. Generally speaking, the higher the filtration precision and the larger the filtration area of the dust removal element, the higher the dust removal efficiency. The dust removal efficiency of a single-stage dust collector can usually reach 70%-95%, and the dust removal effect is better for coarse-grained dust.

Cyclone:

Cyclone dust collectors are widely used in metallurgy, building materials, electric power, chemical industry, tobacco and other industries. They are suitable for dry and wet gases and can remove dust particles with a particle size greater than 5 μm.

Single stage dust collector:

Single-stage dust collectors are widely used in food, pharmaceutical, electronics, textile and other industries. They are suitable for dry, non-viscous gases and can remove dust particles with a particle size greater than 10 μm.

Cyclone dust collectors and single-stage dust collectors each have their own advantages and disadvantages. Which dust collector to choose should be comprehensively considered based on the actual situation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.