Ideal for small factories or workshops to remove dust and particulate matter

![]()

![]()

![]()

Price:$899.00-$2,500.00/Set

Consult now and enjoy a 10% discount

Model: DMC-32-112

Air volumn:1500-9000(m3/h)

Entrance gas temperature:≤120°C

Filter wind speed:1.00-1.80(m/min)

Entrance dust concentration: <200(g/m3)

Exitance dust concentration:≤50(mg/m3)

Application: Suitable for small factories, workshops and other environments, such as woodworking workshops, metal processing plants, food processing plants, etc.

Commitment:

Small industrial dust collector is also called mini industrial dust collector. Compared with other larger dust collector equipment, it is more convenient to operate. It can be operated by connecting the air duct and power supply because of its simpler structure, smaller size and footprint. It has less space and is mainly used for the discharge and dust collection at the top of the warehouse, the bottom of the warehouse, the top of the warehouse and various conveyors. If there is a special purpose, it can provide a single bag dust collector with temperature resistance and corrosion resistance filter material.

Small industrial dust collector models include DMC-24, DMC-36, DMC-48, DMC-64, DMC-80, DMC-96, DMC-120, DMC-200, DMC-300, etc. Generally, the filtration speed is 0. 5-2m/min, the efficiency of particles larger than 0.1μm can reach 99%, and the equipment resistance loss is about 980-I470Pa.

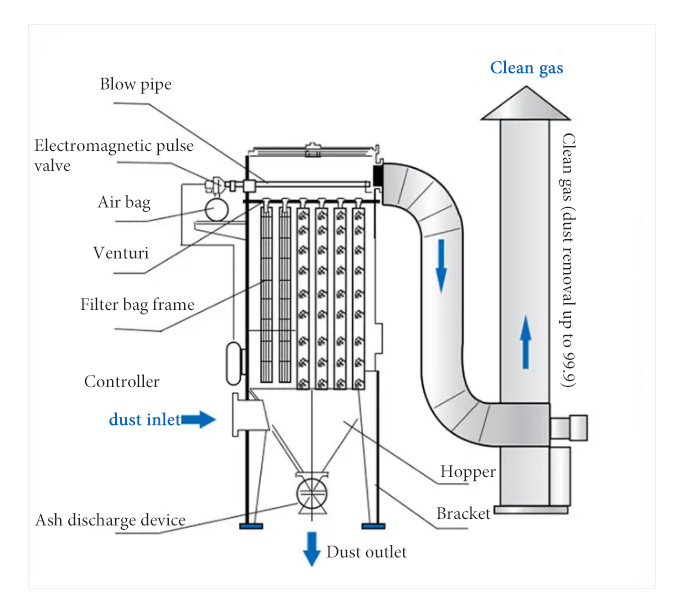

Small Bag Dust Collector: Bag dust collector is mainly composed of filter bags, filter bag frames, dust cleaning systems and air ducts. When working, dust enters the dust collector with airflow, passes through the filter bag, the dust particles are filtered out, and clean air is discharged through the outlet.

Small Cyclone Dust Collector: Uses the principle of centrifugal force to separate dust. When working, the dust in the air flow is separated by the centrifugal force through the rotation of the cyclone, and the clean gas is discharged from the central part of the cyclone.

The dust-laden gas enters the ash hopper of each sub-chamber from the air inlet flow pipe of the single-machine pulse dust collector, and under the diversion of the ash hopper diversion device, the large particles of dust are separated and directly fall into the ash hopper, while the finer dust is evenly distributed. It enters the middle box and is adsorbed on the outer surface of the filter bag. The clean gas enters the upper box through the filter bag, and is discharged into the atmosphere through each offline valve and exhaust pipe.

1. The filter bag is automatically cleaned by a mechanical vibration motor without expensive compressed air.

2. There is no noisy pulse jet cleaning during the operation of the equipment.

3. The standard acoustic fan chamber controls the fan noise to 74dB.

4. The filtration area is 110 square meters. Suitable for small to large airflow extraction.

Small industrial dust collector consists of filter chamber, filter bag, clean air chamber, ash hopper, ash discharge device, blowing ash cleaning device, and electric control system.

Clean air chamber: The clean air chamber module includes the flower plate, the ash cleaning system and the access door. The clean plenum module is designed as a factory pre-installed part to ensure matched installation and leak-free soldering.

Dust-containing air chamber: The dust-containing air chamber is the lower shell module of the dust collector, and the module contains filter parts, ranging from the top of the ash hopper to the flower plate. The dust chamber module is equipped with reinforcing ribs to ensure that it works under the design pressure. This is a factory pre-installed part to ensure installation matching and leak-free welding.

Filter bag: The top-loading spring expansion ring mouth filter bag adopts the form of top-loading spring expansion ring mouth, which can fully ensure the sealing between the filter bag and the flower plate. At the same time, this structure makes the installation and removal of the filter bag easier For convenience, no special tools are required, and special polymer membrane filter bags are used to provide stable and long service life under normal operating conditions.

| Type | DMC-32 | DMC-48 | DMC-64 | DMC-80 | DMC-96 | DMC-112 | |||||||||||||

| Air volumn(m3/h) | 1500-2100 | 2100-3200 | 2900-4300 | 4000-6000 | 5200-7000 | 6000-9000 | |||||||||||||

| Total filtering area(m2) | 24 | 36 | 48 | 60 | 72 | 84 | |||||||||||||

| Filter wind speed(m/min) | 1.00-1.50 | 1.00-1.50 | 1.00-1.50 | 1.10-1.70 | 1.20-1.70 | 1.20-1.80 | |||||||||||||

| Quantity of filter bag(piece) | 32 | 48 | 64 | 80 | 96 | 112 | |||||||||||||

| Entrance gas temperature (°C) | ≤120°C | ||||||||||||||||||

| Equipment resistance(Pa) | ≤1200 | ||||||||||||||||||

| Entrance dust concentration (g/m3) | <200 | ||||||||||||||||||

| Exitance dust concentration (mg/m3) | ≤50 | ||||||||||||||||||

| Dust with compressed air | Pressure(MPa) | 0.5-0.7 | |||||||||||||||||

| Gas consumption(m3/min) | 0.1 | 0.14 | 0.2 | 0.24 | 0.29 | 0.34 | |||||||||||||

| Under negative pressure (Pa) | 5000 | ||||||||||||||||||

| Quantity of pulse valve(piece) | 4 | 6 | 8 | 10 | 12 | 14 | |||||||||||||

| Fan power (kw) | 1.5 | 3 | 3 | 5.5 | 5.5 | 7.5 | |||||||||||||

| Weight (kg) | A (With ash hopper) | 1350 | 1620 | 1850 | 2360 | 2800 | 3200 | ||||||||||||

| B(Without ash hopper) | 1220 | 1470 | 1670 | 2150 | 2540 | 2880 | |||||||||||||

Our small industrial dust collectors provide the best filtration performance in a wide range of industrial applications, filtering dust from fine dust to large dust, and have been widely used in mining, electric furnace smelting, machinery manufacturing, chemical products, cement building materials, and grain processing industries warehouse top, warehouse bottom, belt transport gate and local dust removal, etc.

Small industrial dust collectors play an important role in various industrial scenarios:

In woodworking workshops, wood chips and dust are common products, and small industrial dust collectors can effectively remove these wood chips and dust.

In metal processing plants, small industrial dust collectors can effectively capture these fine metal particles to prevent contamination and harm to workers' health.

In food processing plants, dust and odors are generated during food processing, and small industrial dust collectors can help remove these dust and odors.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.