Industrial screener is a key equipment used for screening and grading materials. It is widely used in many industrial fields, such as mining, metallurgy, chemical industry, building materials, food, medicine, etc. Its main function is to separate raw materials according to different particle sizes to meet different process requirements and product quality standards. The industrial screener is efficient, precise and reliable, and plays a vital role in improving production efficiency and product quality.

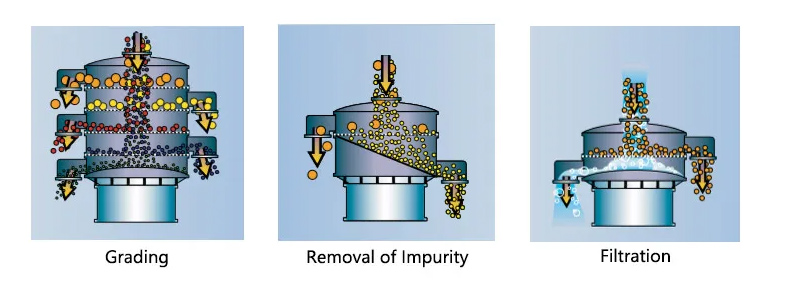

The working principle of the industrial screener is based on the vibration or rotational movement of the material. It usually consists of a screen box, a screen, a driving device and a supporting device. The material enters the screen box through the feed port. Under the action of the screen, it is subject to vibration or rotational force, causing the material to move relative to the screen. Materials with smaller particle sizes pass through the sieve holes, while materials with larger particle sizes are blocked on the screen, thereby achieving material separation and classification.

According to different working principles and structural characteristics, industrial screeners can be divided into many types. Common types include vibrating screens, rotary screens, airflow screens, etc. Vibrating screening machines use vibration force to screen materials on the screen; rotary screening machines separate materials through rotational motion; air flow screening machines use the action of airflow to classify materials. Each type of screening machine has its applicable material range and specific process requirements. Users can choose the appropriate type according to actual needs.

Industrial screeners are widely used in various industrial fields. In the mining and metallurgical industries, it is often used for screening of ores, tailings processing and coal classification; in the chemical and building materials industries, it can be used for the separation and screening of granular materials; in the food and pharmaceutical industries, it is often used Screening of food powders and grading of drugs, etc. The application range of industrial screener is very wide, covering almost all industrial fields that require screening and classification of materials.

The industrial screener has obvious advantages over traditional manual screening. First, it enables efficient and continuous material handling, greatly improving production efficiency. Secondly, the industrial screener has precise screening capabilities and can adjust the screen hole size and screening accuracy as needed to ensure product quality and consistency. In addition, the industrial screener also has automatic control functions, which can achieve precise control of the screening process by adjusting parameters such as vibration frequency and amplitude. These advantages make the industrial screen an indispensable and important equipment in modern industrial production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.