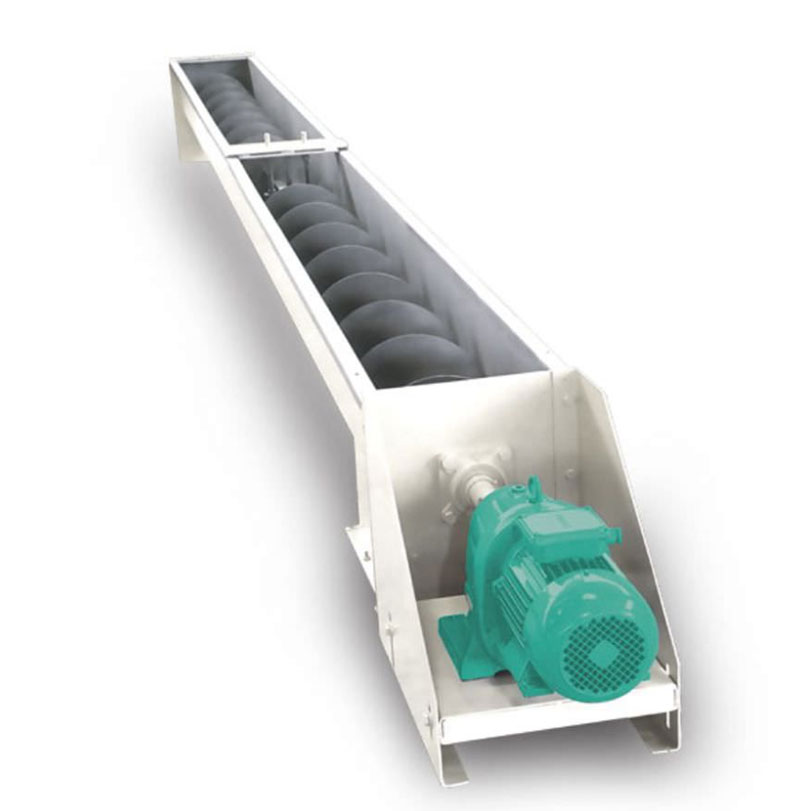

Shaftless screw conveyor is a common conveying equipment in screw conveying equipment, which has the characteristics of strong anti-winding, large output and low energy consumption. It has the following advantages and disadvantages.

1. To prevent winding: Sludge is a solid sediment produced by water and sewage treatment process, which has strong viscosity, and the sludge also contains some other types of sundries and massive stones. If you use ordinary shaft screw For conveyors, it is very easy to break the screw blade or the material sticks to the blade, not to mention affecting the conveying efficiency, and it will cause damage to the machine in the long run. The shaftless screw conveyor adopts the design of no central shaft, which can fundamentally solve this problem. a question.

2. Tight sealing and no material leakage: Because the sludge contains a certain amount of water, it has fluidity. If the seal is not tight during the transportation process, the material will leak, and it will also cause the material to enter the bearing chamber and cause damage to the machine. The shaft screw conveyor adopts fully enclosed conveying and easy-to-clean screw surface, which can ensure that the material does not leak, reduce environmental pollution and damage to the machine.

3. Large output and long conveying distance: For sludge conveying, users are also more concerned about the conveying efficiency of the equipment. The torque of the shaftless screw conveyor can reach 4000N/m, and the conveying length of a single machine can reach 60 meters. The conveying capacity is limited. 1.5 times that of the shaft. In addition, according to the needs of users, multi-stage series installation can be used to transport the sludge over a long distance.

1. Limited conveying distance: Since the shaftless screw conveyor adopts direct drive, the conveying distance is limited, which is suitable for small-scale conveying.

2. Difficult to adapt to high temperature, corrosion and viscous materials: Due to the limited material selection and manufacturing process of the rotating parts and sealing devices of the shaftless screw conveyor, it cannot adapt to the requirements of high temperature, strong corrosion and extremely viscous material transportation.

3. High maintenance cost: the repair and replacement cost of the shaftless screw conveyor is relatively high, and professional and technical personnel are required for maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.