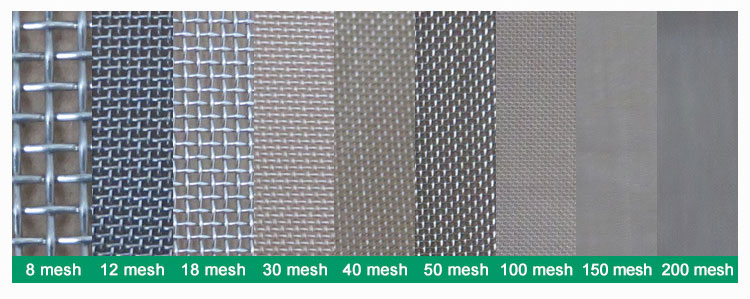

Grain Sieves are a screening device widely used in laboratories and industry. It has meshes of different sizes and frame structures to allow different types of screening tests to be performed. Sieve size refers to the hole size of the sieve. Different sieve sizes are suitable for different sieving requirements. Choosing the appropriate sieve size can ensure screening results and production efficiency.

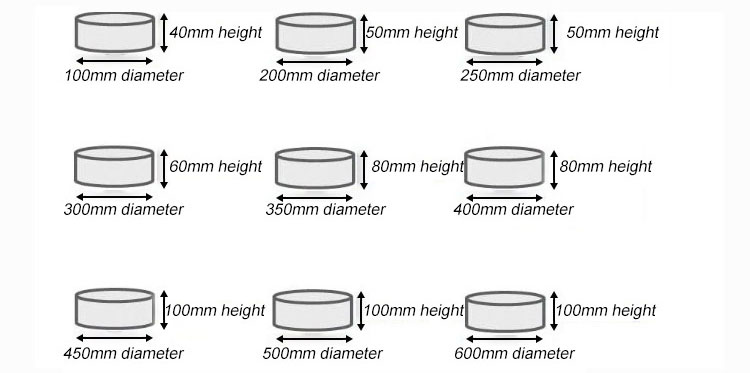

In industrial production, it is crucial to select the appropriate sieve size according to the characteristics and requirements of different materials. Sieves of special sizes can also be customized according to specific sieving requirements and material characteristics. Customized sieve sizes can be designed based on particle size, shape, density and other characteristics to meet specific sieving needs and improve screening efficiency and accuracy. Below are several common test sieve sizes.

Standard sieve sizes, also known as ISO sieve sizes or ASTM sieve sizes, are standard sieve sizes commonly used in industrial production and scientific research. This sieve size has a fixed screen aperture and frame architecture. The ISO specification has a sieve diameter of 100mm, while the ASTM specification has a sieve diameter of 8 inches (approximately 203mm). Standard sieve sizes feature a uniform screen aperture and frame architecture for a wide range of applications.

Micro test sieves are usually smaller in size than standard sieves and are mainly used for fine screening and laboratory research. These screens are usually made of stainless steel and are usually under 3 inches (about 76 mm) in diameter. Micro test sieves are often used for high-precision screening, for example when screening fine particles in the field of powders.

Vibrating test sieves separate processed samples into particles of different sizes through mechanical vibration. The sieves are available in a variety of sizes and shapes, allowing flexibility for specific applications. The screen holes in the vibrating test sieve are usually round or square and can be replaced as needed. Vibrating test sieves can be used to separate a variety of powdery materials such as cement, stone, gypsum, fertilizers, etc.

Diameter sieves are sieves with special spherical and oval openings, capable of handling granular materials. The sieve hole of the diameter sieve is composed of many small balls and filter components in series, and finally the raw material is screened into particles of the required size. Diameter sieves are commonly used in the processing of coffee beans, wheat flour, flour, malt and other materials.

In summary, the nature and field of screening tests dictate the size and shape of the test sieve. Different screen sizes have different advantages and limitations for specific screening applications. Understanding the different sieve sizes and their applications is key to conducting screening trials. Our manufacturer produces different types of sieves with different diameters. If you want to learn more about our sieves, please click to chat online or view our product page.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.