For laboratory classification and particle size determination of powders, bulk granules and suspensions

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

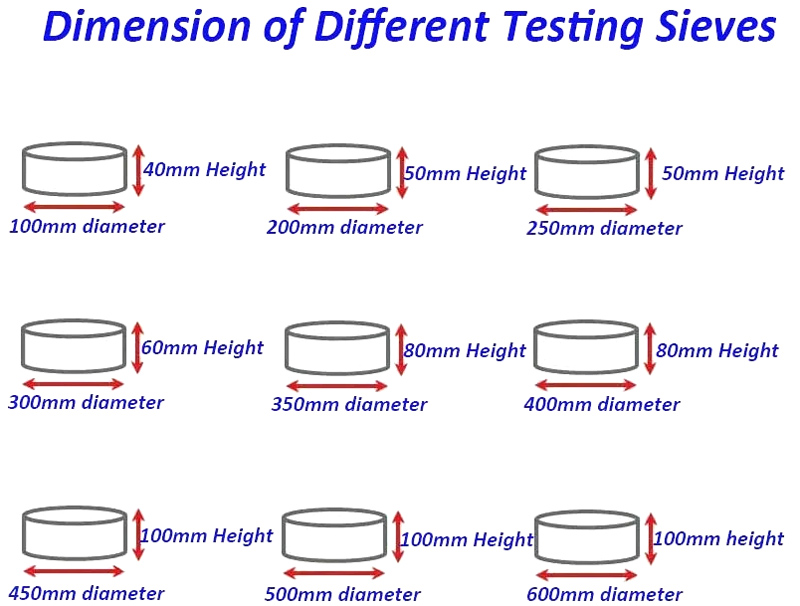

Frame diameter:500/400/300/200/120/80/75mm,or others as your requirements.

Surface type:Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Aperture sizes:0.02-2.36mm

Hole shape:Square/Round

Material:Stainless steel304/Brass/Chromeplate

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

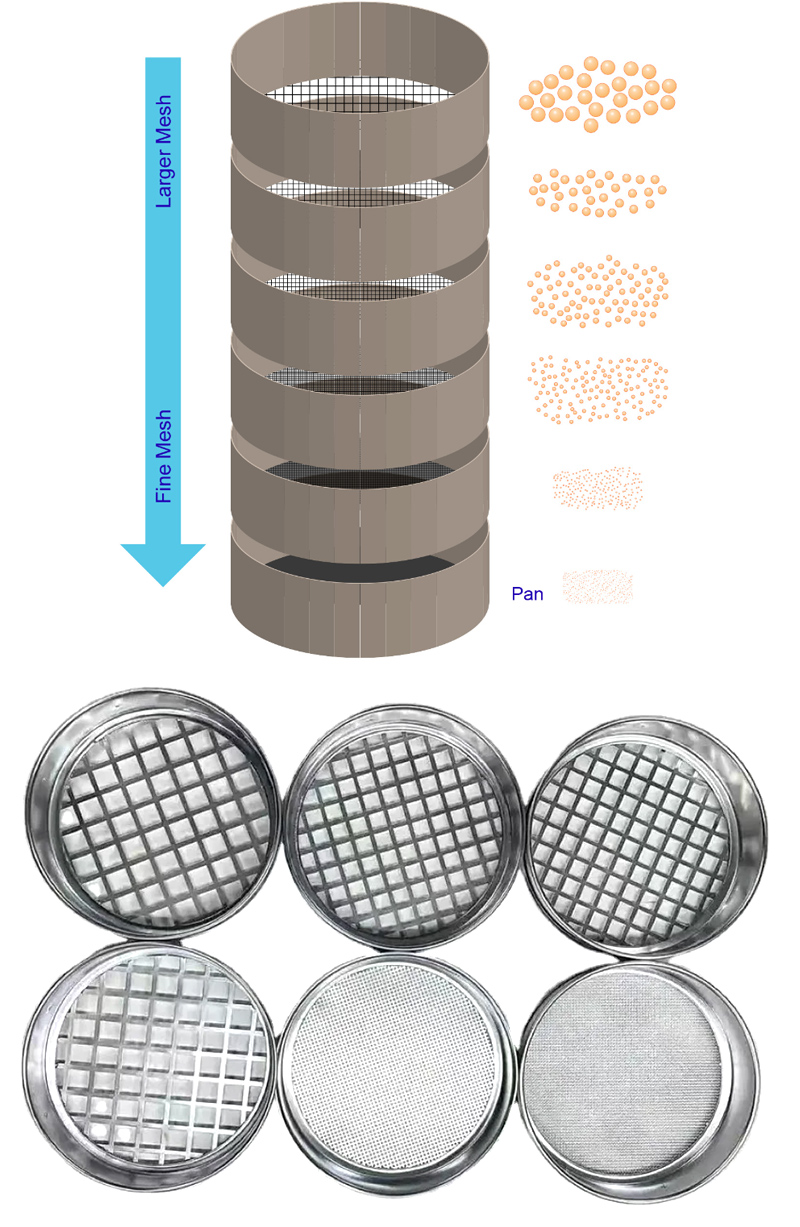

A sieve test is a method used to determine the particle size distribution of a granular material. It involves passing the material through a series of sieves with progressively smaller openings. The sieves are stacked in order of decreasing mesh size, with the finest sieve at the bottom and the coarsest sieve at the top. The material is placed on the top sieve, and mechanical or manual agitation is applied to facilitate the passage of particles through the sieves.

Sieve tests are commonly used in various industries, such as construction, mining, agriculture, and pharmaceuticals, to assess the quality and consistency of granular materials. The results can be used to determine if the material meets specifications, to monitor and control production processes, and to optimize material properties for specific applications.It can quickly and efficiently measure solid particle sizes from 125mm to 20μm. Special sieves with apertures less than 20 μm can be used. The finer the sieve, the easier it is for certain types of solid particles to block or clog the pores. In response to this situation, we have designed an electromagnetic test sieve that can perform "micro" screening. Points up to 5μm.

Sieve tests are divided into three types, each with different characteristics and application scope:

1. Metal wire braided mesh: widely used, with mesh openings ranging from 2.36 mm to 0.02 mm, only square mesh.

2. Perforated plate mesh: It is mainly used for large meshes, with round holes and square holes, ranging from 0.2 to several hundred millimeters.

3. Electroforming mesh: It is mainly used in high-precision situations, and can ensure that each mesh is within the average error range.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

1. Preparation work: Make sure the standard sieve and screen mesh are clean and intact, and prepare samples of the material to be tested.

Assemble the screen: Select the appropriate screen size and hole diameter, and install the screen on the standard screen. Typically, a standard screen consists of a series of stacked screens with gradually decreasing apertures from top to bottom.

2. Place the sample: Place the sample of the material to be tested on the top screen. Make sure the sample is evenly distributed on the screen and avoid piling up or over-compaction.

3. Screening process: Place the standard sieve on the screening equipment, such as a vibrating screen or screening machine. Start the equipment and allow the sample to be sieved on the screen.

4. Complete screening: After the screening process is completed, close the screening equipment and remove the standard screen. Check the amount of sample residue on each screen and record it.

Standardization

Sieve test is designed and manufactured according to international or industry standards, with uniform specifications and dimensions, thus ensuring the comparability and consistency of test results.

Data is reliable

A variety of different mesh sizes are provided to adapt to the screening needs of materials in different particle size ranges, and can quickly and effectively measure solid particle sizes from 125mm to 20μm.

Multi-layer detection

Samples of different sizes are separated through a stack of sieves of different sizes, which can be used individually or stacked up to 8 layers.

Easy to use

It is simple to operate and does not require complex equipment or technology. Simply place the materials to be screened on top of the screen and gently shake or vibrate the screen to complete the test.

Traceability

The manufacture and use of sieve testts follow specific standards and procedures. This makes test results traceable and can be compared and verified with other laboratories or institutions.

Cost effective

The cost of use is low and no additional maintenance and operating costs are required. In addition, the standard test sieve operates at a faster speed and can complete the test in a shorter time, improving work efficiency.

Sieve test uses YZU vertical vibration motor as the vibration source of the whole machine. The upper vibration plate is driven by the vibration motor to vibrate, and then transmitted through the vibration plate to the Φ200 screen frame placed on the upper part of the vibration plate. The material particles smaller than the aperture of the screen are sieved to the lower screen frame, so that only materials of the same particle size are left in each test screen to achieve the separation of different particle sizes and determine the particle size composition of the material to make the Φ200 screen frame The materials in can be very effective for filtering, grading and sieving purposes.

| Mesh number | Mesh size | Mesh number | Mesh size |

| diameter 200mm,300mm,400mm | |||

| 8# | 2.360 | 80# | 0.180 |

| 10# | 2.000 | 100# | 0.150 |

| 12# | 1.700 | 120# | 0.125 |

| 14# | 1.400 | 140# | 0.106 |

| 16# | 1.180 | 150# | 0.1 |

| 18# | 1.000 | 170# | 0.09 |

| 20# | 0.850 | 180# | 0.08 |

| 25# | 0.710 | 200# | 200# |

| 30# | 0.600 | 230# | 0.063 |

| 35# | 0.500 | 250# | 0.06 |

| 40# | 0.425 | 270# | 0.053 |

| 45# | 0.355 | 325# | 0.045 |

| 50# | 0.300 | 363# | 0.04 |

| 60# | 0.250 | 400# | 0.038 |

| 70# | 0.212 | 500# | 0.025 |

| diameter 200mm,300mm | |||

| 635# | 0.020 | 700# | 0.018 |

| 800# | 0.015 | 1000# | 0.01 |

| 1250# | 0.005 | 1800# | 0.003 |

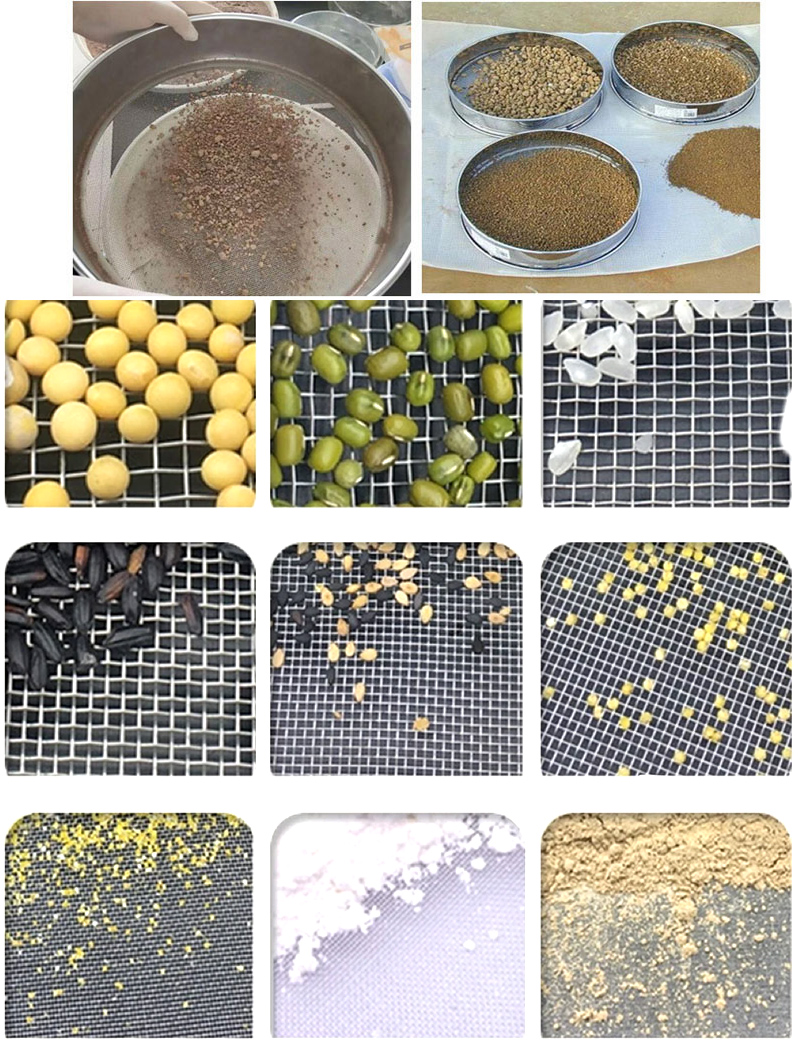

The sieve test finds application in various industries and fields. Some common applications of the sieve test include:

Construction industry: In the construction industry, the sieve test is used to analyze the particle size distribution of aggregates such as sand, gravel, and crushed stone. This information helps in determining the suitability of aggregates for different construction applications, such as concrete, asphalt, and road base.

Mining and minerals: The sieve test is widely used in the mining and minerals industry to analyze the particle size distribution of ores, minerals, and mineral powders. It helps in assessing the efficiency of grinding and milling processes, optimizing mineral processing operations, and ensuring the desired particle size for downstream applications.

Pharmaceutical industry: In the pharmaceutical industry, the sieve test is employed to analyze the particle size distribution of powders used in drug formulation and manufacturing. It ensures that the powders meet the required specifications for dosage uniformity, dissolution rate, and flowability. The sieve test is also used for quality control of excipients and active pharmaceutical ingredients.

Food industry: The sieve test is used in the food industry to analyze the particle size distribution of food ingredients, such as flour, sugar, spices, and powders. It helps in ensuring consistency in product quality, texture, and performance. The sieve test is particularly important in industries like baking, where the particle size of flour affects the dough's properties and the final product's quality.

Environmental monitoring: The sieve test is employed in environmental monitoring and soil analysis to determine the particle size distribution of soil samples. It helps in assessing soil fertility, texture, and suitability for various applications, such as agriculture, landscaping, and construction. The sieve test is also used in sediment analysis to evaluate the composition of sediments in rivers, lakes, and coastal areas.

Research and development: The sieve test is extensively used in research and development activities across various fields, including materials science, geology, chemistry, and engineering. It aids in studying the behavior of granular materials, characterizing powders, developing new materials, and optimizing processes.

The following are specific applications:

| Product | Mesh size | Product | Mesh size | Product | Mesh size |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | Soybean | 4-5 mesh | Green beans | 10 mesh |

| Rice | 12-14 mesh | Rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| Flour | 50-60 mesh | Cereals | 40-50 mesh | Sesame | 22-24 mesh |

| Fried Chicken Burger Bread | 20-30 mesh | Mung bean powder | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine Pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Chinese Herbal Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Dregs | 60-150 mesh | Soy milk | 80-120 mesh | Honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

Since its establishment in 2008, it has relied on the high quality of its products, technical expertise, and high-quality services to adapt to customer needs, and has been highly recognized by customers. Its products are widely used in abrasives, soil grinding, metallurgy, pharmacopoeia, metallurgy, chemical industry, Accurate measurement of the particle size structure, liquid solid content and debris content of granular and powdery materials in scientific research and production, laboratories, quality inspection rooms and laboratories of universities and colleges in medicine, powder, building materials, national defense, geology and other departments. Screening, filtering, testing. It is also often researched and used by Coca-Cola (China) Beverages Co., Ltd., Tsinghua University, North China University of Water Conservancy and Hydropower, Hainan Tropical Ocean Institute, Shanghai University, Lanzhou University and other units.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.