Edible sugar can be divided into: raw sugar, white sugar, brown sugar, cube sugar, rock sugar, etc. Sugar production process: extraction of cane juice → purification of sugar juice → concentration and evaporation of sugar juice → crystallization of syrup → separation → drying → packaging. Generally, sugar sifter shaker should be used for strict screening, impurity removal, grading, etc. before packaging. In order to ensure that the finished edible sugar particles are uniform, no agglomeration, no clumping phenomenon, and improve its edible quality and taste. The sugar sifter shaker used in this entire process is generally used before the packaging scale.

When the specific gravity of powdered sugar is 0.5-0.8, DH-800-1S sugar sifter shaker is used, and the processing capacity of the 100-mesh sieve per hour is 200kg.

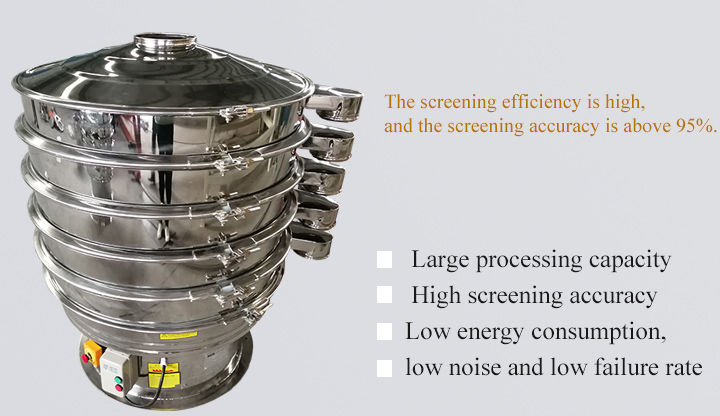

1. Large processing capacity and high screening accuracy.

2. Good sealing performance, fully enclosed dust does not fly

3. Easy to disassemble, easy to clean inside and outside, no hygienic dead corners, all parts in contact with materials are made of standard SUS304 stainless steel, in line with food-grade GMP specifications

4. The discharge port can be adjusted arbitrarily in 360 degrees, and it is convenient to connect with the scene

5. No blockage of the screen, special cleaning device, which is conducive to quick and convenient cleaning of residual materials on the screen

6. Low energy consumption, quick start, low noise and low failure rate.

7. It can be used in single-layer and multi-layer according to the actual production needs, one-time multi-stage screening, impurity removal, etc.

The sugar sifter shaker uses a vertical vibration motor as the excitation source. There are eccentric blocks installed on the upper and lower ends of the motor. Adjusting the phase angle of the eccentric blocks can convert the rotational motion of the motor into horizontal, vertical, and inclined three-dimensional motion. This resultant force is transmitted to the material on the screen surface, effectively separating the above-screen material and the under-sieve material from different discharge ports.

For screening, removing impurities and grading powdered sugar, you can use a sugar sifter shaker. Contact Dahan Machinery immediately to recommend suitable models and detailed quotations for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.