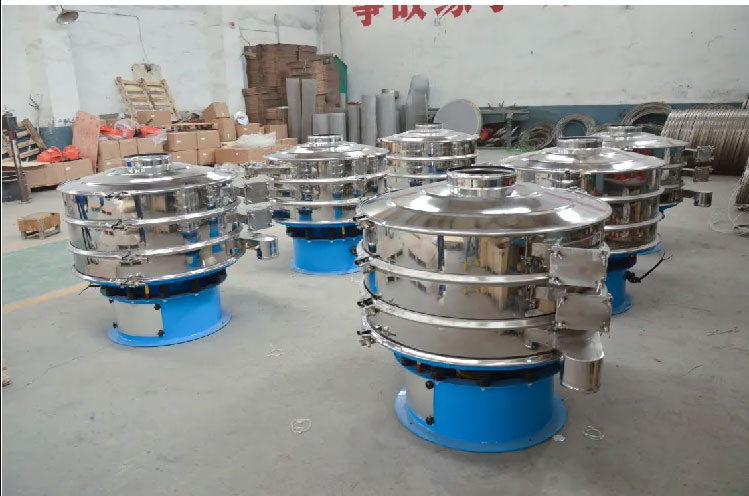

Vibrating screen for brown sugar is a specialized equipment used in the sugar processing industry to separate and classify brown sugar particles according to their size. By using vibrating screen, brown sugar processing industry can effectively remove impurities from sugar products such as dust, fiber and Larger particles, ensuring its quality and consistency. It also helps separate particles of different sizes to meet specific applications or packaging requirements.

The mesh size selected for the vibrating screen for brown sugar will vary according to specific application requirements. Under normal circumstances, the mesh size commonly used in brown sugar vibrating screens is generally between 40 mesh and 80 mesh.

Vibrating screen for brown sugar commonly used screen sizes can vary based on specific application needs. In general, the choice of sieve depends on the desired brown sugar particle size range and screening effect.

The following are some common screen size ranges commonly used in vibrating screens for brown sugar:

Coarse screen: The commonly used screen size range is from 10 mesh (the larger the mesh number, the smaller the aperture) to 30 mesh, that is, the opening size is about 2.0 mm to 0.6 mm.

Medium screen: The commonly used screen size range is 40 mesh to 60 mesh, that is, the opening size is about 0.4 mm to 0.25 mm.

Fine screen: Commonly used screen sizes range from 80 mesh to 120 mesh, that is, the opening size is approximately 0.18 mm to 0.125 mm.

A vibrating screen for brown sugar is commonly used in the sugar processing industry for several purposes:

Size classification: The vibrating screen helps classify brown sugar particles based on their size. It separates the sugar into different fractions, such as coarse, medium, and fine, according to specific size ranges. This classification ensures consistency in the final product and helps meet the desired particle size specifications.

Impurity removal: The vibrating screen effectively removes impurities from brown sugar, such as dust, fibers, and larger particles. The vibration and sieving action of the screen allow smaller particles and impurities to pass through the mesh, while larger particles and impurities are retained on the surface of the screen. This helps improve the quality and purity of the brown sugar.

1. The screening accuracy is as high as 90-95%, and the output is 5-10 times that of the vibrating screen. With the addition of a cleaning device, the screen holes are not easy to block.

2. Made of SUS304 or 316L stainless steel, polished inside and outside, not easy to rust, can prevent brown sugar from being polluted, suitable for industries with high hygiene requirements such as food and medicine.

3. The production process of sugar has high requirements, and it often needs to be clean and hygienic and the particles are uniform. However, the viscosity of sugar is easy to break, which increases the difficulty of screening. There is no vibrating screen specially designed for sugar screening. High-speed vibration will not damage the shape of the product, greatly improving the yield of materials, suitable for screening of fragile materials.

4. Internal sealing, airtightness up to 50 mPa, rubber tension spring left and right tension support, good shock absorption and buffering effect, working noise can be as low as 75dBa.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

| Particle feed size: | 1 micron up to 20 mm | ||||||

| Feed rates: | 1kg/h – 50 ton/h | ||||||

| Bulk densities: | 20 – 10000 grams/liter | ||||||

| Mesh openings: | 20 microns to 20 mm | ||||||

| Screens usable: | 304, 316L, or 430 stainless steels or plastic wire mesh fabric, perforated plates | ||||||

| No. of screen decks: | 1 – 6 per machine | ||||||

| Anti-blinding systems: | – Rubber balls | ||||||

| – Rotating roller brush arms | |||||||

| – Rotating air-jet nozzle arms | |||||||

| – Ultrasonic | |||||||

| – Combinations | |||||||

| Speed range: | 180-280 min-1 | ||||||

| Screen movement: | Three-dimensional, set to product | ||||||

| Amplitude: | 40-80 mm horizontally and 5-40 mm vertically | ||||||

| Acceleration: | 1,3-1,8 g | ||||||

| Model sizes/ca. Ø: | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Screening surface (m²): | 0.292 | 0.785 | 1.13 | 1.83 | 2.63 | 4.52 | 5.31 |

| Motor power (kW): | 0.25 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 5.5/7.5 |

| Materials: | Carbon steel, Stainless and Special steels | ||||||

| Surfaces: | Painted, brushed or ground, mirror or electro polished, and ViwateQ options for Food and Pharmaceutical products with a surface roughness of < 0.4 microns (GMP, FDA compliant). | ||||||

By utilizing the combination of sieving and vibration, the vibrating screen effectively removes impurities from the brown sugar, ensuring a high-quality and pure sugar product. It helps to enhance the cleanliness, consistency, and overall quality of the brown sugar by eliminating unwanted particles and contaminants.If you are looking for vibrating screen equipment, I recommend you contact Dahan Machinery Company. They specialize in providing customized screening solutions and can design the right vibrating screen for you based on your project needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.