The production of medicinal granules is based on the decoction requirements of medicinal decoction, and the production process rules are formulated according to different varieties. Particle screening and packaging.

Pharmaceutical raw material screening

All raw materials for the production of formula granules are high-quality raw materials, and the selection of pharmaceutical raw materials is very important. The pharmaceutical raw materials are purified and sorted through a linear sieve to remove impurities to ensure the quality of pharmaceutical raw materials; DZSF linear vibrating screen is recommended!

Fine powder screening

The dried fine powder is sieved through 80 mesh to remove some agglomerates during drying, or large particles of additional ingredients, and then enter the silo for granulation after sieving. Recommended equipment rotary vibro sifter, centrifugal sifter!

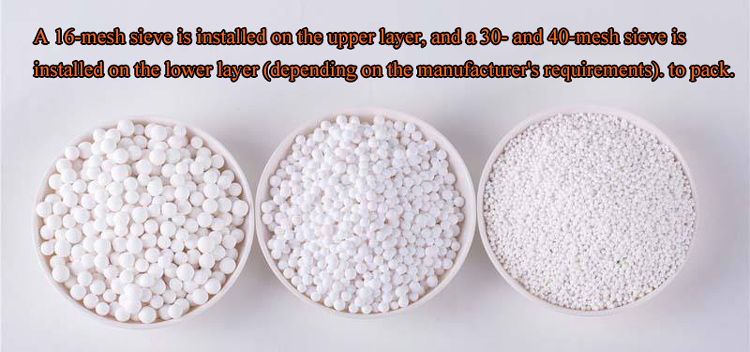

Preferably after granulation

After granulation, a 16-mesh sieve is installed on the upper layer, and a 30- and 40-mesh sieve is installed on the lower layer (depending on the manufacturer's requirements). to pack.

The finished particles are brittle and easy to break again, and the powder has a light specific gravity and poor fluidity. Front, moderate speed, both to ensure output and not broken. The bottom layer of fine powder is quickly discharged and granulated again without waste.

For the pharmaceutical industry, we have carried out humanized improvements to the two types of equipment for the cleanliness of equipment and frequent dismantling and disinfection requirements, which are more conducive to the operation of workers. In addition, the equipment can be equipped with feeding bins and dust removal equipment to improve work efficiency and reduce environmental risks.

1. The dust-free feeding station solves the problem of powder flying when manual materials are transferred, causing direct waste, and the dust environment also directly affects the health of workers. One device solves two major problems.

2. Special linear vibrating screen for particles: according to the characteristics of particles: false agglomeration, the finished particles are relatively brittle and easy to be broken again, the powder has a light specific gravity and poor fluidity, etc. Design: the upper, middle and lower layers of the screen box are made with different inclination angles; The adjusted double-amplitude and double-motors are attached to the long vibrating plate to transfer the vibration force, so that the material can be controlled in a single layer on the screen surface (1. The upper layer has false agglomerated high-throw jumping linear motion, clearing the net and jumping the ball to hit, solve the problem. False agglomeration, reducing repeated processes. 2. The middle layer of finished material, rolling forward, not throwing or jumping, moderate speed, both to ensure the output and not broken. 3. The bottom layer of fine powder, large inclination angle, large slope and short distance, quickly discharged again granulation without waste).

High quality pharmaceutical granules can be achieved with Dahan Machinery vibro sifter. Dahan Machinery has many years of experience assisting the processing industry and supplying industry leaders with a wide range of screening and filtration equipment. If you are looking for high quality and pollution-free products, please contact us today.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.